Description

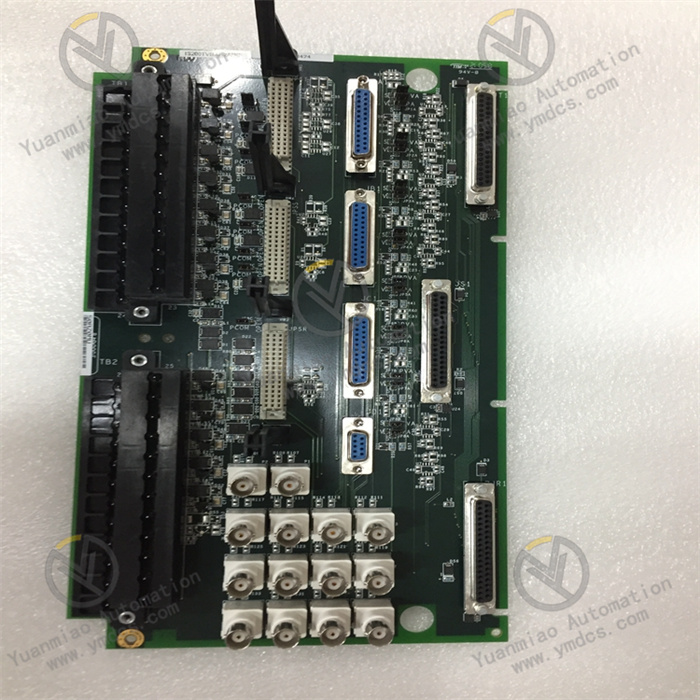

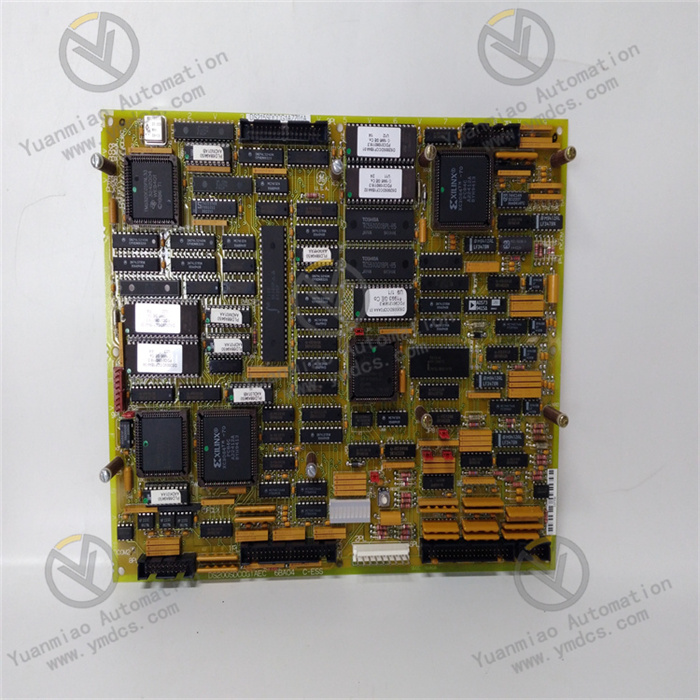

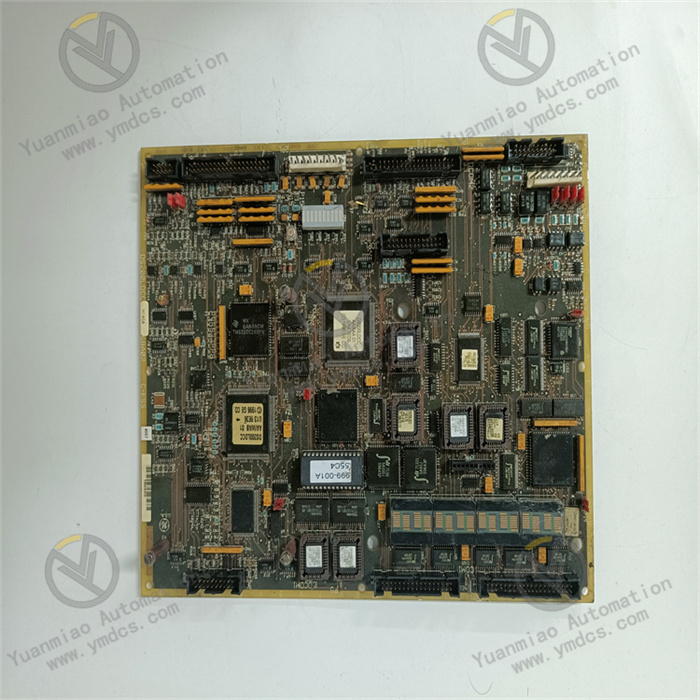

The IS215VCMIH2B is a board component for the Mark VI system manufactured by General Electric. The MKVI was one of the final steam and gas management systems released by GE under the “Speedtronic” name. This line focused on using good design and multiple backups to create reliable management systems that would increase the efficiency of the related turbines. The IS215VCMIH2B functions as a VME Bus Master Controller board. The board is designed to interface communications between the controller and the I/O boards. The IS215VCMIH2B also manages IDs for boards within the rack and associated terminal boards. There are two major versions of the VCMI board (VCMIH1/VCMIH2.) The IS215VCMIH2B has four port connections located on its front faceplate. This includes one serial port and three IONet connectors. Each IONet connector has three LED indicators placed above it. These are labeled “TX,”“RX,” and “CD.” The board also has LED indicators labeled Run/Fail/Status (placed above a push button reset switch,) and four LEDs labeled 1,2,4, and 8. The faceplate connects to the main board using screws. The IS215VCMIH2B is a 6U high VME board that is .0787 inches wide. It has a Texas Instruments 32-bit digital signal processor and 32-bit transfer configuration SRAM, 256k x 32. The board has two backplanes, a single 12-pin vertical male connector, (p5,) and several connectors made from conductive dots. The board uses integrated circuits, resistors, capacitors, and diodes. There are three transformers located near the front edge. The board has several transformers and over forty inductor beads.

PCB circuit board (printed circuit board), also known as printed circuit board, printed circuit board, referred to as printed board, English referred to as PCB(printed circuit board) or PWB(printed wiring board), with insulation board as the base material, cut into a certain size, which is at least one conductive graphic, Holes (such as component holes, fastening holes, metallization holes, etc.) are used to replace the chassis of the previous device electronic components, and to realize the mutual connection between the electronic components. Because this board is made by electronic printing, it is called "printed circuit board". It is not exact to call "printed circuit board" "printed circuit" because there is no "printed component" on the printed board and only wiring. Basic composition The current circuit board is mainly composed of the following: 1, line and Pattern: The line is used as a tool for conducting between the originals, and a large copper surface will be designed as a grounding and power layer in the design. The lines and drawings were made simultaneously. 2, Dielectric layer (Dielectric) : used to maintain the insulation between the line and the layers, also known as the substrate. 3, Through hole (via) : through holes can make more than two levels of the line through each other, the larger through holes are used as parts plug-in, and non-through holes (nPTH) are usually used as surface mount positioning, assembly fixing screws. 4, Solder resistant ink (Solder resistant /Solder Mask) : not all the copper surface will eat the tin parts, so the non-tin area will be printed with a layer of material to prevent the copper surface from eating tin (usually epoxy resin) to avoid short circuit between non-tin lines. According to different processes, it is divided into green oil, red oil and blue oil. 5, Legend /Marking/Silk screen: this is not necessary, the main function is to mark the name of each part on the circuit board, the position of the box, convenient after assembly maintenance and identification. 6, Surface treatment (Surface Finish) : because the copper surface is easily oxidized in the general environment, it can not be tin (poor soldering), so it will protect the copper surface to eat tin. The way of protection is to spray Tin (HASL), gold (ENIG), Silver (Immersion Silver), tin (Immersion Tin), organic flux (OSP), and each method has advantages and disadvantages, collectively referred to as surface treatment. Wechat public number: Shenzhen LED network (ID:SZLEDCOC)

PCB Features of printed circuit boards Electrical conductivity This is due to the fact that the PCB is made of conductive materials and printed on the board through a special printing process. This conductive property not only performs well at small current, but also maintains low signal loss at high frequencies, which is conducive to achieving high-quality signal transmission. Reliability and stability In the PCB manufacturing process, professional process flow and strict quality control are used to ensure the accurate layout and precise size of the circuit line. This enables the PCB to withstand complex working conditions such as high temperature and high humidity in various extreme environments, and also enhances the anti-interference ability of electronic equipment, effectively improving the service life of the equipment. Maintainability Compared to the traditional point-to-point welding method, the PCB adopts a modular design, and the electronic components are welded to a specific location on the board to form a complete circuit connection. This makes the maintenance process easier, only need to replace or weld specific modules, without the need to rebuild the entire circuit, greatly saving maintenance time and cost. expandability Because the PCB uses a layered design, the circuit with different functions can be laid out on different board layers, so as to achieve a more complex and diversified circuit design. This makes PCBS very flexible in the mass production process and able to meet the changes in circuit layout and functional requirements of different electronic devices.

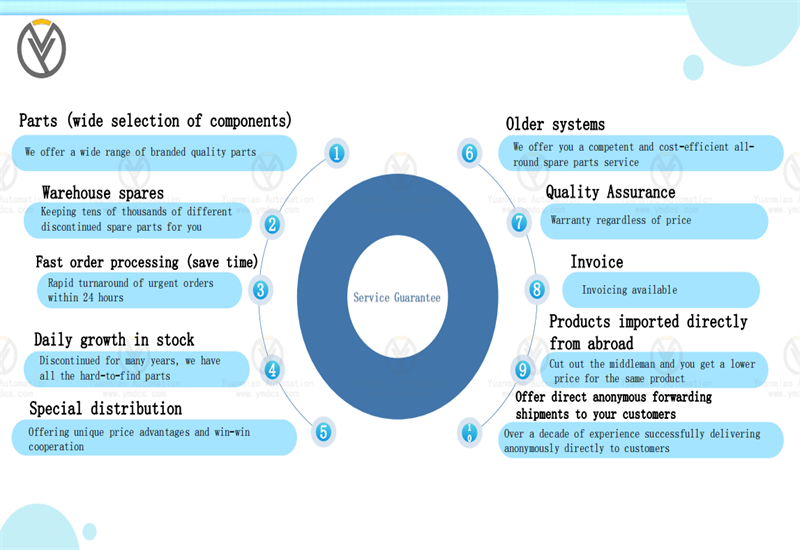

The company focuses on DCS, PLC, robot, large servo four systems

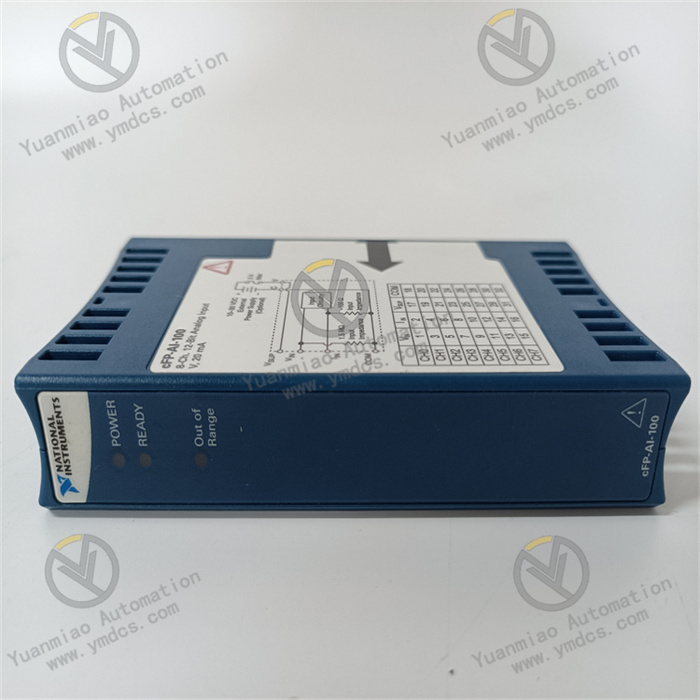

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

General Electric Related Products

| DS200FHVAG1A | DS200DMCAG1AGC |

| DS200FPSAG1A | DS200DMCAG1AHC |

| DS200FSAAG1A | DS200DMCBG1ABA |

| DS200FSAAG2A | DS200DMCBG1ACB |

| DS200GDPAG1A | DS200DMCBG1ACC |

| DS200IMCPG1C | DS200CVMAG1AEB |

| DS200IPCDG2A | DS200DTBAG1AAA |

| DS200IPCSG1A | DS200DTBDG1ABB |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/GE/