Description

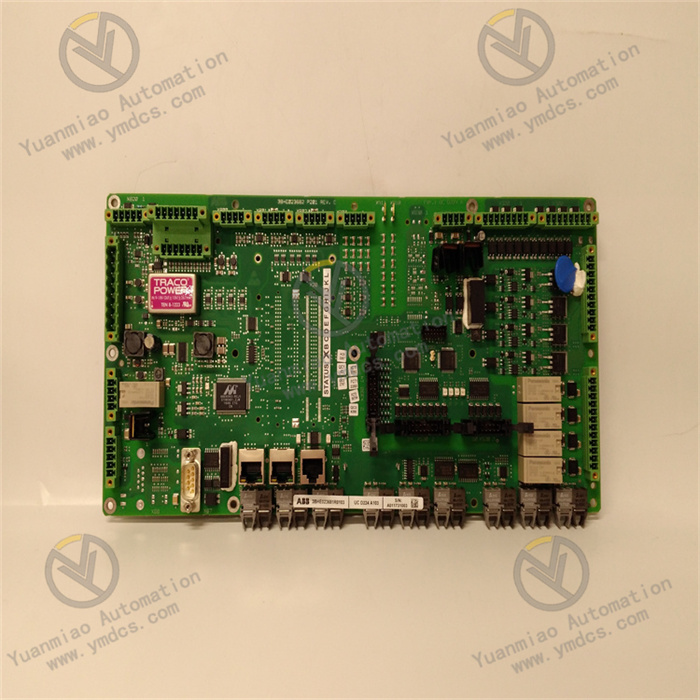

The EP3-E-4-A electric dust collector controller is a device for controlling an electric dust collector. Electrostatic precipitator is a kind of dust removal equipment widely used in the industrial field, which can efficiently remove dust and particulate matter in the air to achieve the purpose of purifying the air.

The main features of EP3-E-4-A dust removal controller include:

High efficiency dust removal: By controlling the operating parameters of the electrostatic precipitator, such as electric field strength and airflow speed, the dust removal efficiency can be effectively improved and the dust and particulate matter content in the air can be reduced. Automatic control: The controller adopts automatic control technology, which can remotely control and monitor the operating status of the electrostatic precipitator. Users can know the operation of the electrostatic precipitator in real time and control it remotely through the controller interface or network.

High reliability: The controller uses high-quality electronic components and materials, and has undergone strict quality control and testing to ensure stable and reliable work in a variety of harsh environments.

Easy maintenance: The simple design of the controller makes it easy for users to perform daily maintenance and maintenance. It also supports fault diagnosis and self-check to quickly locate and rectify faults.

Energy saving and environmental protection: Through reasonable parameter setting and control strategy, the controller can effectively reduce the energy consumption of the electrostatic precipitator and reduce the impact on the environment.

Automatic control: The controller adopts automatic control technology, which can remotely control and monitor the operating status of the electrostatic precipitator. Users can know the operation of the electrostatic precipitator in real time and control it remotely through the controller interface or network.

High reliability: The controller uses high-quality electronic components and materials, and has undergone strict quality control and testing to ensure stable and reliable work in a variety of harsh environments.

Easy maintenance: The simple design of the controller makes it easy for users to perform daily maintenance and maintenance. It also supports fault diagnosis and self-check to quickly locate and rectify faults.

Energy saving and environmental protection: Through reasonable parameter setting and control strategy, the controller can effectively reduce the energy consumption of the electrostatic precipitator and reduce the impact on the environment.

The function of the operation controller is to generate various operation control signals according to the instruction operation code and the timing signal, so as to correctly establish the data path, so as to complete the control of obtaining instructions and executing instructions. There are two kinds of controllers with different structures due to different design methods. Microoperations are non-decomposable operations that always require a corresponding control signal (called a microoperation control signal or microoperation command). A digital computer can be basically divided into two parts – the control part and the executive part. The controller is the control component, and the arithmetic device, memory, peripheral equipment is the executive component relative to the controller. A connection between the control unit and the executive unit is through the control line. The control component issues various control commands to the executive component through the control line. Usually, this control command is called a micro-command, and the operation performed by the executive component after accepting the micro-command is called a micro-operation. Another connection between the control unit and the executive unit is feedback information. The executive part reflects the operation situation to the control part through the feedback line, so that the control part can issue new micro-commands according to the state of the executive part, which is also called “state testing”. Microoperations are a set of basic operations in an executive unit. Due to the structure of the data path, microoperations can be divided into Compatibility and repulsion. In a CPU cycle of a machine, a group of microcommands that implement certain operational functions are combined to form a microinstruction. The general microinstruction format consists of operation control and sequence control. The operation control part is used to send out control signals to manage and direct the work of the whole aircraft. The sequence control part is used to determine the address to generate the next microinstruction. In fact, the function of a single machine instruction is realized by a sequence of many microinstructions. This sequence of microinstructions is often called a microprogram. Since microprograms are composed of microinstructions, when executing the current microinstruction. The address of the subsequent microinstruction must be specified so that after the execution of the current microinstruction is completed, the next microinstruction can be executed.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

Related Products

| AgilEnt 5517A | HITACHI LPD220A |

| AgilEnt 5517B | HITACHI LPD350A |

| AgilEnt 5517C | HITACHI LPF240A |

| AgilEnt 5517CL | HITACHI LPP100A |

| AgilEnt 5517D | HITACHI LPU100H |

| AgilEnt 5517DL | HITACHI LUD060A |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:https://www.ymdcs.com/ALSTOM/