Description

Redundant system configuration (1) : Install software ◆ Install RSLogix5000/Studio5000 software, pay attention to the version, RSLinx Classic software will be automatically installed. ◆ If use ControlNet architecture, install RSNetWorx for ControlNet software. ◆ Install redundant firmware packages, ControlFlash V14 or above or ControlFlash Plus tools ◆ Install the redundant configuration tool RMCT (2) : Install hardware ◆ Install the power module, processor, communication module, and redundant module into the rack. ◆ In two racks, install the same module in the same slot. It is recommended that redundant modules be placed close to the processor. ◆ ControlNet Communication module nodes are set through DIP switches. ◆ Optical fiber connection for redundant modules, no sequence requirement for optical ports. ◆ Connect the power supply to the power module. (3) Establish a connection with the computer ◆ Power on two racks. ◆ Connect the processor to the computer using a USB cable, and you can see the rack and all the modules on the rack in RSLinx Classic. ◆ Set IP address for Ethernet module in RSLinx Classic, changed to static. You can also use BOOTP-DHCP to directly set the IP address for the Ethernet module. ◆ The IP addresses, subnet masks, and gateways of the corresponding Ethernet modules must be the same. ◆ Set up Ethernet/IP driver in RSLinx Classic, you can see the rack and all the modules on the rack through Ethernet. (4) : Firmware refresh ◆ Use the ControlFlash or ControlFlash Plus tools to refresh the modules in the rack. ◆ The version to be updated depends on the Release Notes of the firmware package. ◆ Brush on two racks respectively. ◆ The processor key switch is in REM mode. (5) : Network configuration Ethernet/IP ◆ Star topology, the Ethernet module is connected to the switch. ◆ Ring topology: Set the ring network manager, connect all DLR ring network nodes, view the ring network status in RSLinx Classic. ◆ Set Ethernet routes in RSLinx Classic (6) : Redundant module configuration ◆ Basic use No redundant modules are required. ◆ You are advised to use RMCT to set the redundant module time.

servo motor (servo motor) refers to the engine that controls the operation of mechanical components in the servo system, which is a supplementary motor indirect transmission device. The servo motor can control the speed, the position accuracy is very accurate, and the voltage signal can be converted into torque and speed to drive the control object. Servo motor rotor speed is controlled by the input signal, and can react quickly, in the automatic control system, used as an executive component, and has the characteristics of small electromechanical time constant, high linearity, starting voltage, etc., can convert the received electrical signal into the angular displacement or angular speed output on the motor shaft. Divided into DC and AC servomotor two categories, its main feature is that when the signal voltage is zero, there is no rotation phenomenon, and the speed decreases with the increase of torque. Working principle and application of servo motor A servo mechanism is an automatic control system that enables the controlled output of an object, such as its position, orientation, and state, to follow any change in the input target (or given value). The servo mainly depends on the pulse to position, basically can be understood in this way, the servo motor receives a pulse, it will rotate the corresponding Angle of a pulse, so as to achieve displacement, because the servo motor itself has the function of pulse, so each rotation Angle of the servo motor, will emit the corresponding number of pulses, so that the pulse accepted by the servo motor echoes. Or closed loop, so that the system will know how many pulses are sent to the servo motor, and how many pulses are received back, so that the rotation of the motor can be controlled very accurately, so as to achieve accurate positioning, which can reach 0.001mm.

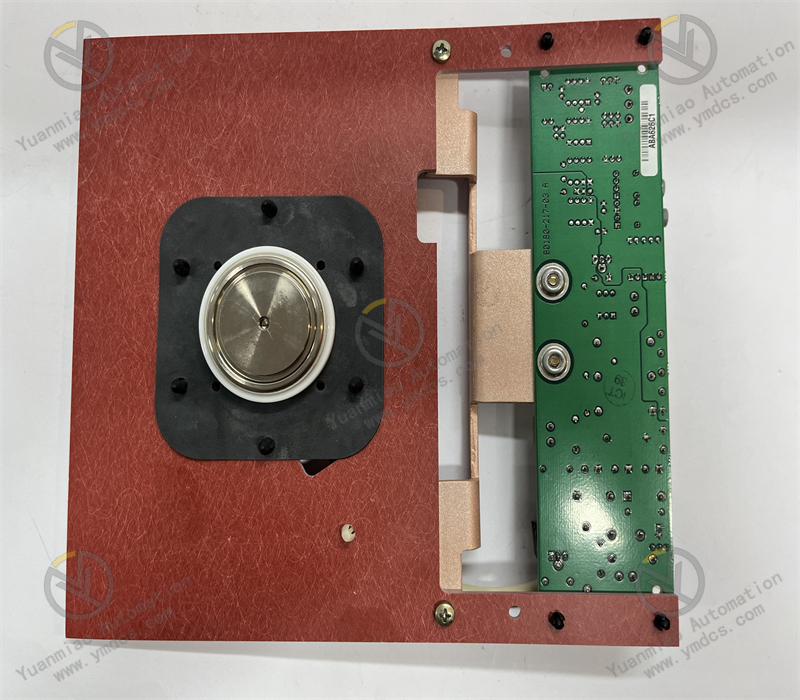

Dc servo motors are divided into brushed and brushless motors. Brush motor has low cost, simple structure, large starting torque, wide speed regulation range, easy control, and needs maintenance, but the maintenance is not convenient (change the carbon brush), electromagnetic interference, and the environment is required. Therefore, it can be used in cost-sensitive general industrial and civil applications.

Brushless motor small size, light weight, large output, fast response, high speed, small inertia, smooth rotation, torque stability. The control is complex, easy to achieve intelligence, its electronic commutation mode is flexible, can be square wave commutation or sine wave commutation. The motor is maintenance-free, high efficiency, low operating temperature, small electromagnetic radiation, long life, and can be used in a variety of environments.

The company focuses on DCS, PLC, robot, large servo four systems

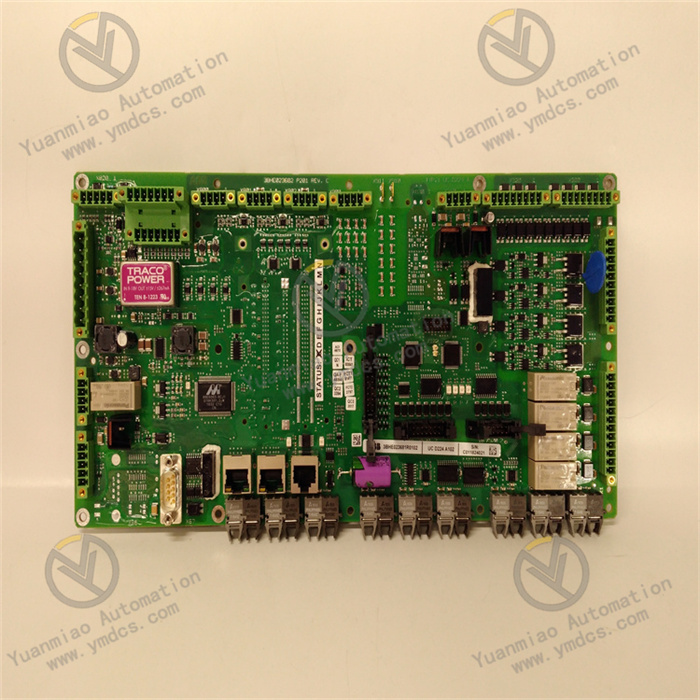

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Allen-Bradley/