Description

GE DS200FCGDH1B

The GE DS200FCGDH1B is a high-performance excitation control module designed for large-scale industrial drive systems. As a core excitation regulation component of the GE Speedtronic Mark VIe series gas turbine control system, it is positioned as a "dedicated control terminal for excitation systems of heavy-duty gas turbines/steam turbines". Its core function is to receive excitation commands from the unit control system, control the output of the excitation power unit through precise pulse modulation technology, and adjust the excitation current and voltage of the generator. Meanwhile, it is equipped with functions such as real-time monitoring of excitation parameters, fault diagnosis, fault-tolerant control, and high-speed communication with the host control system, providing core excitation regulation support for the stable operation of large-scale generator sets in fields such as electric power, petrochemicals, and metallurgy.

With high-precision excitation regulation, fast dynamic response, strong fault-tolerance capability, and comprehensive protection mechanisms, this module is well-adapted to the excitation control requirements of large-scale units during start-stop, load fluctuations, and fault conditions. It serves as a key core unit for the GE Speedtronic Mark VIe series control system to achieve "precise excitation regulation - stable unit power generation - fault safety fault tolerance".

Its application scenarios accurately match the excitation control needs of large-scale industrial drive and power generation systems:

- In the electric power field, as the core of excitation control for large-scale gas turbine generator sets, it is deployed in the unit control cabinet. It receives excitation commands from the Mark VIe controller, adjusts the generator rotor excitation current, and achieves a voltage regulation accuracy of ±0.2%, ensuring the voltage stability of the unit during grid-connected operation. When the load changes by ±10%, the voltage recovery time is ≤100ms.

- In the petrochemical field, it is used in the excitation system of steam turbine generator sets in captive power plants, adapting to multi-unit parallel operation scenarios. It realizes multi-module collaborative control through the CANopen bus, with an excitation regulation response speed of ≤50μs, ensuring balanced distribution of reactive power among parallel units with an imbalance of ≤2%.

- In the metallurgical field, it provides excitation control for the synchronous motor of large blast furnace blowers. The module outputs precise pulse signals to drive the thyristor power unit, achieving an excitation current regulation accuracy of ±0.5%, ensuring stable motor speed under different load conditions with a speed fluctuation of ≤0.1%.

As a dedicated excitation control module of the Mark VIe series, it supports seamless adaptation with in-series CPU modules (such as IC698CPU310), communication modules (such as IC698ETM001), and HMI (Human-Machine Interface). Through the GE CIMPLICITY HMI configuration software, it realizes excitation parameter configuration, real-time monitoring, and fault early warning, meeting the strict excitation control requirements of "high precision, high response, and high reliability" for large-scale industrial units.

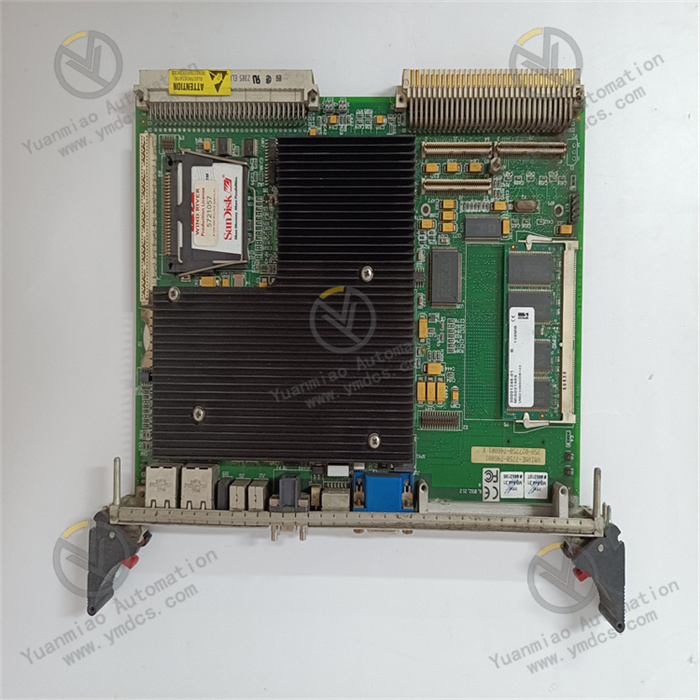

In terms of hardware architecture and system compatibility, the DS200FCGDH1B adopts a hardware architecture of "dual-core redundant control + high-precision signal conditioning + high-speed pulse output". Its core consists of two 32-bit industrial-grade MCUs, an excitation parameter sampling circuit, a PWM pulse modulation unit, a fault diagnosis module, and a multi-protocol communication interface.

The module is equipped with 1 excitation voltage/current sampling interface (supporting 0-10V analog input or 4-20mA current input), 6 thyristor trigger pulse output interfaces (adapting to three-phase fully controlled bridge power units), and 2 redundant communication interfaces (supporting both EtherNet/IP and CANopen protocols), with a maximum communication rate of 100Mbps to ensure real-time transmission of excitation commands and status feedback. It has a built-in high-precision AD conversion chip with a sampling accuracy of 16 bits and a sampling frequency of 1kHz, which can real-time collect key parameters such as generator stator voltage, rotor current, and excitation circuit temperature.

In terms of regulation performance, the module adopts a "PID + fuzzy control" composite algorithm and supports three excitation control modes: constant voltage, constant current, and constant power factor, which can be flexibly switched through configuration software. In the constant voltage control mode, the voltage regulation accuracy is ±0.2% with a dynamic response time of ≤50μs; in the constant current mode, the current regulation accuracy is ±0.5%, meeting the control requirements of different operating conditions.

In terms of redundancy design, the module supports dual-module hot standby redundancy configuration. It realizes real-time status synchronization between the main and standby modules through a redundant communication bus. When the main module fails, the standby module switches seamlessly within 10ms, with no fluctuation in excitation parameters during the switching process, ensuring the continuous operation of the unit's excitation system.

In terms of protection performance, it adopts a dual mechanism of "hardware fast protection + software logic protection". At the hardware level, it integrates overcurrent protection (triggered when the excitation current exceeds 120% of the rated value), overvoltage protection (triggered when the excitation voltage exceeds 110% of the rated value), overtemperature protection (triggered when the module temperature exceeds 85℃), and pulse loss protection. At the software level, it realizes functions such as loss-of-excitation protection, over-excitation limitation, and under-excitation limitation for the excitation system through a composite control algorithm. When a fault is detected, it immediately cuts off the pulse output and sends a fault signal to the host.

Relying on an industrial-grade reinforced design, the module uses wide-temperature-tolerant components (-25℃~75℃), corrosion-resistant gold-plated terminals, and an enhanced heat dissipation structure (aluminum heat sink + temperature-controlled fan). It complies with the IEC 60068-2 series of environmental adaptability standards and can operate stably in industrial sites with high temperature, high humidity, and strong electromagnetic interference.

The DS200FCGDH1B adopts a "PID + fuzzy control" composite regulation algorithm, breaking through the limitations of traditional single PID control and achieving precise excitation regulation under different operating conditions.

In the constant voltage control mode, the algorithm real-time collects the generator stator voltage signal and dynamically optimizes the PID parameters in combination with fuzzy control, achieving a voltage regulation accuracy of ±0.2%—far higher than the industry's conventional standard of ±0.5%. When the unit load changes by ±10%, the algorithm can respond within 50μs and quickly adjust the excitation current by modifying the pulse trigger angle, restoring the stator voltage to the rated value within 100ms and effectively suppressing voltage fluctuations.

In the constant current control mode, it real-time monitors the rotor excitation current through a high-precision current sampling circuit and adopts current closed-loop control logic, achieving a current regulation accuracy of ±0.5%, which meets the excitation requirements of scenarios such as synchronous motor startup and speed regulation.

In the constant power factor control mode, the module real-time collects the active power and reactive power signals of the generator, automatically adjusts the excitation current through power factor closed-loop calculation, and stabilizes the power factor at a set value (adjustable between 0.8 and 1.0), reducing the reactive power loss of the power grid.

The three control modes can be quickly switched through configuration software or external control signals without modifying hardware wiring, adapting to the full operating conditions of the generator set, including startup, grid connection, and load regulation. For example, when a large-scale gas turbine generator set is operating in grid-connected mode, the module works in the constant power factor mode, stabilizing the power factor at 0.95 and ensuring the unit's reactive power output deviation is ≤2%, effectively improving the power supply quality of the power grid.

The module supports 1+1 dual-module hot standby redundancy configuration and realizes real-time status synchronization between the main and standby modules through a redundant communication bus (CANopen), building a highly reliable excitation control system.

During normal operation, the main module undertakes the tasks of excitation regulation and pulse output, while the standby module real-time collects the excitation parameters (trigger angle, output pulse frequency, sampling data, etc.) of the main module and its own status data, and realizes data synchronization through the redundant bus with a synchronization delay of ≤1ms. The standby module is in a "hot standby" state, not participating in actual control but capable of taking over control immediately.

When the main module fails (such as abnormal pulse output, sampling circuit failure, communication interruption, or module overtemperature), the standby module detects the fault within 10ms through the fault diagnosis mechanism and automatically switches to the main control mode, immediately taking over the excitation regulation task. During the switching process, there is no fluctuation in key parameters such as the pulse trigger angle and excitation current, ensuring the continuous operation of the generator's excitation system and avoiding unit shutdown caused by excitation interruption.

The redundant system supports two modes: "manual switching" and "automatic switching". Manual switching can be triggered through the HMI interface for daily maintenance or fault simulation testing; in the automatic switching mode, the system can intelligently determine whether to switch based on the fault level, improving the flexibility of operation and maintenance. For example, in a petrochemical captive power plant, the DS200FCGDH1B with dual-module redundancy configuration provides excitation control for the steam turbine generator. When the main module fails due to communication interference, the standby module completes the switch within 8ms, with an excitation current fluctuation of ≤1%, and the unit does not shut down, ensuring continuous power supply for chemical production.

The module integrates a triple protection mechanism of "hardware fast protection + software logic protection + fault diagnosis", covering all-scenario fault risks of the excitation system and comprehensively improving operational safety.

At the hardware protection level, it has a built-in fast fuse, overvoltage suppression diode, and temperature relay. When the excitation current exceeds 120% of the rated value, the fast fuse blows within 50μs to cut off the pulse output circuit; when the excitation voltage exceeds 110% of the rated value, the overvoltage suppression diode turns on instantly to clamp the voltage within a safe range; when the internal temperature of the module exceeds 85℃, the temperature relay triggers, cutting off the module power supply and sending an alarm signal.

At the software protection level, multiple logic protections are implemented through a composite control algorithm: loss-of-excitation protection can detect whether the rotor excitation current is below the threshold and immediately trigger the emergency excitation circuit when loss of excitation is detected; over-excitation limitation monitors the product of excitation current and time to avoid rotor overheating caused by long-term over-excitation; under-excitation limitation prevents stability issues caused by excessive unit leading-phase operation.

At the fault diagnosis level, the module has a full-parameter real-time monitoring function with a sampling frequency of 1kHz, which can monitor more than 20 parameters such as pulse output status, excitation voltage/current, module temperature, and communication status. It supports channel-level fault diagnosis: when an abnormal pulse output of a channel or a sampling channel fault is detected, it immediately locates the faulty channel and issues an alarm, and automatically switches to the standby channel (if configured). It also has a fault memory function that can store the latest 500 fault records, including fault type, occurrence time, and excitation parameters at the time of the fault. Fault records can be read through the HMI or configuration software, facilitating maintenance personnel to trace the cause of faults. For example, in the excitation system of a metallurgical blast furnace blower motor, when the trigger pulse of a thyristor channel is lost, the module detects the fault within 1ms, immediately switches to the standby pulse channel, and displays the "CH03 Pulse Loss" alarm on the HMI interface. Maintenance personnel quickly replace the faulty component based on the fault record, reducing the fault handling time by 60%.

The module adopts an anti-interference design system of "multiple electromagnetic shielding + signal isolation + power filtering", enabling stable operation in the strong interference environment of large-scale industrial sites.

In terms of electromagnetic shielding, the module housing is made of high-strength galvanized steel, and a 0.5mm-thick copper foil shielding layer is laid on key internal circuits (such as the PWM modulation unit and communication interface circuit). The housing and shielding layer form a complete electromagnetic shielding network through multi-point grounding, with a shielding effectiveness of ≥80dB, complying with the IEC 61000-4-3 standard for radio frequency radiation immunity (20V/m), which can effectively resist strong electromagnetic radiation interference generated by equipment such as generators and frequency converters.

In terms of signal isolation, it adopts a dual isolation mechanism of "channel-level photoelectric isolation + bus-level magnetic isolation". The isolation voltage between the sampling input channel and the internal control circuit is ≥2kVrms, between the pulse output channel and the control circuit is ≥3kVrms, and between the communication interface and the internal circuit is ≥2.5kVrms. This effectively blocks common-mode interference and differential-mode interference, avoiding the impact of on-site high-voltage signals on the module's control circuit.

In terms of power filtering, the module has a built-in two-stage EMC filter. The input-side filter can filter out 50/60Hz fundamental interference and high-frequency harmonics in the power grid, and the output-side filter suppresses interference generated by pulse signals, with a power supply ripple rejection ratio of ≥50dB, ensuring stable power supply for the internal control circuit.

In terms of environmental adaptability, the module uses wide-temperature-tolerant components (-25℃~75℃), with core chips selected from industrial-grade wide-temperature models. It is equipped with an intelligent heat dissipation system (aluminum heat sink + temperature-controlled fan): the fan starts automatically when the module temperature exceeds 60℃ and stops when the temperature is below 50℃, ensuring heat dissipation efficiency while reducing energy consumption. Its anti-vibration performance meets the 5g acceleration requirement of the IEC 60068-2-6 standard, allowing direct installation in control cabinets close to generators. It has a protection level of IP20 and is equipped with a dust-proof cover to effectively prevent dust intrusion; if equipped with a custom protective enclosure, the protection level can be upgraded to IP65, adapting to harsh environments such as outdoors and high humidity. In industrial on-site tests, the module still operates normally under ±4kV electrical fast transient burst interference, with an excitation parameter fluctuation of ≤0.3%, fully verifying its strong anti-interference performance.

![]()