Description

The Horizontal Mini Series PillowBlock load cells for the web processing industries have the same dimensions as conventional load cells and mount in the same way. But they measure only the horizontal force component of the web tension. Unlike load cells that measure along the vertical axis, they are not forced to sense the roll weight along with the web tension. So these load cells can be sized to the tension level alone, and function at the high end of their measuring range, where load cells perform best. The result: always optimal tension measurement performance – even when rolls are heavy and tension light. Quality load cells that eliminates drift and recalibration Wide operating range Easy to apply

The horizontal Mini series pillow block load units for the Web processing industry have the same dimensions as conventional load units and are installed in the same way. But they only measure the horizontal force component of the network tension. Unlike load units that are measured along a vertical axis, they are not forced to sense the weight of the roll at the same time as the network tension. In this way, these load cells can be individually adjusted to the tension level and operate at the high end of their measurement range, where the load cells perform best. The result: Always the best tension measurement performance - even if the reel is heavy and the tension light. High quality load cells that eliminate drift and recalibrate the operating range for easy application, the first sensor sensor was developed in Vstross, Sweden in the early 1950s and patented in 1954. The well-known pressure sensor synthesis technique is a measurement principle based on the magnetoelastic effect - the magnetic properties of a material are affected by the mechanical forces applied to it. When subjected to mechanical forces,ABB's pressure sensor sensors produce a measurement signal due to changes in the magnetic field. (Move your mouse over the illustration to see these changes.) Because these signals are not affected by physical motion or deformation, the load unit combines sensitivity and a special tolerance for overload, with virtually no inherent limit on the number of load cycles. ABB Pressure Sensors The sensor produces a high-power, low-resistance AC signal that is very resistant to electrical interference and ground failures.

Pressure Transducer is a device or device that can feel the pressure signal and convert the pressure signal into an available output electrical signal according to a certain law. The pressure sensor usually consists of a pressure sensing element and a signal processing unit. According to different test pressure types, pressure sensors can be divided into gauge pressure sensors, differential pressure sensors and absolute pressure sensors. Pressure sensor is the most commonly used sensor in industrial practice, which is widely used in various industrial automatic control environments, involving water conservancy and hydropower, railway traffic, intelligent buildings, production automatic control, aerospace, military, petrochemical, oil Wells, electric power, ships, machine tools, pipelines and many other industries. Working principle Piezoresistive pressure sensor Resistance strain gauge is one of the main components of piezoresistive strain sensor. The working principle of the metal resistance strain gauge is that the strain resistance adsorbed on the substrate material changes with mechanical deformation, which is commonly known as the resistance strain effect. Ceramic pressure sensor The ceramic pressure sensor is based on the piezoresistive effect, the pressure directly acts on the front surface of the ceramic diaphragm, causing the diaphragm to produce a small deformation. The thick film resistor is printed on the back of the ceramic diaphragm and connected to a Wheatstone bridge. Due to the piezoresistive effect of the varistor, the bridge generates a voltage signal that is linear in height and proportional to the pressure and also proportional to the excitation voltage. The standard signal is calibrated to 2.0/3.0/3.3mV/V according to different pressure ranges, which can be compatible with strain gauge sensors. Diffused silicon pressure sensor The working principle of the diffused silicon pressure sensor is also based on the piezoresistive effect, using the piezoresistive effect principle, the pressure of the measured medium directly acts on the diaphragm of the sensor (stainless steel or ceramic), so that the diaphragm generates a micro displacement proportional to the pressure of the medium, so that the resistance value of the sensor changes, and the electronic circuit is used to detect this change. A standard measurement signal corresponding to this pressure is converted and output.

Correct installation Usually, the damage of the high temperature melt pressure sensor is caused by its improper installation position, if the sensor is forcibly installed in too small holes or irregular holes, it is possible to cause the shock film of the sensor to be damaged by impact, choose the right tool to process the mounting hole, is conducive to controlling the size of the mounting hole, in addition, Suitable installation torque is conducive to the formation of a good seal, but if the installation torque is too high, it is easy to cause the slip of the high temperature melt pressure sensor, in order to prevent this phenomenon, it is usually applied on the thread part of the sensor before installation. 1. Correct installation method of pressure sensor: (1) Verify the frequency response value of the pressure sensor under ordinary atmospheric pressure and standard temperature conditions through the appropriate instrument. (2) Verify the correctness of the coding of the pressure sensor and the corresponding frequency response signal. 2. Determine the installation position In order to determine the number and specific installation position of the pressure sensor, it is necessary to consider each inflation section of the inflation network. (1) The pressure sensor must be installed along the cable, preferably at the cable junction. (2) Each cable is equipped with no less than 4 pressure sensors, and the two pressure sensors near the telephone office should not be as large as 200m apart. (3) Install one cable at the beginning and one cable at the end. (4) The branch points of each cable should be installed 1, if the two branch points are close to each other (less than 100 m), only 1 can be installed. (5) Cable laying method (overhead, underground) change place should be installed 1 (6) For cables without branches, because the cable program of the base line is consistent, the installation distance of the pressure sensor is not large 500m, and the total number of them is not less than 4. (7) In order to facilitate the determination of the pressure sensor fault point, in addition to the installation of the pressure sensor at the starting point, 150~200m from the starting point, but also install another 1, of course, in the design, must consider the economic and technical factors, in the place where the pressure sensor does not need to be installed, it should not be installed. Check size If the size of the mounting hole is not appropriate, the threaded part of the high temperature melt pressure sensor is vulnerable to wear during the installation process, which will not only affect the sealing performance of the equipment, but also make the sensor not fully play a role, and even may produce security risks. Only suitable mounting holes can avoid thread wear (thread industry standard 1/2-20UNF2B), and the mounting holes can usually be inspected with a mounting hole measuring instrument to make appropriate adjustments.

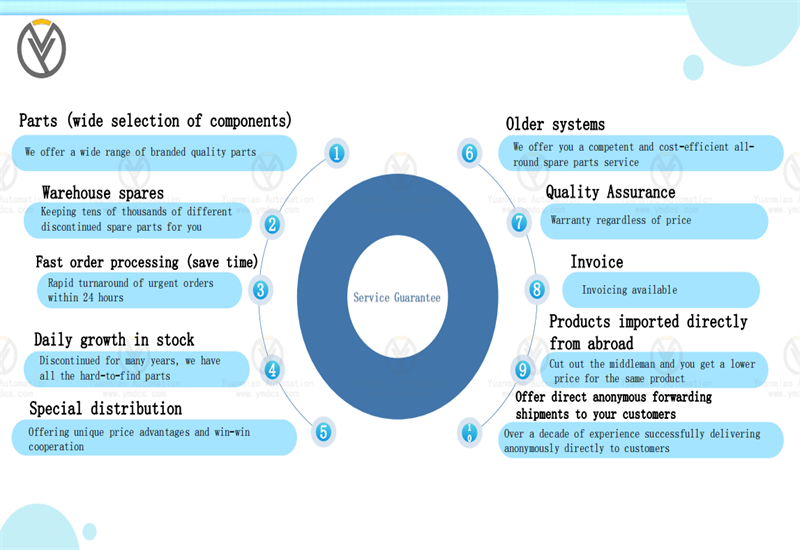

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

ABB Related Products

| 5SHX2645L0001 | 5SHY40L4511 |

| 5SHY5045L0020 | 5SHY50L5500 |

| 5SHY5055L0002 | 5SHY55L4500 |

| 5SHY3545L0001 | 5SHX26L4510 |

| 5SHY3545L0002 | 5SHX26L4520 |

| 5SHY3545L0003 | 5SHY35L4510 |

| 5SHY3545L0004 | 5SHY35L4511 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/ABB/