Description

1. When the data in the monitoring screen shows the following conditions, it indicates that there is a problem with the control system. Microcomputer maintenance personnel should immediately notify the maintenance personnel, the operator should go to the scene to deal with.

(1) Frequently changing data remain unchanged for a long time, and some or all data remain unchanged.

(2) On the control group screen, manual and automatic switching is not possible, or after manually entering the data, once confirmed, it returns to the original data and cannot be modified.

(3) On the trend chart screen, several trends remain unchanged as straight lines.

(4) On the monitoring screen, multiple data fluctuate greatly at the same time.

Determine whether the fluctuation data is related to the process parameters. If it is a relevant parameter, notify the instrument and microcomputer personnel to check whether there is a certain adjustment system fluctuation caused by the change of the relevant parameter. At the same time, the relevant adjustment system is set to manual mode and adjusted on site if necessary. In an aqueous solution complete cycle device, when the pressure of the urea synthesizer is normal, it is l9.67mpa. If there is a sudden large-scale fluctuation, it will inevitably lead to pressure fluctuations in the downstream middle and low pressure system. The reason for this is that a fluctuation in one of several relevant parameters causes a change in the other parameters, rather than a failure of the control system itself. If there is no direct interaction in terms of fluctuating data technology, it may be due to some kind of card failure on the microcomputer. Immediately set up the corresponding automatic adjustment system for manual adjustment, and adjust on site if necessary. At the same time inform the microcomputer and instrument personnel to check.

2. Check the operating status of the operation station. When an operating station crashes, the monitoring screen data does not refresh, the adjustment screen does not work, check whether the alarm indicator in the upper right corner of the system is normal, and check whether other operating stations are working normally. If it's normal, it's only the operating station. Notify the microcomputer repairman for repair. If the data of other operating stations remains unchanged, it indicates that the system communication network has failed. Immediately notify maintenance personnel to check the operation of network equipment and make repairs.

3. Observe the power failure of the operation station. If some operating station suddenly does not show, it means that the UPS or main power supply has been turned off, and immediately notify the microcomputer maintenance staff to perform maintenance. If the operating station with power can be monitored normally, the normal adjustment of the control system will not be affected at this time.

4. Pay attention to the power failure of all control station equipment. Since all console devices are powered by dual circuits, a UPS, and a power supply, this is unlikely to happen. When the control station is completely powered off, the two systems send an alarm, a red light goes on the monitoring screen, communication is interrupted, and all data is not refreshed. All the self-regulating systems are completely out of control, and the regulating valve will return to its initial state, with the valve fully closed and the valve fully open. In this case, emergency treatment or parking should be carried out immediately, while the operation is carried out on site.

5. Pay attention to the power failure of all operating stations. In this case, check whether the power indicator of the control station is normal and whether the card diagnosis indicator is faulty. Red and green indicator cards are working properly. If the above conditions are normal, you can confirm that the control station works normally and the automatic adjustment system works normally. However, the operator is temporarily unable to see the monitoring screen or perform remote control operations on the site. Immediately notify the microcomputer maintenance personnel for maintenance and on-site monitoring.

6. When multiple self-regulating systems are found to be faulty, and the self-regulating valve position on the monitoring screen is fully open or fully closed, immediately check the air supply pressure of the instrument. If the air supply pressure is less than 0.4 pa, this is not normal. Check the air supply line for blockage or leakage; If the air source pressure is less than 0.2MPA, immediately shut down. Turn all self-regulating systems on the monitor screen to manual mode, adjust the valve position of the regulator to a safe position, notify the instrument technician to check the air source, and operate on site. Close the stop valves at both ends of the regulator and use the bypass valve to operate.

Conclusion: When DCS fails, operators should master certain identification met

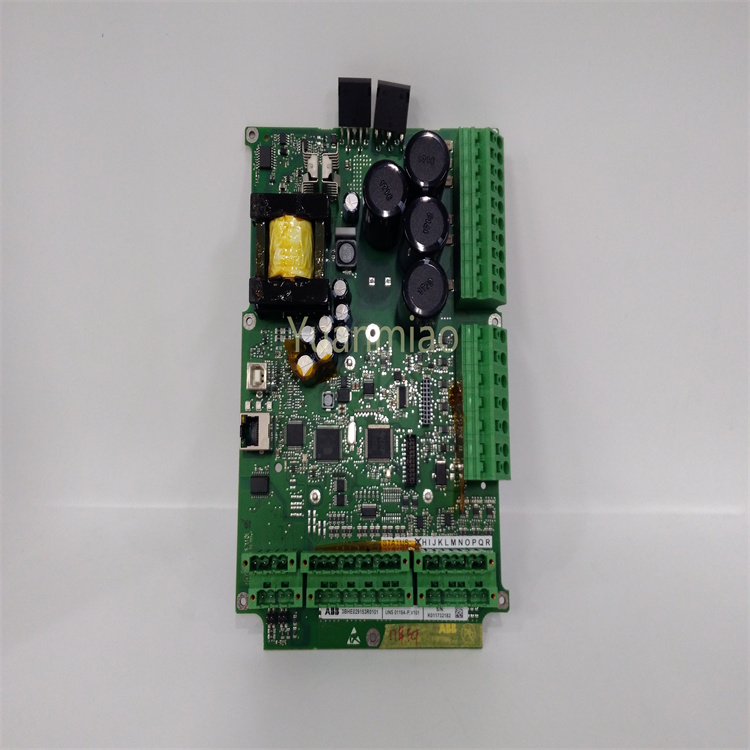

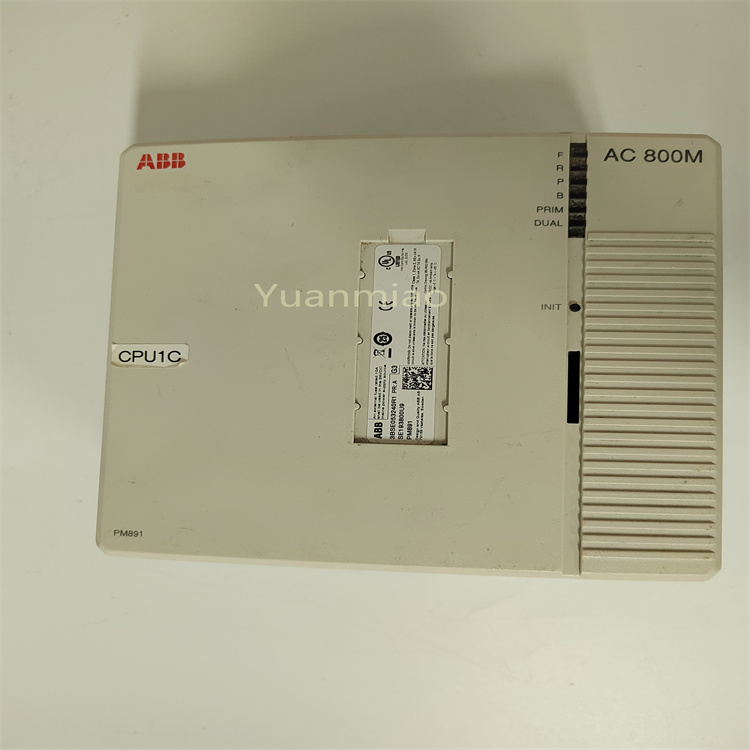

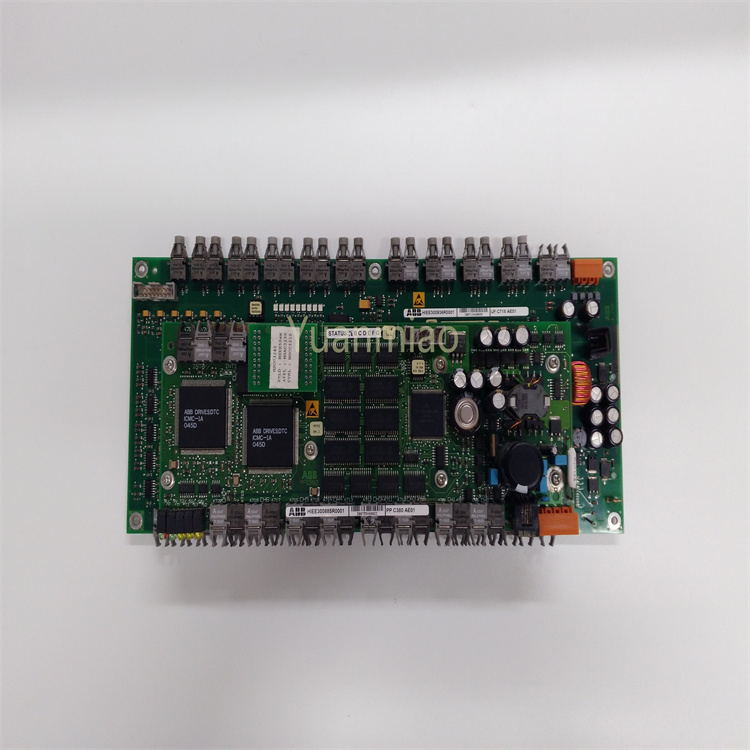

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

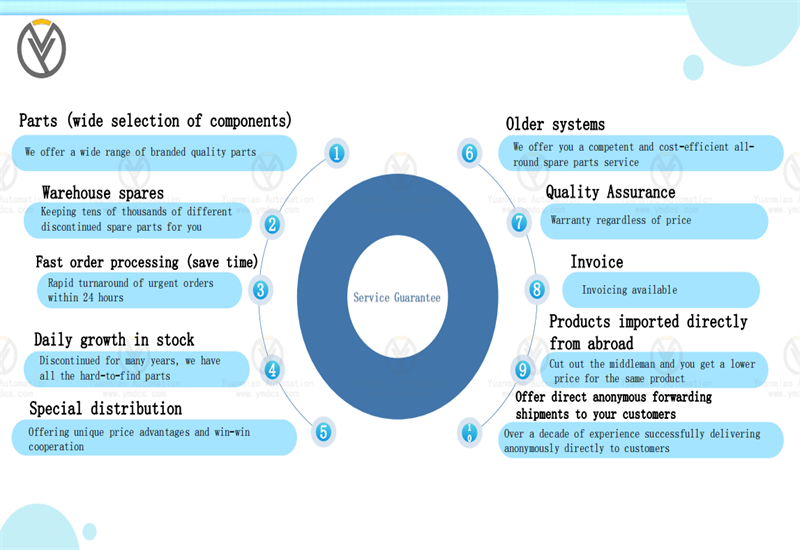

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

General Electric Related Products

| IS200BLIGH1A | IS200DTAOH1ABA |

| IS200BPIAG1A | IS200ECTBG1ADE |

| IS200BPVCG1B | IS200EDCFG1ADC |

| IS200DSPXH2C | IS200EMIOH1ACA |

| IS200DSVOH1B | IS200EPDMG1ABA |

| IS200DTAIH1A | IS200EISBH1AAB |

| IS200EDEXG1A | IS200ERGTH1AAA |

| IS200DTCIH1A | IS200EPSMG1ABB |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/GE/