Description

Technical Specifications

| Control Power Input Range | 110 to 250 VDC, 100 to 240 VAC at 50/60 Hz |

| Ground Current Input Frequency | 20 to 100 Hz |

| Operating Range | -40°F to +140°F |

| Phase Current Input Conversion | True RMS, 1.04 ms/sample |

| Software | EnerVista 369 |

| Storage Range | -40°F to +176°F |

| Waveform Capture Length | 3 buffers containing 16 cycles of all current and voltage channels |

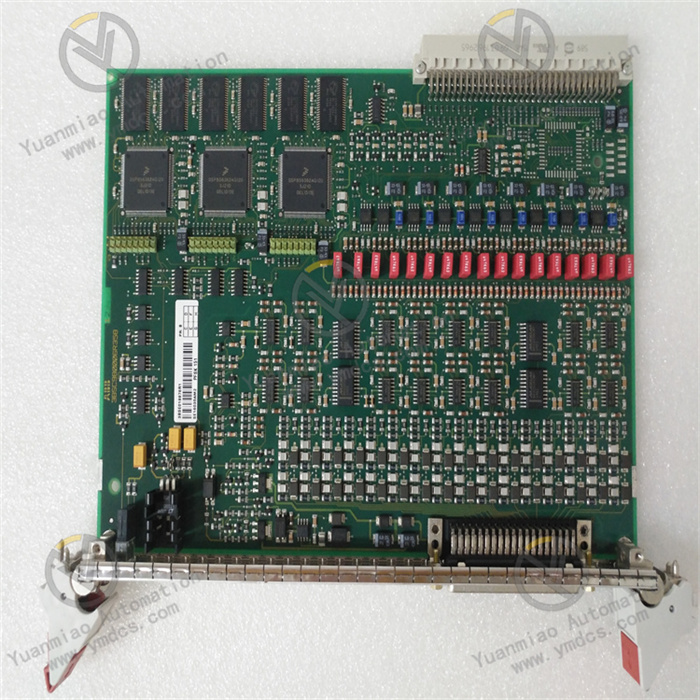

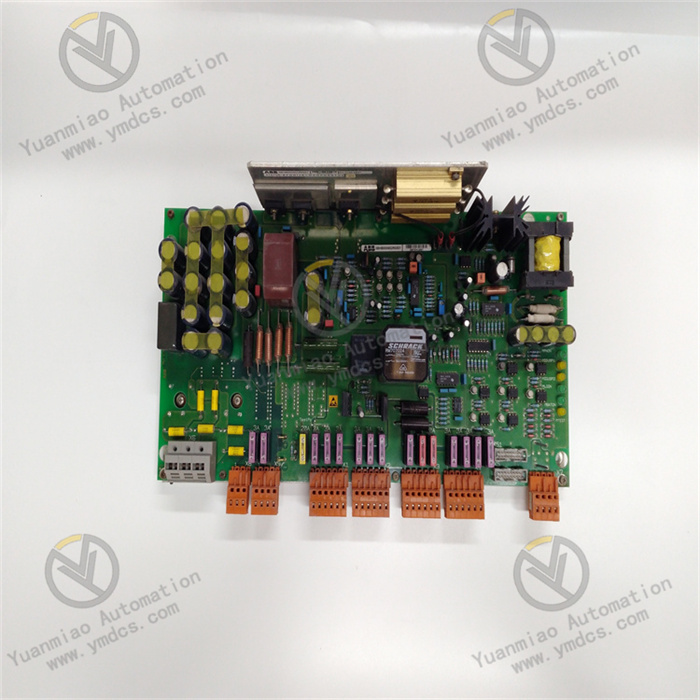

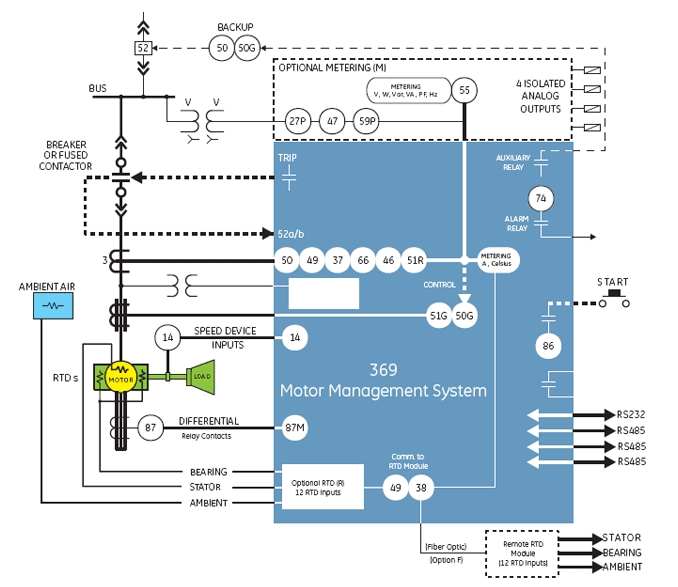

When you need designated protection and monitoring for your three-phase motors and mechanical systems, the 369 Motor Management Relay series is the ideal option. In providing the FlexCurve™ custom overflow curve, you gain the highest amount of motor protection in a single relay. The 369-HI-0-0-0-0 model also features a learning capability and is able to identify and accommodate individual motor parameters. This adaptation ability allows your system to perform in ways that are suitable to specific industrial applications. So if management versatility is something your equipment could use, this is the series for you. We offer a range of 369 Motor Management Relay systems at prices that accommodate a vast range of equipment budgets. The 369-HI-0-0-0-0 has an approximate height of 30 centimeters, an approximate length of 21 centimeters, and an approximate width of 11 centimeters. The unit is mounted in a DEMO metal carry case, which offers corrosion and flame retardent features. The 369-HI-0-0-0-0 has an in-case weight of 10 lbs and an out-of-case weight of approximately 8 lbs. Strong magnetic fields and high current conductors can damage the relay when in close proximity, so users should take care to mount the relay away from such hazards. The front of the relay is divided into roughly four sections, containing a liquid crystal display, a number of LED indicators, a keypad for manual setpoint entry and navigation, and an RS232 port to connect computers running General Electric's industry-leading software program, EnerVista 369.

The 369 relay, 269Plus Upgrade to 369, and 369 accessories are under last-time buy. Orders may be placed until 16th January 2024 and will be fulfilled based upon availability. As an alternative, please refer to 859. Designed for medium voltage motors, the 369 delivers simple setup configuration through the use of the Motor Settings Auto-Configurator, advanced graphical diagnostics with the Motor Health Report, comprehensive communications with multiple communication options and complete traceability of all setting changes with the Security Setting Change History Report, providing unparalleled motor protection for medium sized AC motors. Key Benefits • Enhanced Thermal Model • Complete Asset monitoring • Enhanced reporting • Reduce troubleshooting time and maintenance costs • Multiple communication protocols • Simplified programming with the EnerVista™ 369 Motor Settings Auto-Configurator • Optional Conformal coating • Field upgradeable settings and firmware • Suitable for hazardous locations • Installation flexibility • Safe and reliable motor re-start on “Down Hole” pump applications • User definable parameters and data size for DeviceNet polling • User definable parameters and data size for Profibus DPV1 cyclic data • Motor learned data on historical start characteristics

Applications

• Protection and control for medium sized AC motors

• “Down Hole” pump applications

• Suitable for applications involving Variable Frequency Drives

• Two Speed motor application

Key Features • Enhanced thermal model • Stall / Jam protection • Undervoltage, overvoltage • Underfrequency • Thermal overload • Undercurrent/current unbalance • Variable lockout time • Overtemperature 12 RTDs (R option) • Starts/hour, time between starts • Voltage Phase Reversal (M option) • Current based phase reversal • Undervoltage Auto-restart

Protection & Control The 369 is a digital motor protection system designed to protect and manage medium sized AC motors and their driven equipment. It contains a full range of selectively enabled, self contained protection and control elements as detailed in the Functional Block Diagram and Features table. Key Features • Seamless upgrade for existing Drawout Multilin 269 Motor Management Relays • Reduce system downtime utilizing the existing Multilin 269 Motor Management Relay drawout chassis • Reduce maintenance & operational costs - eliminates the need for mounting kits, re-work to existing cutouts and re-wiring of the chassis • Upgrade with ease using automated setting file conversion tool • Take advantage of newer, more advanced hardware and feature set

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

General Electric Related Products

| DS200RTBAG4A | DS200TCDAG2BBA |

| DS200RTBAG5A | DS200TCDAG2BCB |

| DS200SBCAG1A | DS200TCCAG1AHB |

| DS200SBCBG1A | DS200TCDAG1PR5 |

| DS200SDCCG5A | DS200TCCBG1ALC |

| DS200TCCBG1B | DS200TCDAH1BGD |

| DS200TCCBG2A | DS200TCDAH1BHD |

| DS200TCCBG3A | DS200TCCBG8BED |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/GE/