Description

9907-205 Technical Specifications

Electrostatic Discharge:15 kV

Manufacturer:Woodward

Max Nodes per Bus:20 (+40 to +85 °C)

Maximum Stub Length:600 mm (0 to +70 °C)

Series:MSLC

The Woodward 9907-205 is a hand-held programmer. Model 9907-205, is part of the MSLC series, or Master Synchronizer and Load Control series which is produced by Woodward Inc. The 9907-205 has a multitude of functions. Some of the tasks that are within its power include synchronization, utility load sensing, control capabilities over import and export load levels, power factoring, and a master process control capability.

The 9907-205 model is designed as the MSLC Hand Held Programmer module. This allows for the operators to be able to monitor the generator’s standard parameters, and runs diagnostics on its contact switches and the analog input and output ports. This also helps in reducing the amount of time spent installing and troubleshooting, by letting users be able to set up the control functionality and specifications prior to powering up the system.

While operating be on the lookout for potential problems or technical issues, one of the technical issues that may come up during operating is a remote load reference input. You can run what is known as a bench test to ensure that your control is functioning properly. The test you will perform to check the remote load reference input is supposed to make sure that the operation, as well as calibration, are both correct. If you need to calibrate the remote input you should go to the calibration menu and select option number six and set the key to forty-nine.

Woodward 9907-205 Handheld Programmer | Digital Speed Control for Reciprocating Engines | Enhanced Steady-state Dynamics | EU Directive Compliant Simple Type: Handheld Programmer The Woodward 701A Digital Speed Control offers improved speed control with models designed specifically for low-speed to highspeed diesel, gas, or pilot-fuel engines (one actuator moving two sets of linkages to the gas fuel valve and the diesel injection system). The 701A control uses a 16-bit microprocessor for all control functions. The control has enhanced control dynamicsthat give smooth steady-state operation, yet the control retains fast response to engine speed and load changes. An external contact input allows switching between two independent sets of automatic variable dynamics. This is especially useful for engine systems with different operation conditions, such as open or closed clutches or pilot-fuel engines. The contact could also be wired to change dynamics based on utility tie breaker status.

Features

Adaptive (learning) Speed-sensing Algorithm

Enhanced Steady-state Dynamics

EU Directive Compliant

Generator Set and Other Constant-Speed or Variable-Speed Applications

Reduced Cost

Remote Speed Setting

Self Diagnostics

Start, Load, and Torque Limiters

Tachometer or Load signal Output

Two Independent-Sets of Engine mapped Variable Dynamics

easYgen-3200 series parallel control module features

1. The home page display screen can be configured, and 2 editable screens are used to monitor user-defined data;

2. High flexibility and easy setup;

3. Realize the functions of external PLC through internal logic management/analog management function;

4. Isolated measurement input, relay output, analog output and communication channel enhance the external anti-interference ability of the system;

5. Devices can be connected via Ethernet or USB, with online use of documents and system update functions, enhancing the maintainability of customer systems;

6. With complete city network, generator and engine protection function, no additional use of power detection protection relay;

7. Built-in 14 languages, can cope with the use of various regions;

8. Can detect generator parameters, mains parameters and bus parameters, perfect city network, generator and engine protection;

9. Support up to 32 generator units to be connected to the grid, with shear peak, standby, AMF and other modes, emergency operation or input/output operation of the municipal network;

10. Can control the open/close transfer control of up to 2 circuit breakers;

11. Active and reactive load distribution and scheduling start-up function between generators with the same or different rated power;

12. Logic management and simulation management functions can meet the complex control requirements of customers;

13. With 3 Pids that can be freely configured.

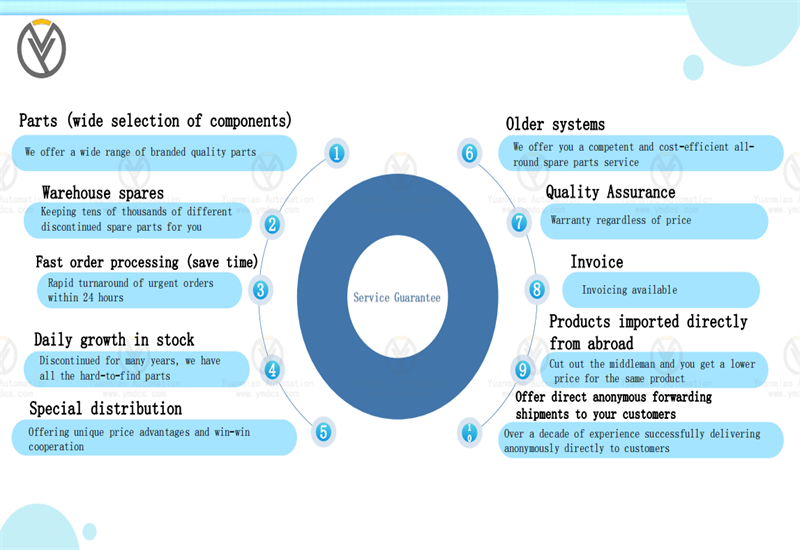

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

Related Products

| WOODWARD 9907-162 | WOODWARD 5466-348 |

| WOODWARD 9907-164 | WOODWARD 5466-351 |

| WOODWARD 9907-165 | WOODWARD 5466-352 |

| WOODWARD 9907-167 | WOODWARD 5466-353 |

| WOODWARD 9907-252 | WOODWARD 5466-355 |

| WOODWARD 9907-838 | WOODWARD 5466-411 |

| WOODWARD 5403-535 | WOODWARD 5466-419 |

| WOODWARD 5403-536 | WOODWARD 5466-425 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Woodward/