Description

The 369-HI-R-M-0-0-H-E weighs approximately ten pounds and is mounted in a DEMO metal carry case, which offers some protection against operation environment factors. The case is flame and corrosion retardant and should be mounted away from strong magnetic fields or high current conductors, which could cause damage to the relay over time.

369-HI-R-M-0-0-H-E Technical Specifications

| Communications | non-isolated RS232 port, RS485 port |

| Control Power Input Range | 110 to 250 VDC, 100 to 240 VAC at 50/60 Hz |

| Differential Switch Time Delay | <200 ms |

| Dimensions | approx : 29.6cm H x 10.7cm W x 20.5cm L |

| Event Record Triggers | power fail, alarms, self test, inhibit, trip, waveform capture |

| Operating Range | -40°C (-40°F) to +60°C (140°F) |

| Storage Range | -40°C (-40°F) to +80°C (176°F) |

General Electric Multilin’s 369-HI-R-M-0-0-H-E is a Motor Protection and Management Relay designed to protect medium motors and their accompanying parts. The motor is able to ‘learn’ and adapt to each individual motor’s needs, configuring itself more specifically to the system it is assigned to. The 369 relay can monitor and document total accumulated mega-watt hours, varieties of motor trips, total number of motor trips, number of motor starts, and total hours running. Besides being a useful source of general information, the data can assist in diagnosing motor faults and planning future maintenance. The 369-HI-R-M-0-0-H-E offers users a variety of inputs and outputs to accomplish their motor management needs. The Speed Switch Input allows the use of external speed devices, which can enable a normal start to be easily distinguished from a locked rotor condition, shutting down the relay when conditions are poor. Other inputs include Waveform Capture and Digital Counters. This particular model includes the enhanced diagnostic and faceplate option along with the conformal coating. The enhanced faceplate offers a cleaner design and is included with the diagnostic option. The conformal coating is a thin, polymeric film that protects the relay from variable temperatures, corrosive materials, dust, and humidity. The 369-HI-R-M-0-0-H-E weighs approximately ten pounds and is mounted in a DEMO metal carry case, which offers some protection against operation environment factors. The case is flame and corrosion retardant and should be mounted away from strong magnetic fields or high current conductors, which could cause damage to the relay over time.

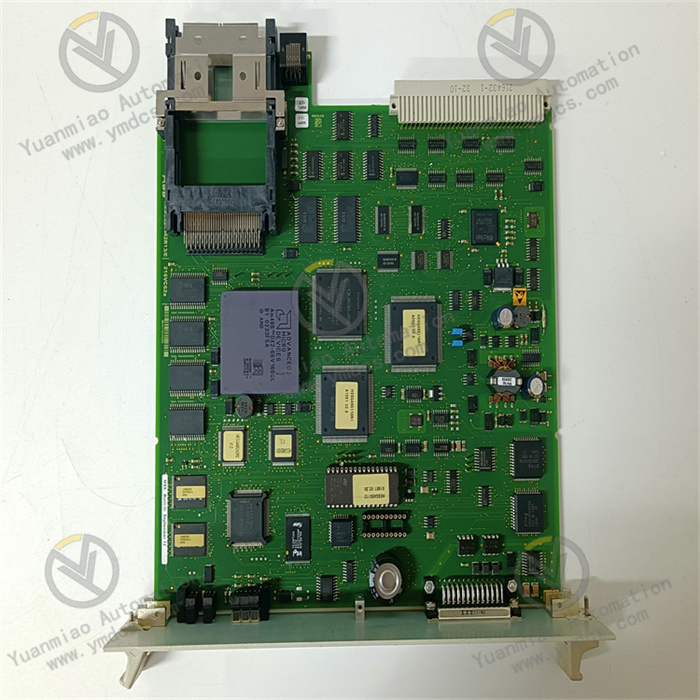

The communication module of the programmable controller is equivalent to the network interface in the local area network. The communication module data bus is connected to the PLC host, and the communication protocol is realized by hardware and software. The communication module of the programmable controller is generally provided with multiple interfaces, which can be selected through the selection switch on the communication module to realize the communication with other programmable controllers, intelligent control devices or computers. The input module is used to receive and collect input signals. There are two types of input signals: one is the switch input signal, which is provided by the button switch, the travel switch, the digital dip switch, the proximity switch, the photoelectric switch, the pressure relay, etc. The other is a continuously varying analog input signal sent by a potentiometer, thermoelectric meter, tonometer, motor, and various transmitters. The input module also needs to convert these different level signals into digital signals that the CPU can receive and process. The function of the output module is to receive the digital signal processed by the central processor and convert it into a signal that can be received by the field executive parts for controlling contactors, solenoid valves, regulating valves, speed regulating devices, etc. Another type of load control is the indicator light, digital display and alarm device.

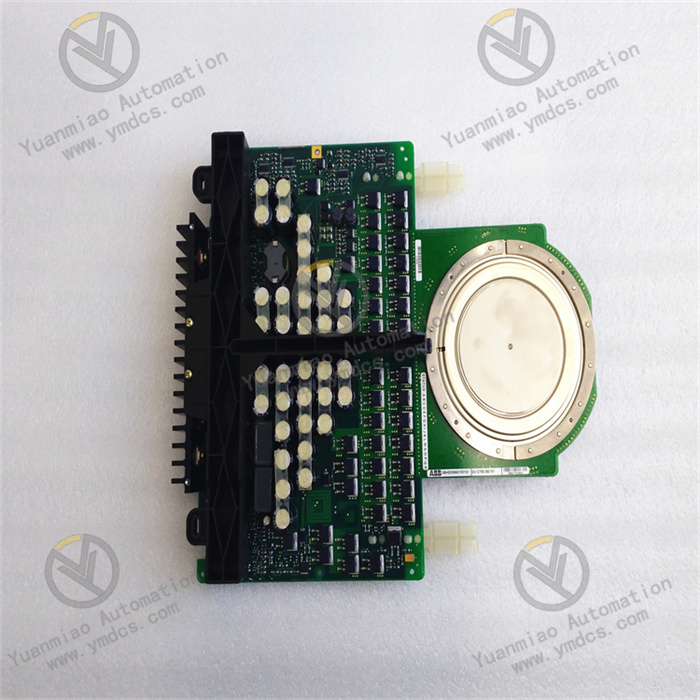

The role of the output module The function of PLC output module is to amplify the power of the output signal. The PLC signal is expressed by the level, so that it does not distort in the process of being read out, it needs to have a certain reserve energy or a certain signal power. The function of the output module is actually a power amplifier. The output module is what drives the external load. Common PLC output devices are transistors, thyristors, relays. The PLC input module is used to receive the various parameters of the production process. (start stop) The PLC output module is used to send out the information obtained after the operation of the programmable controller, and complete all kinds of control of the industrial site through the actuator outside the machine. (Execution results with output) 1. Have good anti-interference ability. 2. It can meet the matching requirements of various signals in industrial sites. PLC digital output type plc switching output types are roughly divided into three types, relay output type, transistor output type and thyristor output type. R-relay; t-transistor Relay output AC DC can be, the transistor common 5vdc and 24vdc output, thyristor is relatively rare, only special output models have. Considering the type of output module selected, usually the relay output module has low price, wide voltage range (can be connected to the mains), large load capacity, small on-voltage drop, strong ability to withstand instantaneous voltage and overcurrent, but short life, long response time, slow action speed and so on. Transistor output (can be divided into PNP, NPN type) has the advantage of fast on-off speed (pulse output, suitable for high frequency), generally about 0.2ms; Long life; The disadvantage is low working voltage (can not be connected to the mains); The load capacity is weak, about 300mA. Thyristor output module is suitable for DC load, frequent switching, fast reaction speed, long life, low inductive power factor load, but the price is more expensive, the overload capacity is poor.

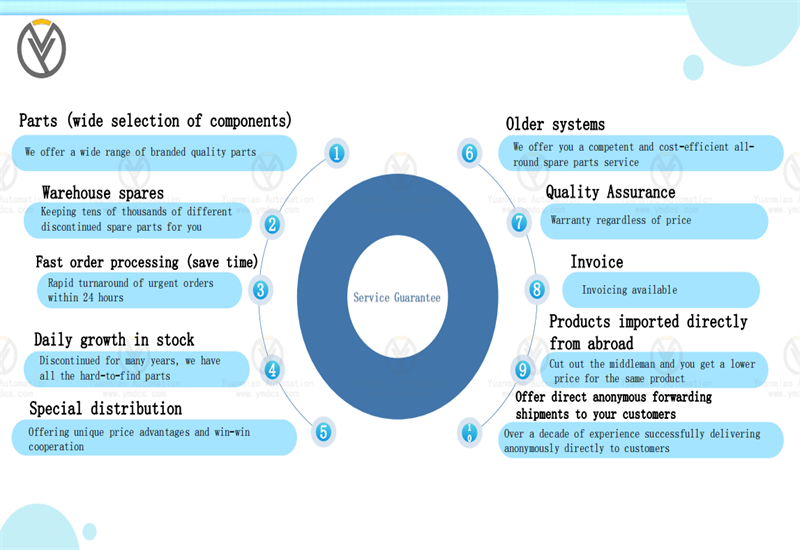

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/GE/