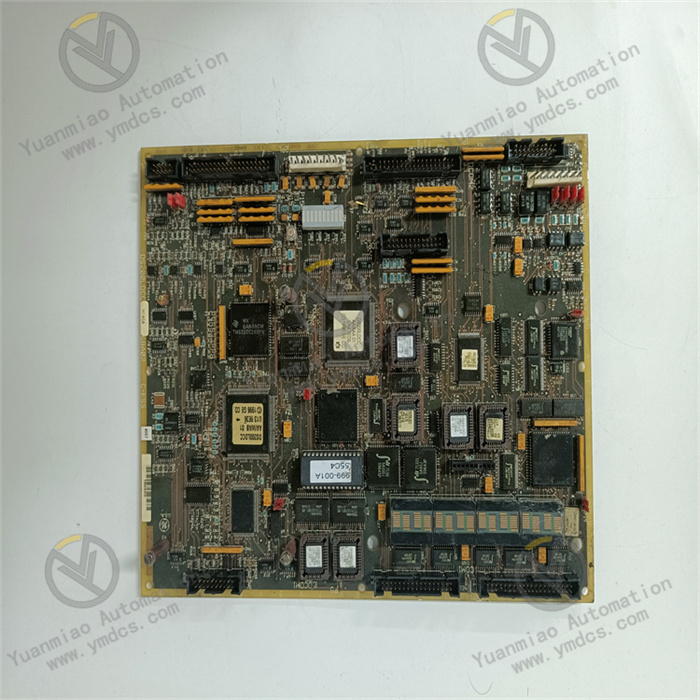

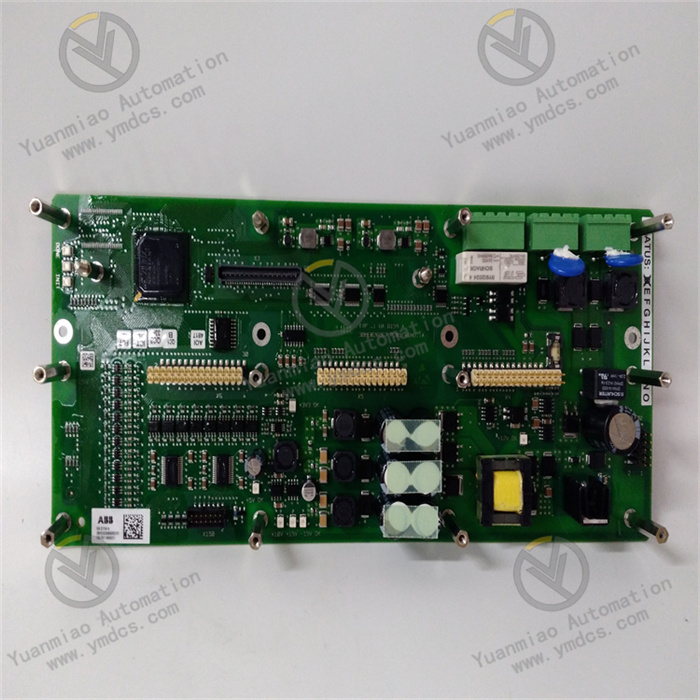

Description

Performance Characteristics: Computing Power: It has a high computing speed and data processing capability, and can quickly execute various logical and arithmetic operation instructions to meet the real-time requirements of complex industrial control tasks. For example, when dealing with a large number of analog and digital input and output signals, it can respond promptly and carry out processing. Storage Capacity: It has a certain program storage capacity and can store control programs written by users. At the same time, it also has a data storage area for saving various operation data, parameter settings, and other information. Communication Function: It supports multiple communication protocols and interfaces, enabling convenient data exchange and communication with other devices. For example, it can communicate with a host computer (such as an industrial computer) to achieve remote monitoring and management; it can also communicate with other PLCs or intelligent devices to build a distributed control system.

Main Parameters: Processor Type: A high-performance processor is adopted to ensure fast instruction execution speed and data processing capability. Working Memory: The specific size of the working memory varies according to the model. Generally speaking, it can meet the operation requirements of medium-scale industrial control programs. I/O Expansion Capability: It can be connected to multiple I/O modules to achieve the expansion of functions such as digital input and output, and analog input and output. By expanding the I/O modules, the input and output points of the system can be flexibly configured according to actual control needs. Communication Interface: It is usually equipped with communication interfaces such as Ethernet interfaces and serial ports. The Ethernet interface can be used for high-speed data transmission with other devices in the network, while the serial port can be used to connect some traditional devices or perform debugging operations. The supported communication protocols include Modbus TCP, Modbus RTU, etc., which facilitates communication and integration with different devices.

Application Areas: It is widely applied in various fields of industrial automation, such as manufacturing, energy, chemical industry, power, transportation, and other industries. It can be used to control production lines, mechanical equipment, process control systems, etc., to achieve the automatic control, monitoring, and management of equipment. For example, in the manufacturing industry, it can be used to control the operation of machine tools, robots, and other equipment; in the energy field, it can be used to monitor and control power generation equipment, substations, etc.

① 24-hour email reply (12 hours);

② For shipment to countries outside Asia, please contact the seller.

Schneider Related Products

| 140DDI85300 | 140DDM69000 |

| 140DDO35300 | 140DDO15300 |

| 140DDO84300 | 140DDO15310 |

| 140DDO88500 | 140DDO35301 |

| 140DRA84000 | 140DDO35310 |

| 140DRC83000 | 140DDO36400 |

| 140EHC10500 | 140DDO85300 |

| 140EHC20200 | 140DIO33000 |

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.