Description

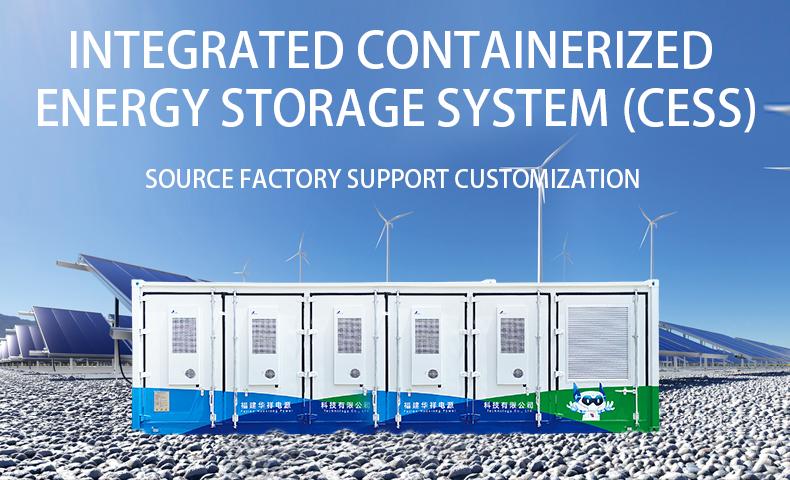

Integrated Container Energy Storage (CESS)

Safe and reliable

■ Preferred LFP route, strict safety test

■ From cell to container, hierarchical temperature control strategy, industrial temperature control system

■ All aspects of electrical protection: high and low voltage separation, insulation testing, grounding protection, lightning protection design

■ Design of 7MM thermal isolation and insulation bracket between cells

■ Module built-in aerosol fire protection measures, container intelligent bin level fire protection, hierarchical linkage, multi-layer protection

■ Battery pack is connected in series with PCS group to eliminate circulation and improve safety

Efficient and convenient

■ High efficiency, digital, intelligent EMS system architecture design

■ 0.5C charging and discharging ratio

■ Fault prediction, identification and fast location

Multidimensional integration -- Physicalization

■ Easy to transport, install and operate

■ Modular design, easy maintenance, management, expansion

Summarize

The integrated container energy storage system consists of battery cluster, energy storage bidirectional converter (PCS), battery management system (BMS), energy management system (EMS), fire control system, lighting system, dynamic ring control system, access control system, isolation transformer (optional), etc. Multiple monitoring of system status and hierarchical linkage constitute a comprehensive protection system integrating electrical safety and functional safety. Container system, standardized, prefabricated design, reduce user customization time and construction costs, reduce the security risks caused by local installation differences and management risks. Meet the regional power grid peak regulation, frequency regulation, voltage regulation, emergency response, new energy consumption and other application needs to ensure the normal operation of the power system.

System composition

1. Lithium battery cluster

The system is mainly composed of a safe, efficient and long-life lithium iron phosphate battery cell through series and parallel to form a battery module, multiple modules in series to form a battery cluster.

2. Battery management system

The core components of the system effectively protect the battery overcharge, overdischarge, overcurrent, etc., and balance the battery cell management to ensure the safe, reliable and efficient operation of the entire system.

3. Monitor the system

System operation data monitoring, operation policy management, historical data. Records, system status records, etc.

4. PCS energy storage converter

The bidirectional AC/DC converter can realize the bidirectional conversion of DC to AC and AC to DC, which can convert AC to DC, charge the battery, and convert DC to AC to supply power to the load or feed back to the grid.

5. Air conditioning system

The battery compartment integrates 1200W industrial air conditioning to meet the needs of the system in no. Smooth operation in the same environment, extending the service life of the system.

6. IP54

The whole system adopts IP54 design.

System parameter

Photovoltaic parameter

Photovoltaic access power: 400KW

Rated current: 606A

Rated input voltage: 3W+N +PE, 380/400V

Rated frequency (Hz) : 50/60

Ac parameter < Grid connection >

Rated output power (kW) : 500

Output power (kW) : 550

Rated power grid voltage (V power) : 3W+N +PE, 380/400V

Grid voltage range: -15%~ +10%

Rated network frequency (Hz) : 50/60

Power grid frequency range (Hz) : ±2

Output current harmonic: ≤3%(rated power)

Dc component: < o.5% In.

Power factor: -0.9 ^ *+0.9

Overload capacity: 105%]: continuous operation, < 105%^ 120%6] : 10min, 120%): stop operation

Ac parameter < Off-grid)

Rated output power (kVD) : 500

Output power (lkWD) : 550

Rated output voltage (V power) : 3W+N+PE, 380/400V

Output voltage harmonics: 3% (linear full load)

Rated frequency (Hz) : 50/60

Overload energy: 105%] : continuous operation, < 105%^ 120%] : 10 min, 120%): stop operation

Battery parameter

Cell type: lithium iron phosphate

Single battery cabinet power (kWh) : 215.04

Number of battery cabinets: 5

Battery system power (kwh) : 1075.2

Rated running time (h) : 2(the number of battery modules can be changed and other hours can be selected)

Battery life: 25℃ 0.5C/0.5C 100%DOD EOL80% ≥6000 times

efficiency

Efficiency: 93%

Protection

Ac switch: available

PV electric operation AC switch: available

Grid monitoring: available

Surge protection: available

Basic parameter

Size < Width * depth * height) (mm) : 6058*2438*2591

Weight. (kg) : 16000

Isolation mode: Built-in isolation change

Off-grid switching device: STS

Protection class: Outdoor IP54

Operating temperature range: -20 ~55℃(>45℃ derated)

Relative humidity Non-Condensing: 0 to 95%

Temperature control mode: air conditioning

Working altitude (m) : 4000 (>2000 RON)

Display: touch screen

Communication interface: RS485, CAN, LAN

Communication protocols: Modbus-RTU, Modbus-TCP, CAN2.0B

System characteristics

1. Safe and reliable

■ Strict safety testing of LFP routes is preferred

■ From cell to container, hierarchical temperature control strategy, industrial temperature control system

■ All aspects of electrical protection: high and low pressure separation, insulation testing, grounding protection, lightning protection design between the core 7MM thermal isolation, insulation support design

■ Module built-in aerosol fire protection measures, container intelligent bin level fire protection, hierarchical linkage, multi-layer protection

■ Battery pack is connected in series with PCS group to eliminate circulation and improve safety

2. Multi-dimensional integration

■ Easy to transport, install and operate

■ Modular design, easy maintenance, management, expansion

3. Intelligent and efficient

■ High efficiency, digital, intelligent EMS system architecture design

■ 0.5C charging and discharging ratio

■ Fault prediction, identification and fast location

FAQ

How is the early warning of the security system realized? BMS three levels, a first level of warning, the second level of alarm power reduction, three levels of power outages; temperature, smoke, combustible gas detection, the use of propane fire extinguishing, there are remote and on-site alarms, far infrared video monitoring and recording and other ways. How is ultra-high voltage converted to supply voltage? Inside the enterprise, the ultra-high voltage of the utility power is converted into supply voltage by means of a substation or transformer to supply normal equipment use and energy storage setups. Warranty issues, cycle count issues, how many cycles is a normal battery? Warranty 5 years, the first three years free of charge, the next two years to charge the cost of accessories, travel costs; the normal cycle life of the battery in 6000 The normal cycle life of the battery is more than 6000 times, 1 charging and 1 discharging per day can be used for more than 15 years, 2 charging and 2 discharging can be used for more than 8 years. How do you maximize the efficiency of 2 charging and 2 discharging? Valley-peak, flat-peak (full charge and discharge) This maximizes system utilization. What are the configuration facilities of the storage cabinets? It consists of battery pack, battery management system BMS, energy storage converter PCS, energy management system EMS, fire protection system, monitoring system and other related auxiliary systems. system, monitoring system and other related auxiliary systems, small size, large storage capacity, high temperature and low temperature resistance. What are the benefits of energy storage cabinets? (1) Shaving peaks and filling valleys, saving more than 60% of electricity costs by utilizing the peak and valley price difference. (2) Not troubled by power outages, pulling the power limit, not affecting normal production. (3) State subsidies, equipment credit for corporate income tax. (4) Emergency disaster preparedness standby. (5) Reduce carbon emissions, grid-connected operation, all benefits, data open and transparent, national grid monitoring and accounting. (6) Lithium iron phosphate battery will not trigger its own thermal runaway, no explosion, no fire. How big of a footprint do you really need for an energy storage locker, how big is 20 feet how big is 40 feet? (1) The size of 20-foot container is: 6.058*2.438*2591 meters; 40-foot container size is: 12.192*2.438*2591 meters (1.5-2 meters position is reserved around the box for maintenance). (2) 100kW-215kwh distributed energy storage cabinet indoor installation footprint in 3m weight of about 2.5T, three-sided side-by-side design covers a small area. The cabinet is designed according to the requirements of outdoor cabinet, and can be placed in the open space outside the power distribution room. Annual maintenance fee for the storage locker? Roughly, for every 1 MWh, the maintenance fee is about 10,000 yuan, the maintenance fee is less in the first 3 to 5 years, and the maintenance fee after five years is about 0.5-2% of the cost of the whole set of equipment; (investing in a 1 WKH energy storage cabinet, the investment cost is about 1,450,000 yuan, and the maintenance fee after five years is about 7,000 yuan to 28,000 yuan, depending on the degree of aging on the site)