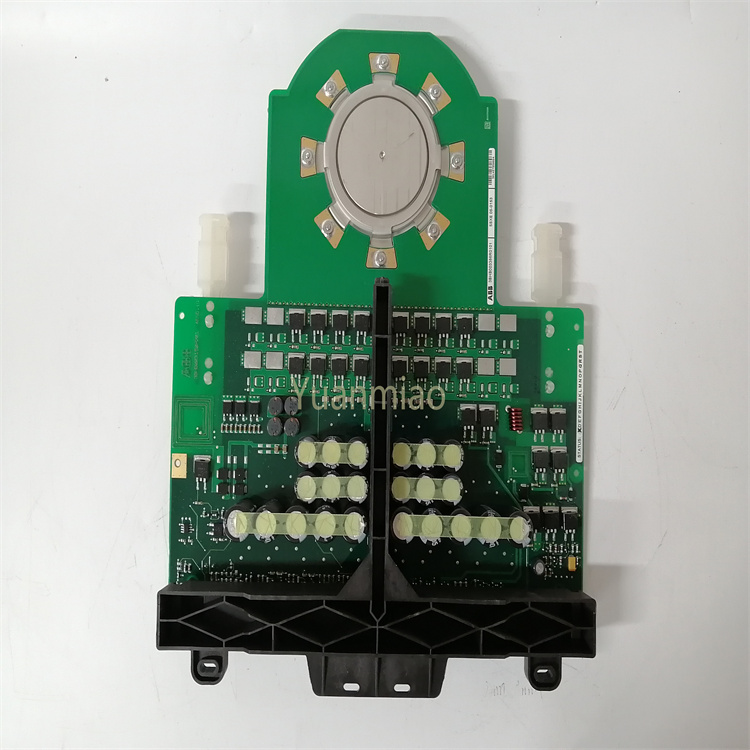

Description

Bently Nevada (Bentley Nevada) is a leading supplier and service provider of mechanical protection and continuous operation condition monitoring systems for equipment. The company's products are widely used in oil and gas, oil and gas transmission pipelines, pulp and paper, metallurgy, mining, food and pharmaceutical Marine engines and many other fields. Its on-line mechanical condition monitoring technology is a world leader. The main series products are: 1, mechanical equipment continuous operation status monitoring system 2, wireless and distributed monitoring system 3, portable vibration analyzer and data acquisition instrument 4, detection sensor: including vibration, displacement, speed, pressure, energy, temperature sensor The 3500 system is a world leader in detecting and preventing false trips and false trips of rotating machinery. With more than 85,000 units installed worldwide, it provides automatic protection value by tripping monitored machines to prevent costly damage if needed. The 3500 system also protects your machines and processes from false trips that can cause your operations to be disrupted for no reason, resulting in costly downtime or lost production. When connected to our System 1 † software, it also provides continuous condition monitoring information for use in proactive maintenance programs. The 3500 system combines the industry's broadest selection of mechanical measurement parameters with a software configuration for almost all mechanical monitoring scenarios.

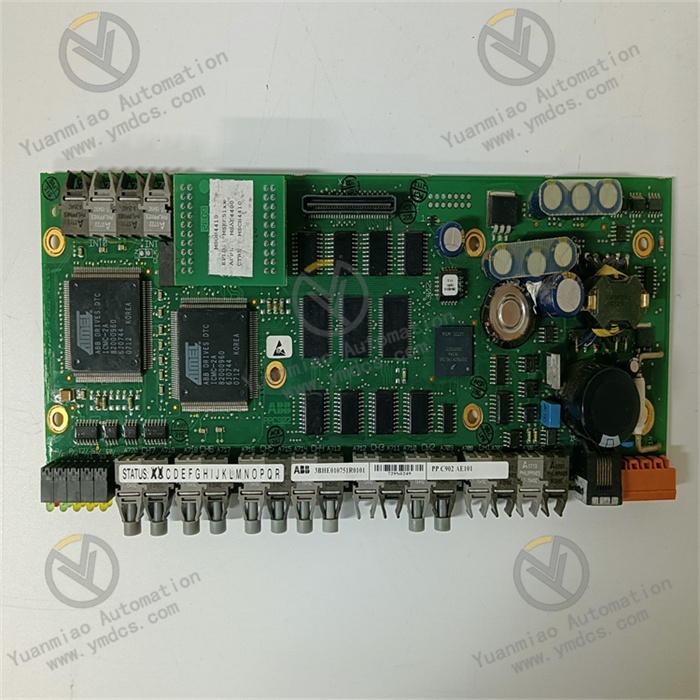

The 3500 Transient Data Interface (TDI) is the interface between the 3500 monitoring System and the Bentley System 1TM machine management software. TDI combines the capabilities of 3500/20 Framework Interface Modules (RIM) and communication processors such as TDXnet. The TDI runs in the RIM slot of the 3500 frame and is used in conjunction with the M Series monitor (3500/40M, 3500/42M, etc.) to continuously collect steady-state and transient waveform data and transmit the data to the main computer software via Ethernet. TDI has standard static data acquisition, but enables the disk with an optional channel to also capture transient or dynamic data. In addition to integrating the capabilities of the communication processor into the 3500 framework, TDI has several other improvements over previous communication processors. TDI provides common functionality to the entire framework, but is not part of the critical monitoring channel and does not affect the correct and regular operation of the overall monitoring system. Each framework requires one TDI or RIM. The TDI occupies only one slot in the frame and must be located in the first slot (next to the power module). For triple module redundancy (TMR) applications, the 3500 system requires TDI in the form of TMR. In addition to all the features of the standard TDI, the TMR TDI also has a "Monitor channel comparison function". The 3500TMR configuration performs the monitoring voting function by selecting the installation function of the monitor option. In this way, TMR TDI continuously compares the outputs of three redundant monitors. If TMR TDI detects that the output of one monitor is not equal to that of the other two monitors (within a percentage of the configuration), it issues an error indication to the monitor and adds an event to the system event list. The 3500 system is used to continuously monitor rotating and reciprocating machinery used in a variety of industries, especially in automatic shutdown machine protection applications that require extremely high reliability and availability. The types of machines that can use the Bentley 3500 system include, but are not limited to: Gas turbines, steam turbines, compressors, turbo expanders, electric motors and generators, exciters, gearboxes, pumps, fans, fans, reciprocating compressors, extruders and ball making machines. The available Bentley (bently3500 Series) monitor module channel types are as follows: Radial vibration, axial (lateral) displacement, differential expansion, speed, acceleration, shell expansion, valve position, standard tachometer, overspeed tachometer, shaft vibration, standard single slope differential expansion, double slope differential expansion, zero speed tachometer, etc.

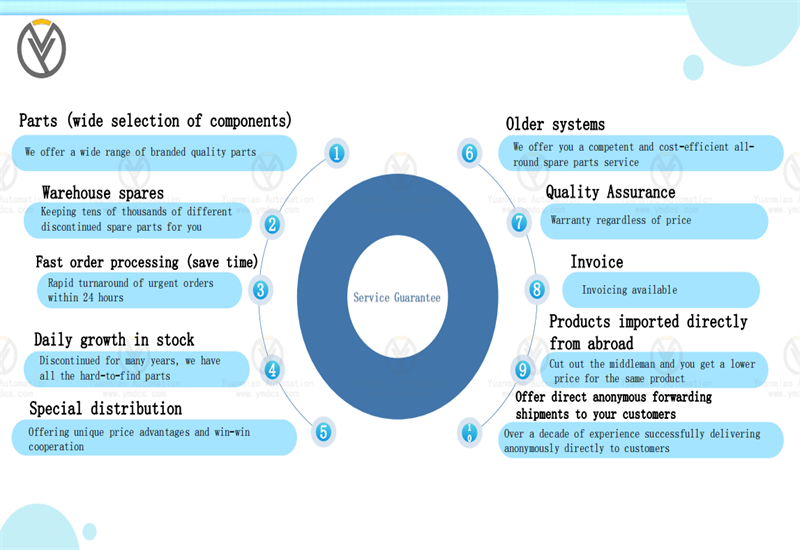

The company focuses on DCS, PLC, robot, large servo four systems

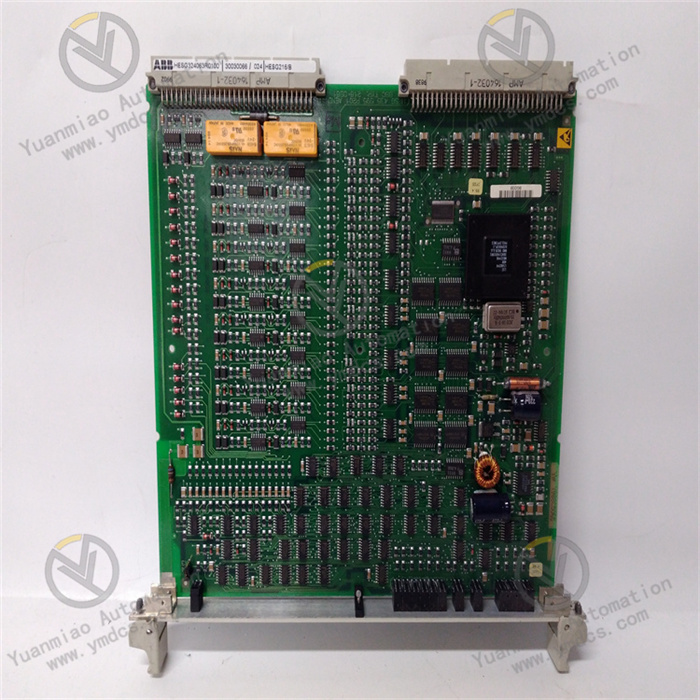

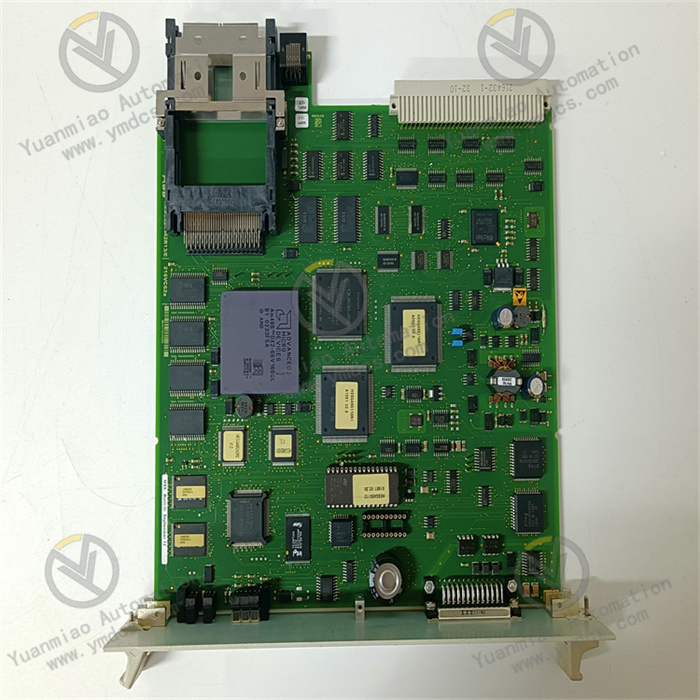

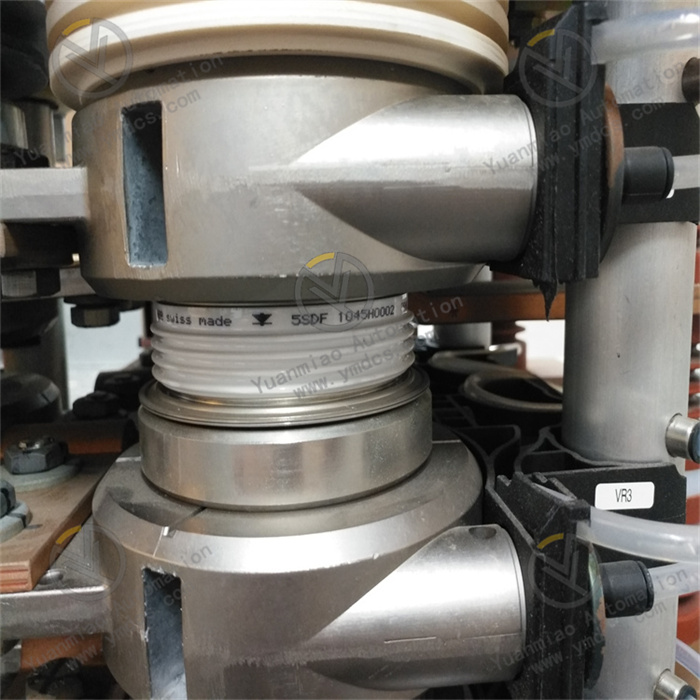

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/BentlyNevada/