Description

Power system features ◆ Wide input voltage range ◆ The input voltage of the rectifier module is 120~290V (new equipment reaches 90 ~290V) ◆ High power factor, high efficiency ◆ Power factor of 99%, efficiency of 88% ◆ Non-destructive hot swap technology, easy maintenance (small improvement to solve big problems) ◆ Network design, unmanned and remote monitoring (a variety of background monitoring) ◆ Advanced battery management function (intelligent comprehensive management) ◆ Temperature compensation ◆ Load power-off (LLVD) and Battery Low Voltage Protection (BLVD) ◆ Charging current limit, timed balanced charging ◆ Battery capacity calculation, online battery testing System principle ◆ AC power enters the rectification part through the AC distribution branch; The +24V DC power obtained by the rectifier modules is connected to the DC power distribution and provided to the communication equipment in multiple channels. ◆ Under normal circumstances, the system runs in parallel floating charging state, that is, the rectifier module, the load, the battery work in parallel, the rectifier module in addition to supply power to the communication equipment, but also provide floating charging flow for the battery. ◆ When the mains power is off, the rectifier module stops working, and the battery supplies power to the equipment to maintain the normal operation of the equipment. ◆ After the mains is restored, the rectifier module supplies power to the equipment again, and charges the battery to supplement the consumed electricity. ◆ The monitoring module adopts the centralized monitoring method to manage AC power distribution and DC power distribution, and receives the operation information of the rectifier module through the RS485 interface and carries out the corresponding control. ◆ The monitoring module can also be connected to the local computer through RS485, RS232, and can be connected to the monitoring center through the Modem or other transmission resources (such as official channels, etc.) to realize the centralized monitoring network of the power system.

Benefits

Decreases capital equipment costs

Full system modularity: The Traditional I/O subsystem wasdesigned with your investment in mind. All components arefully modular and may be installable under power. You addI/O interface carriers and I/O interfaces in groups of 4, 8, 16,or 32 channels as you need them. The modular design enablesyou to purchase the exact amount of I/O cards, 8-wide or4-wide carriers, power/ controllers, and 2-wide carriers youneed and add more DeltaV I/O as your system grows. Reduced system footprint: The DeltaV system’s state-of-theart form factor design of the I/O components enables you tomount the I/O interface carrier in a junction box in the fieldso you significantly reduce the footprint of your equipmentand increase valuable control room space for other uses. Installation: Save on wiring expenses by installing ClassicInstrumentation in the field, near the actual field devices. Mounting the controller with the I/O further reduces yourwiring expenditures by eliminating the need for long runsof multi-cores. The integrated design of the Traditional I/Osubsystem can eliminate the need for marshalling panels. This saves you even more in your total capital costs. The provision of in-line fuses and bussed power saveson installation costs compared with external fuses andpower distribution.

Decreases installation time and expense Plug-and-play installation saves money: All TraditionalI/O components plug into the I/O interface carrier. You caninstall the I/O interface carriers to manage anticipated growthand postpone the I/O interfaces until you’re ready to installyour additional field devices Phased installation saves time: As soon as you mount theI/O interface carrier, you’re ready to begin installing the fielddevices. I/O terminal blocks plug directly onto the I/O interfacecarrier. There is no need to have the I/O cards installed. Keys: Traditional I/O interfaces and terminal blocks haveI/O function keys. These keys ensure that the correct I/Ocard is always plugged into the corresponding terminal block. It’s incredibly easy to use and gives you time to do more. This design enables you to initially install Traditional I/Oquickly and efficiently. When you need to replace an I/O card,the function key design ensures that you will always installit correctly. This keying system provides a safety measureby preventing the wrong I/O interface’s being installed.

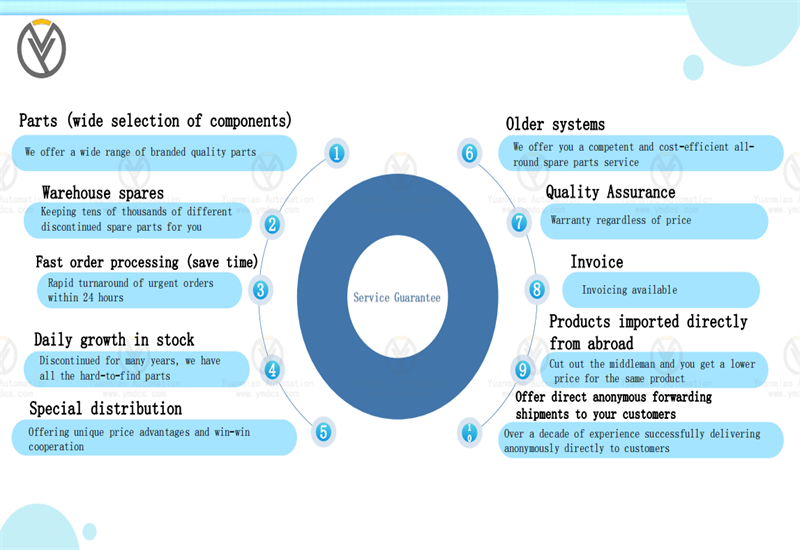

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

Emerson Related Products

| 1C31181G01 | 5X00300G01 |

| 1C31181G03 | 5X00327G01 |

| 1C31181G04 | 5X00332G01 |

| 1C31182G02 | 5X00333G01 |

| 1C31183G01 | 5X00354G01 |

| 1C31189G03 | 5X00355G01 |

| 1C31191G01 | 5X00356G01 |

| 1C31194G04 | 5X00357G01 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/EMERSON/