Description

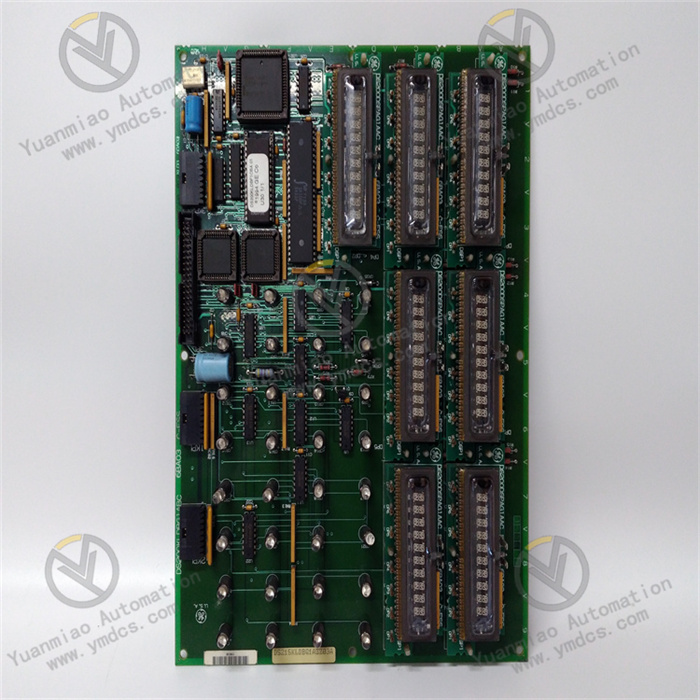

GE IS200WSVOH1ADD

I. Overview

The GE IS200WSVOH1ADD is a compact, high-precision analog output module for distributed control systems. Its core value lies in providing a "high-density, high-precision, and highly reliable" analog command execution solution for space-constrained industrial control scenarios. Through a "4-channel independent configuration + compact structure + wide-temperature design", it converts digital commands from the Mark VIe controller into standard 4-20mA/0-10V DC analog signals to drive actuators such as control valves and frequency converters. It is suitable for auxiliary control of small steam turbines, regulation of small chemical reactors, and municipal equipment control, making it a key I/O component ensuring stable process parameters in compact spaces.

This module adopts a miniaturized PCB design, supports rack-level redundancy configuration for the Mark VIe system, and enables parameter calibration and fault diagnosis in conjunction with ControlST software. It is widely used in global industrial process control fields, particularly in small and medium-sized control loops requiring "small size + high precision".

II. Technical Specifications

(I) Core Signal Conversion and Output Parameters

1. Output Channel Configuration (Key Differences from IS210WSVOH1AE)

- Number of Channels: 4 independent analog output channels (fewer than the 8 channels of the IS210, focusing on compact requirements), with each channel supporting software-configurable signal types:

- Current Output: 4-20mA DC, load impedance 10Ω-600Ω (full-scale output, compatible with more types of actuators), short-circuit protection current ≤30mA (self-recovering, with a higher protection threshold);

- Voltage Output: 0-10V DC/±10V DC (newly added bipolar output, compatible with actuators requiring reverse regulation), load impedance ≥1kΩ, overvoltage protection threshold 18V DC (clamping protection, with a wider tolerance range);

- Output Accuracy:

- Current Output: ±0.03% FS (at 25℃ ambient temperature, more accurate than the ±0.05% of the IS210), ±0.08% FS (within the -10℃-65℃ operating temperature range);

- Voltage Output: ±0.05% FS (at 25℃ ambient temperature, more accurate than the ±0.1% of the IS210), ±0.15% FS (within the -10℃-65℃ operating temperature range);

- Resolution: 16-bit DAC (consistent with the IS210), minimum output step: 0.3125μA for current output (4-20mA range), 0.195mV for voltage output (0-10V range)/0.391mV (±10V range).

2. Signal Conversion and Dynamic Characteristics

- Conversion Response Time: From digital command update to stable analog output (within ±0.1% FS error) ≤8ms (faster than the 10ms of the IS210, suitable for fast-regulation scenarios);

- Linearity: ≤±0.01% FS (within the full-scale range, better than the ±0.02% of the IS210), with no inflection point nonlinear deviation;

- Temperature Drift Characteristics: ±3ppm/℃ (current output), ±8ppm/℃ (voltage output). Within the -10℃-65℃ temperature fluctuation range, the output deviation is negligible, and the calibration cycle is extended to 12 months (6 months for the IS210).

(II) Electrical and Environmental Parameters (Upgraded Adaptability Features)

1. Power Supply and Power Consumption

- Power Supply Method: Powered via the backplane of the Mark VIe standard I/O rack (24V DC redundant power supply, compatible with 18V-30V wide-voltage fluctuations). The rated power consumption of a single module is ≤5W (4 channels at full-load output, lower than the 8W of the IS210, resulting in lower energy consumption);

- Power Supply Protection: Newly added surge protection (IEC 61000-4-5, ±2kV surge tolerance), combined with reverse polarity protection, overcurrent protection (automatic current limiting when total overcurrent ≤0.8A), and undervoltage protection (output maintains "last value" state when power supply voltage <18V DC);

- Isolation Performance:

- Inter-channel Isolation: 3000V AC (withstand voltage for 1 minute, higher than the 2500V of the IS210), preventing signal crosstalk between channels;

- Channel-to-Backplane Isolation: 2000V AC (withstand voltage for 1 minute, higher than the 1500V of the IS210), common-mode interference resistance of ±300V DC (better than the ±250V of the IS210).

2. Environmental Adaptability (Enhanced Industrial Scenario Adaptation)

- Operating Environment: Temperature range of -10℃-65℃ (wider than the 0℃-60℃ of the IS210), storage temperature range of -40℃-85℃, relative humidity of 5%-95% RH (no condensation, supporting short-term 98% RH humid environments);

- Protection Class: The module itself has an IP20 protection class (consistent with the IS210). The PCB board is coated with an enhanced conformal coating (resistant to salt spray and mold, complying with IEC 60068-2-11 standards), making it suitable for harsh environments such as coastal chemical plants and hot and humid areas in southern regions;

- Electromagnetic Compatibility: Passed IEC 61000-4-2 (±15kV air discharge/±8kV contact discharge), IEC 61000-4-4 (±4kV electrical fast transient), and IEC 61000-4-6 (20V/m radio frequency radiation) tests, with better anti-interference capabilities than the IS210.

(III) Communication and System Compatibility Parameters

1. Communication Interfaces and Redundancy

- Backplane Communication: Communicates with the main controller (e.g., IS200TBSCH1A) via the dedicated high-speed backplane bus of the Mark VIe I/O rack (100Mbps). The data update cycle is ≤4ms (faster than the 5ms of the IS210), supporting deterministic control command transmission;

- Redundancy Support: Supports rack-level redundancy (consistent with the IS210) and adds a "module-level hot-swap" function (the IS210 only supports rack-level redundancy). A faulty single module can be replaced online, with a switching time ≤1ms;

- Diagnostic Communication: Built-in enhanced diagnostic chip, capable of reporting 12 types of faults (8 types for the IS210) such as channel short circuit/overload, DAC abnormality, and power fluctuation, supporting remote calibration and fault reset.

2. System Adaptability

- Software Support: Compatible with GE ControlST V10.0 and above, adding a "channel grouping configuration" function (4 channels can be divided into 2 groups for independent control) and supporting batch setting of fail-safe values;

- Device Compatibility: Directly compatible with GE Rosemount 3051S transmitters and Fisher DVC6200S intelligent valve positioners, and compatible with third-party bipolar actuators (e.g., ±10V servo valves).

III. Functional Differences from IS210WSVOH1AE

| Comparison Dimension | GE IS200WSVOH1ADD (Compact Upgraded Version) | GE IS210WSVOH1AE (Standard Version) |

|---|---|---|

| Core Positioning | Compact scenarios, high precision + bipolar output | Standard scenarios, high density (8-channel) output |

| Number of Channels | 4 independent channels | 8 independent channels |

| Output Type | 4-20mA/0-±10V DC (bipolar) | 4-20mA/0-10V DC (unipolar) |

| Output Accuracy | ±0.03% FS (current)/±0.05% FS (voltage) | ±0.05% FS (current)/±0.1% FS (voltage) |

| Response Time | ≤8ms | ≤10ms |

| Environmental Adaptation | -10℃-65℃, salt spray resistance, ATEX explosion-proof certification | 0℃-60℃, basic moisture resistance, no explosion-proof certification |

| Protection and Isolation | 3000V channel isolation, ±2kV surge protection | 2500V channel isolation, no surge protection |

| Power Consumption and Size | ≤5W, 20% smaller size | ≤8W, standard size |

| Special Functions | Module-level hot-swap, channel grouping configuration | Only rack-level redundancy, no grouping configuration |

IV. Functional Features

(I) Compact Design + High Precision, Suitable for Space-Constrained Scenarios

The 4-channel layout and 20% size reduction allow installation in small control cabinets or distributed I/O stations. For example, in the auxiliary control of small gas turbines, one IS200WSVOH1ADD module can replace two traditional 2-channel analog output modules to drive fuel control valves (4-20mA), cooling fan frequency converters (0-10V), lubricating oil pump frequency converters (0-10V), and exhaust valve actuators (±10V bipolar regulation). It achieves 4-channel precise output in a 1U-high control cabinet, increasing space utilization by 50%.

(II) Bipolar Output + Wide Load Adaptation, Covering Diverse Actuators

The newly added ±10V bipolar voltage output can directly drive actuators requiring reverse action (e.g., servo valves, bidirectional control valves) without the need for additional signal conversion modules. In the control of small chemical reactors, the module outputs ±10V signals to drive the stirring shaft servo valve, realizing forward and reverse speed regulation of the stirring speed (-10V corresponds to the maximum reverse speed, +10V corresponds to the maximum forward speed). The regulation accuracy is ±0.1% FS, meeting the mixing uniformity requirements of the reactor.

(III) Enhanced Environmental Adaptation and Explosion Protection, Expanding Application Boundaries

- Harsh Environment Adaptation: The enhanced conformal coating and -10℃-65℃ wide-temperature design enable stable operation in salt spray environments of coastal chemical plants and hot and humid areas in southern regions. The module lifespan is 30% longer than that of the IS210;

- Explosion-Proof Certification: The ATEX explosion-proof certification allows it to be used in Zone 2 explosion-proof scenarios in the petrochemical industry (e.g., level regulation of small storage tank areas). It achieves safe control in conjunction with explosion-proof actuators without the need for additional explosion-proof control cabinets.

(IV) Module-Level Hot-Swap + Enhanced Diagnostics, Reducing Maintenance Difficulty

It supports online hot-swap replacement (the IS210 requires shutdown for replacement). In the control of dosing pumps in municipal water treatment plants, maintenance personnel can directly pull out and replace faulty modules, with a replacement time ≤2 minutes, without interrupting the dosing process. The enhanced diagnostic function can monitor changes in channel load in real time. When poor contact of actuator cables causes abnormal load impedance, it immediately reports a "load abnormal" fault, avoiding regulation deviations caused by signal attenuation.

V. Application Fields

(I) Power Industry: Auxiliary Control of Small Steam Turbines/Generators

- Fuel Regulation of Small Gas Turbines: The module outputs 4-20mA signals to drive fuel control valves, and in conjunction with the Mark VIe controller, realizes precise speed control of 3000rpm. The ±0.03% FS accuracy ensures a speed fluctuation ≤±1rpm, making it suitable for small generator sets below 10MW;

- Generator Excitation Regulation: It outputs 0-10V signals to control the excitation regulator, stabilizing the generator terminal voltage at 10kV±0.5%. The temperature drift of ±3ppm/℃ ensures no significant voltage fluctuation when the ambient temperature changes.

(II) Chemical Industry: Control of Small Reactors and Storage Tanks

- Temperature Control of Laboratory-Grade Reactors: The module outputs 4-20mA signals to drive jacket cooling water control valves, and in conjunction with PT100 temperature sensors, realizes reactor temperature control of 80℃±0.5℃. The 8ms fast response avoids temperature overshoot;

- Level Regulation of Small Storage Tanks: It outputs ±10V signals to drive bidirectional level control valves (feeding/discharging). When the level is below the set value, it outputs +5V to open the feeding valve; when the level is above the set value, it outputs -5V to open the discharging valve. The level control accuracy is ±2mm.

(III) Municipal Industry: Distributed Water Treatment Equipment

- Aeration Control of Small Sewage Treatment Stations: The module outputs 4-20mA signals to drive aeration valves, adjusting the aeration volume based on feedback from dissolved oxygen sensors (0-20mg/L). The dissolved oxygen control accuracy is ±0.3mg/L, and the low-power design makes it suitable for remote stations powered by solar energy;

- Pressure Control of Secondary Water Supply in Residential Areas: It outputs 0-10V signals to control water supply pump frequency converters, stabilizing the pipe network pressure at 0.4MPa±0.02MPa. The module-level hot-swap function ensures no water supply interruption during maintenance.

(IV) Industrial Auxiliary: Small Production Lines and Equipment

- Temperature Regulation of Electronic Component Packaging Equipment: It outputs 4-20mA signals to drive heater controllers, realizing packaging temperature control of 150℃±1℃. The ±0.01% FS linearity ensures temperature uniformity;

- Speed Control of Small Conveyor Belts: It outputs 0-10V signals to control conveyor belt frequency converters, with a speed regulation range of 0-1m/s and an accuracy of ±0.001m/s, meeting the stability requirements for electronic component transportation.

VI. Selection and Engineering Implementation Recommendations

(I) Selection Criteria

- Space and Channel Requirements: This module is preferred for control cabinets with limited space (e.g., 1U height) and requiring 4 or fewer analog output channels; the IS210WSVOH1AE is selected for requirements of 8 or more channels;

- Actuator Type: This module is more suitable for scenarios requiring bipolar regulation (e.g., servo valves, bidirectional valves) or a load impedance ≤600Ω; the IS210 can be selected for unipolar actuators with a load ≤500Ω;

- Environment and Safety: This module must be selected for coastal/hot and humid/explosion-proof scenarios (Zone 2); the IS210 can be selected based on cost for conventional environments without explosion-proof requirements.

(II) Recommended Peripheral Configuration

- Actuator Adaptation: For bipolar regulation, the GE DS200 series servo valves (±10V input) are preferred; for current-type actuators, the Fisher DVC6200S (4-20mA, 250Ω load) is selected;

- Power Supply Configuration: It is matched with the Mark VIe standard redundant power supply IS200PWRCH1A (24V DC/10A); for explosion-proof scenarios, an explosion-proof power supply (e.g., Phoenix Contact EX 24V DC) must be selected;

- Wiring Specifications: Twisted shielded cables (cross-sectional area 0.5mm²) are used for bipolar signal cables; the shield layer is grounded at both ends (explosion-proof scenarios must comply with ATEX grounding requirements); the distance from power cables is ≥200mm (metal partitions can be used for isolation in compact cabinets).

(III) Installation and Commissioning Notes

- Installation Specifications: The module must be installed in a Mark VIe standard mini cabinet (e.g., IC698CAB050), with a distance of ≥15mm from other modules to ensure heat dissipation; for explosion-proof scenarios, it must be installed in an Ex d IIB T4 explosion-proof box, and cable entry must use explosion-proof sealing joints;

- Parameter Configuration: The ControlST software is used to configure the channel signal type (note the distinction between unipolar/bipolar), fail-safe value (e.g., 0V or 4mA output when power is off); bipolar channels require calibration of positive and negative full scales (e.g., -10V, 0V, +10V);

- Commissioning and Verification:

- Bipolar Test: Input -100%, 0%, +100% digital commands, and check if the output voltage is -10V, 0V, +10V, with an error ≤±0.05% FS;

- Hot-Swap Test: Pull out the module while powered on, and confirm that the standby module takes over the output within 1ms without signal interruption;

- Explosion-Proof Test: For explosion-proof scenarios, loop insulation testing (insulation resistance ≥100MΩ) and grounding resistance testing (≤1Ω) must be performed.