Description

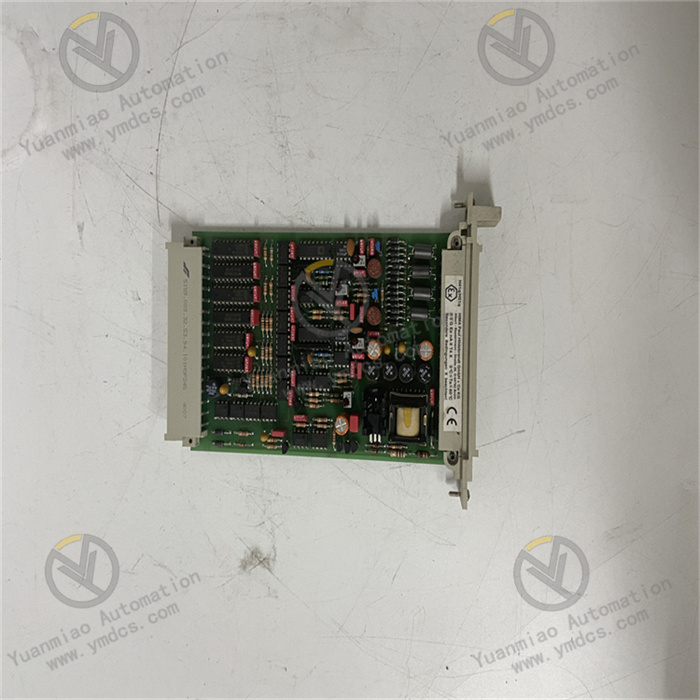

The GE / Bently Nevada 3500/42 Series Proximitor /Seismic Monitor Modules are four channel monitor that accepts input from Proximitor and Seismic Transducers and uses this input to drive alarms. The monitor can be programmed using the 3500 Rack Configuration Software to perform any of the following functions: Radial Vibration, Thrust Position, Eccentricity, Differential Expansion, Acceleration, and Velocity. The monitor can receive input from many types of transducers including the following Bently Nevada transducers: Proximitor Transducers, Acceleration, and Velocity. The primary purpose of the 3500/42 monitor is to provide 1) machinery protection by continuously comparing current machine vibration against configured alarm setpoints to drive alarms and, 2) essential machine vibration information to both operator and maintenance personnel. Alarm setpoints are configured using the 3500 Rack Configuration Software. Alarm setpoints can be configured for each active proportional value and danger setpoints can be configured for two of the active proportional values.

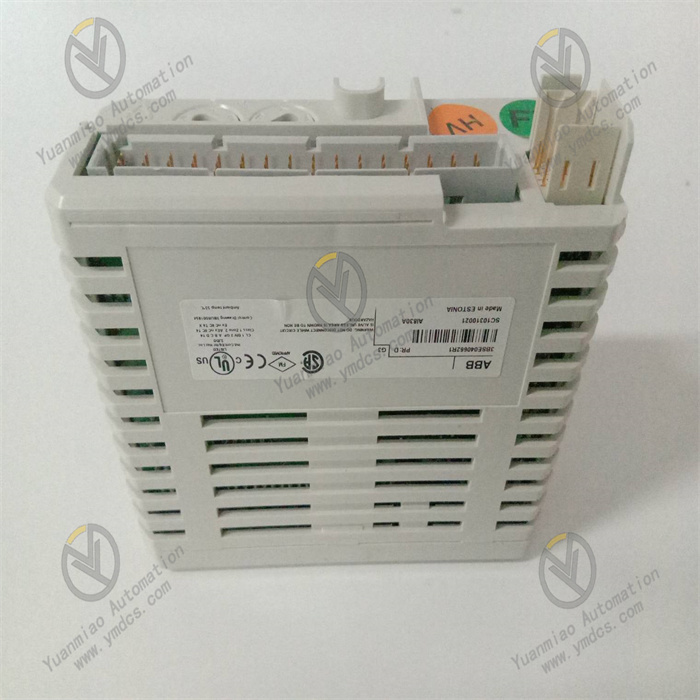

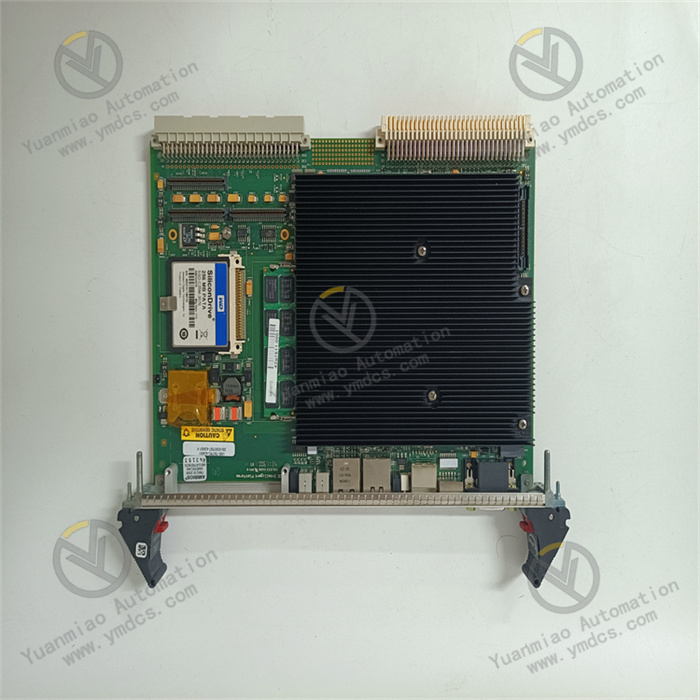

Manufacturer : Bently Nevada

Product No. : 3500/42-04-00

Product Type : Proximitor Seismic Monitor

Made in U.S.A

I/O Module Type : 04 = I/O Part Number : 135489-01, I/O Description : I/O Module with internal Barriers, internal terminations, 4 x Prox/Accel , Transducer Type : Prox/Accel on channels 1 through 4

Agency Approval : 00 = None

Weight : 0.91 Kg

Shipping Weight : 2 Kg

The 3500/42M Proximitor/Seismic Monitor is a 4-channel monitor that acceptsinput from proximity and seismic transducers, conditions the signal to providevarious vibrations and position measurements, and compares the conditionedsignals with user-programmable alarms. The user can program each channel ofthe 3500/42M using the 3500 Rack Configuration Software to perform any of thefollowing functions: • Radial Vibration • Thrust Position • Differential Expansion • Eccentricity • REBAM* • Acceleration • Velocity • Shaft Absolute • Circular Acceptance Region

Note: The monitor channels are programmed in pairs and can perform up to two of these functionsat a time. Channels 1 and 2 can perform one function, while channels 3 and 4 perform another (orthe same) function.

The primary purpose of the 3500/42M monitor is to provide: 1. Machinery protection by continuously comparing monitored parametersagainst configured alarm setpoints to drive alarms. 2. Essential machine information for both operations and maintenancepersonnel. Each channel, depending on configuration, typically conditions its input signal togenerate various parameters called “static values”. The user can configure Alertsetpoints for each active static value and Danger setpoints for any two of theactive static values.

Bently TSI3500 Series mechanical Protection System: 3500/15-05-05-00 127610-01 front 125840-01 back 3500/15-02-02-00 127610-01 Front 125840-01 back 3500/22-01-02-00 138607-01 front 146031-02 back 3500/25-01-01-00 149369-01 before 125800-01 after 3500/32-01-00 125712-01 Front 125720-01 back 3500/40-01-00 176449-01 front 125680-01 back 3500/40(140734-01 135489-04) 3500/42-01-00 176449-02 before 128229-01 after The eddy-current axis displacement sensor provides a simple and low-cost way to monitor the axis displacement of rotating machinery rotors directly with DCS and PLC interface. Real-time monitoring of shaft displacement of main engine and auxiliary equipment, such as steam turbine, compressor, fan, pump, motor, etc., can really protect such equipment. It is accurate in measurement, stable and reliable, and has strong anti-interference performance. ◆ Power supply: +24Vdc, maximum working current is less than 20mA. ◆ Input: HZ-891 series eddy current sensor probe. ◆ Spirit sensitivity: 8mA/mm. ◆ Accuracy: ≤1%. ◆ Transmission output: 4 ~ 20mA, maximum load resistance 500Ω. ◆ Output ripple: ≤20mV. ◆ Frequency response: 0 ~ 10KHz. ◆ Temperature bleaching: ≤0.1%℃. ◆ Overall size: 90mm(W)×35mm(L)×70mm(H). ◆ Installation size: base plate installation, 51mm×51mm, using four M4× 12GB29-76 bolts installation; Rail mounting, can be easily installed on the standard 35mm rail. ◆ Wiring mode: SpringLoc terminal is used, with automatic fastening function, and can be connected without installation tools, because it does not need bolts to be fixed, it will not loose. ◆ Operating temperature: -30℃ ~ 80℃.

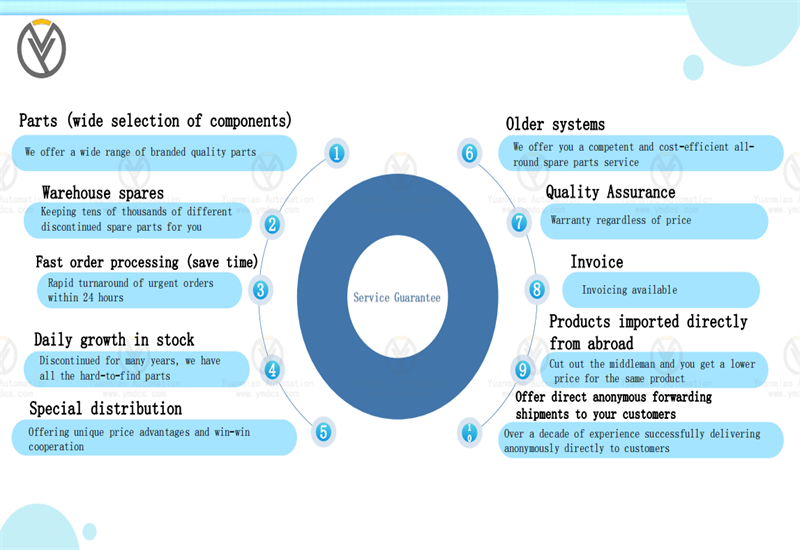

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

Bently Nevada Related Products

| 330101-00-60-10-02-00 | 330104-00-06-05-02-00 |

| 330101-00-60-05-02-05 | 330103-00-02-10-02-02 |

| 330101-00-50-10-02-00 | 330102-10-45-20-02-05 |

| 330101-00-48-10-02-05 | 330102-08-16-10-02-05 |

| 330101-00-40-10-02-00 | 330102-00-72-10-02-01 |

| 330101-00-30-10-02-05 | 330102-00-60-05-02-05 |

| 330101-00-28-10-12-05 | 330102-00-40-10-01-00 |

| 330101-00-28-10-11-00 | 330102-00-36-10-02-00 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/BentlyNevada/