Description

servo drives (servo drives), also known as "servo controller", "servo amplifier", is a controller used to control the servo motor, its role is similar to the frequency converter acting on the ordinary AC motor, is a part of the servo system, mainly used in high-precision positioning system. Generally, the servo motor is controlled through three ways of position, speed and torque to achieve high-precision transmission system positioning, which is a high-end product of transmission technology. Servo drive is an important part of modern motion control, which is widely used in industrial robots and CNC machining centers and other automation equipment. In particular, the servo drive used to control AC permanent magnet synchronous motor has become a research hotspot at home and abroad. The current, speed and position three closed-loop control algorithms based on vector control are widely used in the design of AC servo drivers. Whether the speed closed-loop design in this algorithm is reasonable or not plays a key role in the whole servo control system, especially in the performance of speed control. In the speed closed loop of servo drive, the real-time speed measurement accuracy of motor rotor is very important to improve the dynamic and static characteristics of speed control of speed ring. In order to find the balance between measurement accuracy and system cost, incremental photoelectric encoder is generally used as the speed measurement sensor, and its corresponding common speed measurement method is M/T speed measurement. Although M/T velocity measurement method has a certain measurement accuracy and a wide measurement range, but this method has its inherent defects, including: 1) the speed measurement cycle must detect at least one complete code pulse, limiting the minimum measurable speed; 2) The timer switches of the two control systems used for speed measurement are difficult to maintain strict synchronization, and the accuracy of speed measurement cannot be guaranteed in the measurement occasions with large speed changes. Therefore, it is difficult to improve the performance of servo drive speed following and control by using the traditional speed loop design method.

Working principle

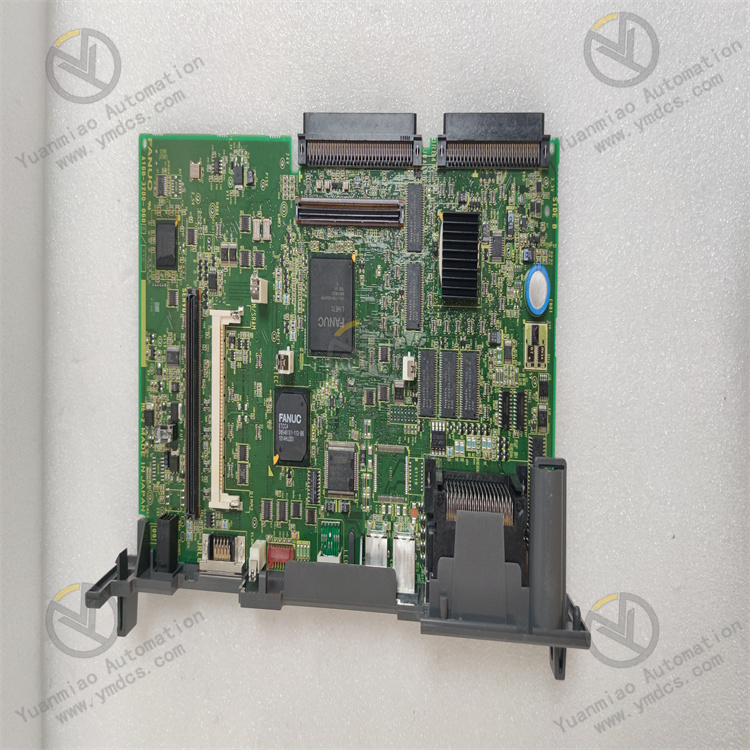

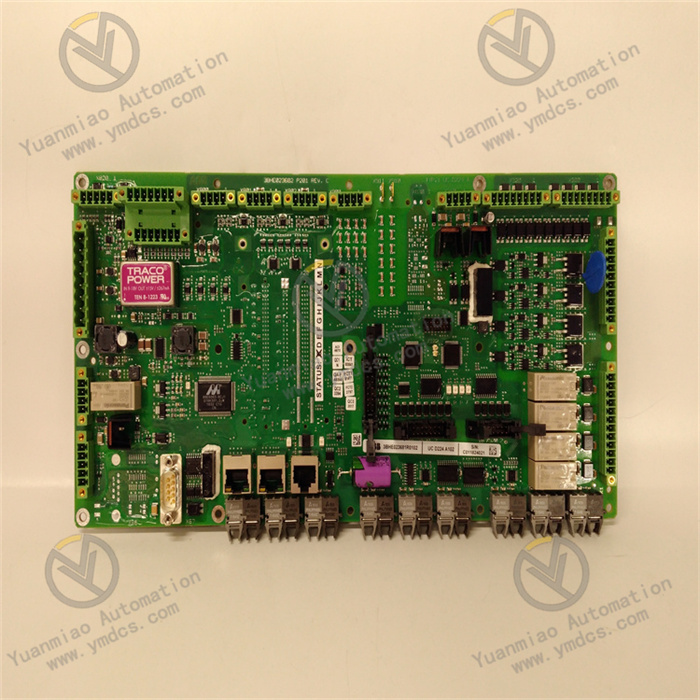

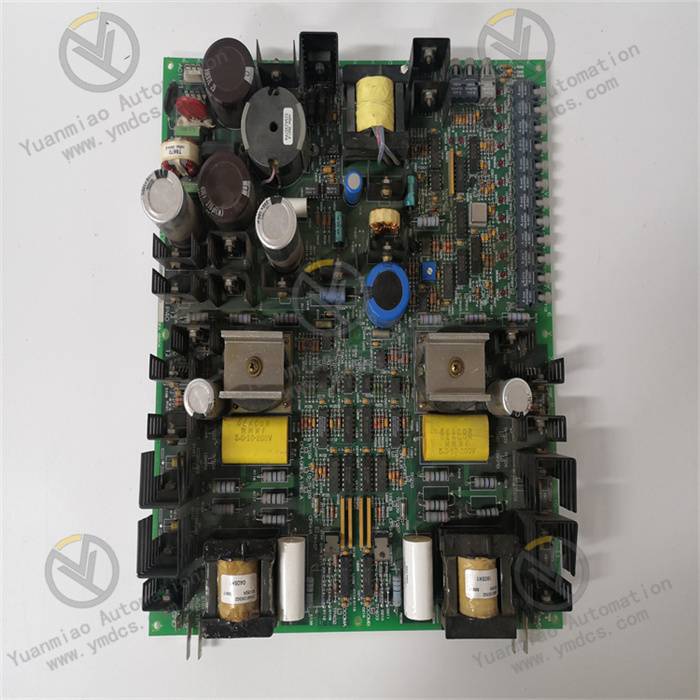

The mainstream servo drivers all use digital signal processor (DSP) as the control core, which can realize more complex control algorithms and realize digitalization, networking and intelligence. Power devices generally use intelligent power module (IPM) as the core design of the drive circuit,IPM internal integrated drive circuit, and has overvoltage, overcurrent, overheating, undervoltage and other fault detection protection circuit, in the main circuit also add a soft start circuit to reduce the impact of the start process on the driver. The power drive unit first rectifies the input three-phase or mains through the three-phase full-bridge rectifier circuit to obtain the corresponding direct current. The three-phase permanent magnet synchronous AC servo motor is driven by the three-phase sinusoidal PWM voltage inverter after the rectified three-phase power or mains. The whole process of the power drive unit can be simply said to be the AC-DC-AC process. The main topological circuit of the rectifier unit (AC-DC) is the three-phase full-bridge uncontrolled rectifier circuit.

With the large-scale application of servo system, the use of servo drive, servo drive debugging, servo drive maintenance are more important technical issues in today's servo drive, more and more industrial control technology service providers have conducted in-depth research on servo drive technology. Servo drive is an important part of modern motion control, which is widely used in industrial robots and CNC machining centers and other automation equipment. In particular, the servo drive used to control AC permanent magnet synchronous motor has become a research hotspot at home and abroad. The current, speed and position-3 closed-loop control algorithm based on vector control is widely used in the design of AC servo drivers. Whether the speed closed-loop design in this algorithm is reasonable or not plays a key role in the whole servo control system, especially in the performance of speed control.

Basic requirement

Requirements for servo feed systems

1, wide speed range

2, high positioning accuracy

3, has sufficient transmission rigidity and high speed stability

4, fast response, no overshoot

In order to ensure productivity and processing quality, in addition to requiring a high positioning accuracy, it also requires a good fast response characteristics, that is, the response of the tracking command signal is required to be fast, because the numerical control system in the start and brake, the acceleration and deceleration are required to be large enough to shorten the transition process time of the feed system and reduce the contour transition error.

5, low speed large torque, strong overload capacity

In general, the servo drive has more than 1.5 times the overload capacity in a few minutes or even half an hour, and can be overloaded 4 to 6 times in a short period of time without damage.

6, high reliability

The feed drive system of CNC machine tool is required to have high reliability, good working stability, strong adaptability to the environment such as temperature, humidity, vibration and strong anti-interference ability.

Requirements for motors

1, from the lowest speed to the highest speed motor can run smoothly, torque fluctuation is small, especially at low speed such as 0.1r/min or lower speed, there is still a stable speed without crawling phenomenon.

2, the motor should have a large overload capacity for a long time to meet the requirements of low speed and high torque. General DC servo motors require 4 to 6 times overload in a few minutes without damage.

3, in order to meet the requirements of fast response, the motor should have a small moment of inertia and a large locked-rotor moment, and have as small a time constant and starting voltage as possible.

4, the motor should be able to withstand frequent starting, braking and reversal.

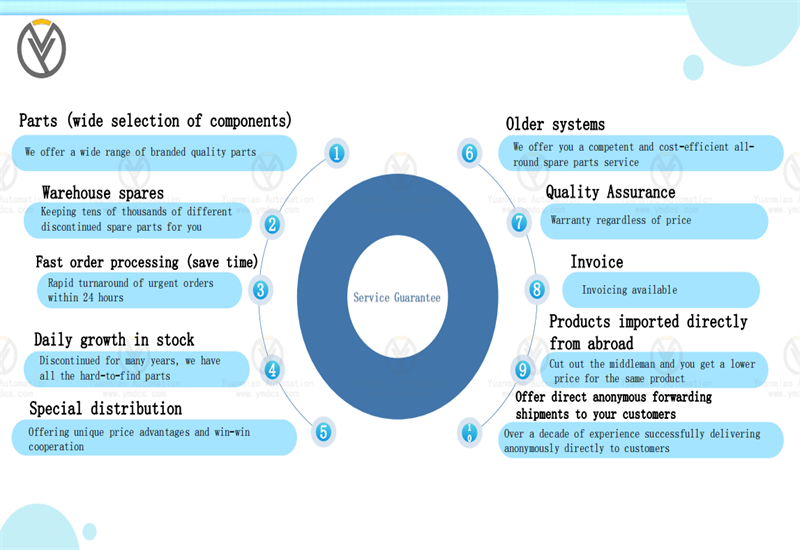

The company focuses on DCS, PLC, robot, large servo four systems

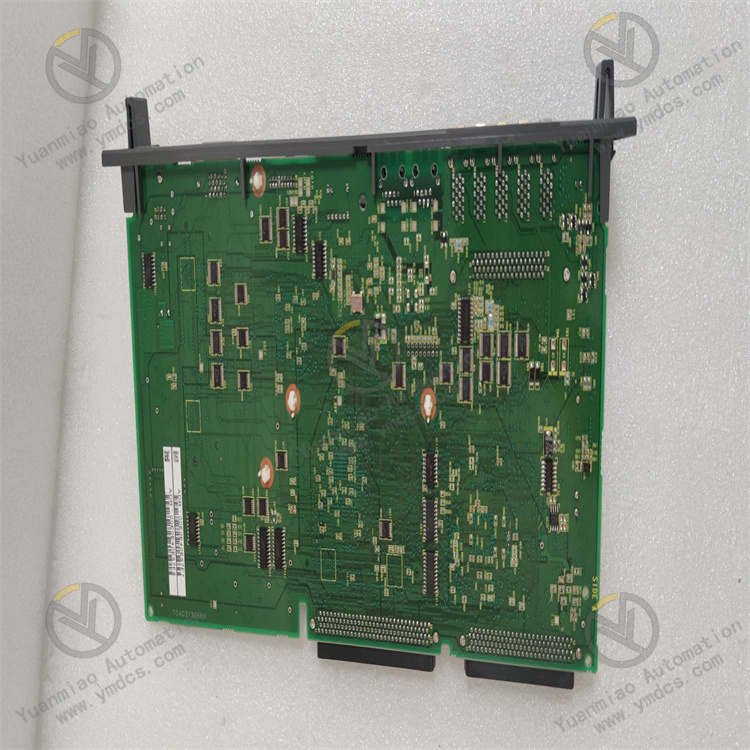

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:https://www.ymdcs.com/Fanuc/