Description

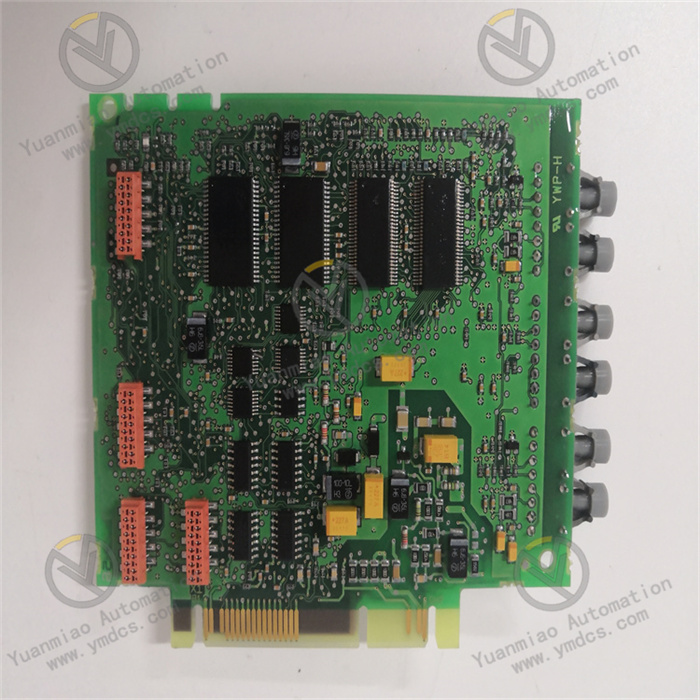

Part Number: 126599-01 Manufacturer: Bently Nevada Series: 3500 Product Type: Aero GT I/O Module (Internal Terminations) Availability: In Stock Dimensions: 241.3 mm x 24.4 mm x 99.1mm Weight: 0.45 kg Country of Origin: United States (USA) 126599-01 is an Aero GT I/O Module developed by Bently Nevada. It is a part of the 3500/44M Aeroderivitive GT Vibration Monitor system. The four-channel 3500/44M Aeroderivitive GT Vibration Monitor is an instrument created for use with aero-derivative gas turbines. It drives alerts by comparing observed parameters to predefined alarm setpoints to continuously monitor machines. It communicates crucial machine information to staff members who work in operations and maintenance. Aero GT I/O modules on the 3500/44M connect to Velomitor sensors and accelerometers using Bently Nevada interface modules. The monitor connects through the Prox/Velom I/O.

126599-01 Features

The 3500/44M Aeroderivitive GT Vibration Monitor is a four-channel instrument designed for aeroderivative gas turbine applications. It continuously monitors machinery by comparing monitored parameters to configured alarm setpoints to generate alarms.

The GT Vibration Monitor communicates critical machine information to both operations and maintenance personnel. The Aero GT I/O modules on the 3500/44M communicate with Velomitor sensors and accelerometers via Bently Nevada interface modules.

126599-01 Functional Description

You can configure the 3500/44M Aeroderivitive GT Vibration Monitor for the following filter options using the 3500 Rack Configuration Software:

Signal Integration

1X vibration tracking

Band-pass vibration

The 3500/44M Aeroderivitive GT Vibration Monitor accepts two separate Keyphasor signals as input, allowing each channel pair to use a different tracking filter. Multimode channels can be configured with up to eight sets of alarm parameters, including alert and danger setpoints and alarm time delays. Each set can be tailored to a particular machine mode. The monitor can switch to a specific set as the machine changes modes by using contacts on multimode I/O modules or software commands via a communications gateway.

Characteristics

Dimensions

Height x Width x Depth - 241.3 mm x 24.4 mm x 99.1mm

Weight

0.45 kg (1.0 lb)

Rack Space Requirements

1 full-height rear slot

The 3500/44M Aeroderivitive GT Vibration Monitor is a fourchannel instrument designed for aeroderivative gas turbineapplications. It: Continuously monitors machinery by comparingmonitored parameters against configured alarmsetpoints to drive alarms Communicates essential machine information for bothoperations and maintenance personnel The 3500/44M 's Aero GT I/O modules interface to Velomitorsensors and accelerometers through Bently Nevada interfacemodules. The monitor uses the Prox/Velom I/O to interface toour . Using the 3500 Rack Configuration Software, you canconfigure the 3500/44M Aeroderivitive GT Vibration Monitor forthe following filter options: Signal Integration 1X vibration tracking Band-pass vibration The 3500/44M Aeroderivitive GT Vibration Monitor acceptsinput from two separate Keyphasor signals, allowing eachchannel pair to use a different tracking filter. You can configure multimode channels to have up to eightsets of alarm parameters including alert and dangersetpoints and alarm time delays. Each set may be configuredfor a specific machine mode. As the machine changes modes, the monitor can switch to aspecific set using contacts on multimode I/O modules orsoftware commands through a communications gateway.

The eddy-current axis displacement sensor provides a simple and low-cost way to monitor the axis displacement of rotating machinery rotors directly with DCS and PLC interface. Real-time monitoring of shaft displacement of main engine and auxiliary equipment, such as steam turbine, compressor, fan, pump, motor, etc., can really protect such equipment. It is accurate in measurement, stable and reliable, and has strong anti-interference performance.

◆ Power supply: +24Vdc, maximum working current is less than 20mA.

◆ Input: HZ-891 series eddy current sensor probe.

◆ Spirit sensitivity: 8mA/mm.

◆ Accuracy: ≤1%.

◆ Transmission output: 4 ~ 20mA, maximum load resistance 500Ω.

◆ Output ripple: ≤20mV.

◆ Frequency response: 0 ~ 10KHz.

◆ Temperature bleaching: ≤0.1%℃.

◆ Overall size: 90mm(W)×35mm(L)×70mm(H).

◆ Installation size: base plate installation, 51mm×51mm, using four M4× 12GB29-76 bolts installation; Rail mounting, can be easily installed on the standard 35mm rail.

◆ Wiring mode: SpringLoc terminal is used, with automatic fastening function, and can be connected without installation tools, because it does not need bolts to be fixed, it will not loose.

◆ Operating temperature: -30℃ ~ 80℃.

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

Bently Nevada Related Products

| 330101-00-20-10-02-05 | 330101-49-80-05-02-00 |

| 330101-00-20-05-12-00 | 330101-26-40-10-02-00 |

| 330101-00-16-05-02-00 | 330101-09-51-10-02-05 |

| 330101-00-13-10-02-00 | 330101-05-26-10-02-05 |

| 330101-00-12-10-12-00 | 330101-02-12-10-02-00 |

| 330101-00-12-10-02-00 | 21000-02-36-00-120-03-02 |

| 21000-16-05-15-060-03-02 | 21000-00-00-00-250-03-02 |

| 21000-05-10-00-026-03-02 | 21000-00-00-00-120-03-02 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/BentlyNevada/