Description

The Bently Nevada 330500 - 02 - CN is a piezoelectric vibration velocity sensor, which is commonly used for monitoring the vibration of machinery and equipment in the industrial field. Product Features High-precision Measurement: It can accurately measure the absolute vibration of the machine's bearing housing, casing or structure. The measurement range is from 0 to 2500 rpm, and the accuracy can reach ±1% of the reading or ±1 rpm. Wide Frequency Response: The frequency response is from 4.5 Hz to 5 kHz (270 cpm to 300 kcpm) ±3.0 dB. In the range of 6.0 Hz to 2.5 kHz (360 cpm to 150 kcpm), the accuracy is higher, up to ±0.9 dB. It can effectively capture vibration signals of different frequencies. Multiple Installation Methods: Using solid-state electronic components, it can be installed vertically, horizontally or at any angular direction, which is convenient for installation and monitoring on different devices and in different positions. Long Cable Support: The maximum cable length can reach 305 meters (1000 feet), facilitating signal transmission in large industrial equipment or complex production environments. Good Environmental Adaptability: The operating temperature range is from -55°C to 121°C. The housing material is 316L stainless steel, and the protection level is IP65. It can adapt to harsh industrial environments and ensure stable operation under different temperature, humidity and corrosive environments.

Technical Parameters Sensitivity: 3.94 mV/mm/s (100 mV/in/s) ±5%. Power Supply: 9 to 32 V DC. Weight: 142 g. Diameter: 25.3 mm. Height: 63.2 mm. Output Type: Analog signal. Connection Method: M8x0.75 screw terminal.

Application Areas: It is widely applied in enterprises such as power plants, refineries, chemical plants, steel plants, water pump factories, and fan factories. It is used for online measurement and protection of the casings of large rotating machinery shafts such as steam turbines, water turbines, blowers, compressors, air separation units, gearboxes, and water pumps. By monitoring the vibration velocity, it can evaluate the operating status of the equipment, detect potential fault hazards in a timely manner, and provide a basis for the preventive maintenance of the equipment.

Installation and Connection: It is usually installed on the bearing housing, casing or structure of the machinery and equipment, and fixed with the M8x1 installation thread. When connecting, the sensor is connected to the monitoring system (such as Bently Nevada's 3500/42M vibration module, 1900/65A or 2300/20 vibration monitor, etc.) through a double-core shielded cable to achieve the transmission and processing of vibration signals. Signal Processing Method:

Signal Generation: This sensor works based on the piezoelectric effect. When the machinery and equipment vibrate, the piezoelectric elements inside the sensor will be affected by mechanical stress, thus generating a charge signal proportional to the vibration velocity. Since the charge signal generated by the piezoelectric elements is very weak, it needs to be converted into a voltage signal first for subsequent processing.

Amplification: The built-in electronic circuit of the sensor will amplify the converted weak voltage signal. Through the amplifier circuit, the weak signal is amplified to an appropriate amplitude, generally making it within the range that can be processed by subsequent monitoring equipment. The sensitivity of this sensor is 3.94 mV/mm/s (100 mV/in/s) ±5%, and the amplified signal can more clearly reflect the vibration situation of the equipment.

Filtering: The amplified signal may contain noise and interference signals of various frequency components. In order to extract the useful signal that truly reflects the vibration characteristics of the equipment, a filter circuit is used to filter the signal. According to the frequency response range of this sensor from 4.5 Hz to 5 kHz (270 cpm to 300 kcpm) ±3.0 dB, by setting an appropriate filter, the vibration signals within a specific frequency range are allowed to pass through, while suppressing the noise and interference of other frequencies, improving the quality and accuracy of the signal.

Signal Transmission: The signal processed by amplification and filtering is transmitted through a double-core shielded cable. The shielded cable can effectively reduce the impact of external electromagnetic interference on the signal and ensure the integrity of the signal during the transmission process. The maximum cable length of this sensor can reach 305 meters (1000 feet), which can meet the signal transmission requirements in large industrial equipment or complex production environments.

Signal Reception and Analysis: The signal transmitted to the monitoring system (such as Bently Nevada's 3500/42M vibration module, 1900/65A or 2300/20 vibration monitor, etc.) will be further processed and analyzed. The monitoring system will sample and digitize the signal, and calculate various parameters of the equipment vibration, such as vibration velocity, acceleration, displacement, etc. according to the preset algorithms and thresholds. At the same time, the monitoring system will also conduct real-time monitoring and trend analysis of these parameters to detect the abnormal vibration of the equipment in a timely manner and provide a basis for the operation and maintenance of the equipment.

Signal Processing Method:

Signal Generation: This sensor works based on the piezoelectric effect. When the machinery and equipment vibrate, the piezoelectric elements inside the sensor will be affected by mechanical stress, thus generating a charge signal proportional to the vibration velocity. Since the charge signal generated by the piezoelectric elements is very weak, it needs to be converted into a voltage signal first for subsequent processing.

Amplification: The built-in electronic circuit of the sensor will amplify the converted weak voltage signal. Through the amplifier circuit, the weak signal is amplified to an appropriate amplitude, generally making it within the range that can be processed by subsequent monitoring equipment. The sensitivity of this sensor is 3.94 mV/mm/s (100 mV/in/s) ±5%, and the amplified signal can more clearly reflect the vibration situation of the equipment.

Filtering: The amplified signal may contain noise and interference signals of various frequency components. In order to extract the useful signal that truly reflects the vibration characteristics of the equipment, a filter circuit is used to filter the signal. According to the frequency response range of this sensor from 4.5 Hz to 5 kHz (270 cpm to 300 kcpm) ±3.0 dB, by setting an appropriate filter, the vibration signals within a specific frequency range are allowed to pass through, while suppressing the noise and interference of other frequencies, improving the quality and accuracy of the signal.

Signal Transmission: The signal processed by amplification and filtering is transmitted through a double-core shielded cable. The shielded cable can effectively reduce the impact of external electromagnetic interference on the signal and ensure the integrity of the signal during the transmission process. The maximum cable length of this sensor can reach 305 meters (1000 feet), which can meet the signal transmission requirements in large industrial equipment or complex production environments.

Signal Reception and Analysis: The signal transmitted to the monitoring system (such as Bently Nevada's 3500/42M vibration module, 1900/65A or 2300/20 vibration monitor, etc.) will be further processed and analyzed. The monitoring system will sample and digitize the signal, and calculate various parameters of the equipment vibration, such as vibration velocity, acceleration, displacement, etc. according to the preset algorithms and thresholds. At the same time, the monitoring system will also conduct real-time monitoring and trend analysis of these parameters to detect the abnormal vibration of the equipment in a timely manner and provide a basis for the operation and maintenance of the equipment.

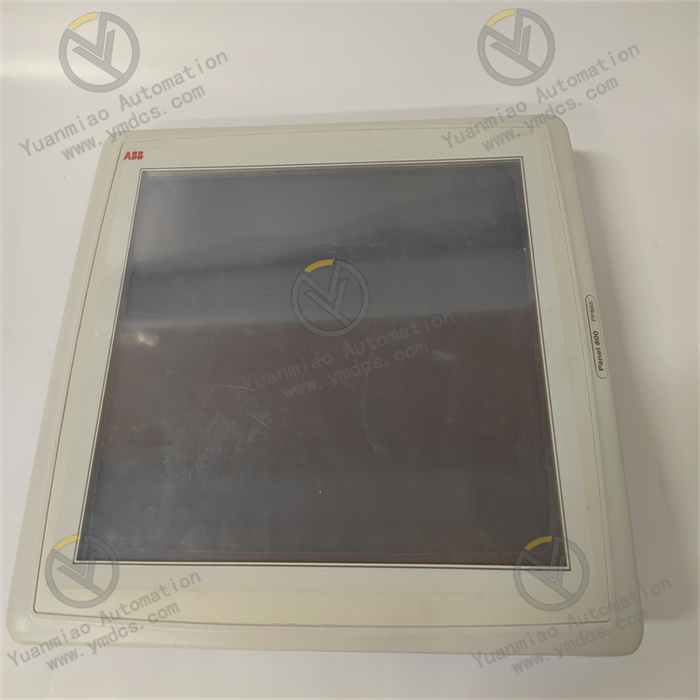

Main Products:

Covering world-renowned brands:

Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM

Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries.

Service Advantages:

✅ Original imports with quality assurance

✅ Ample stock for rapid delivery

✅ Professional team for technical support

✅ Global logistics for worry-free coverage