Description

General Information

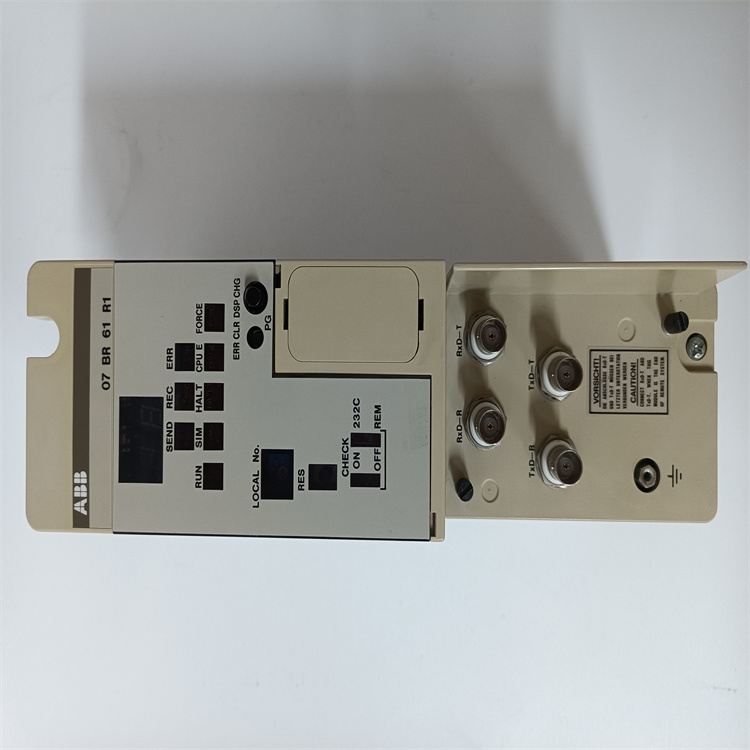

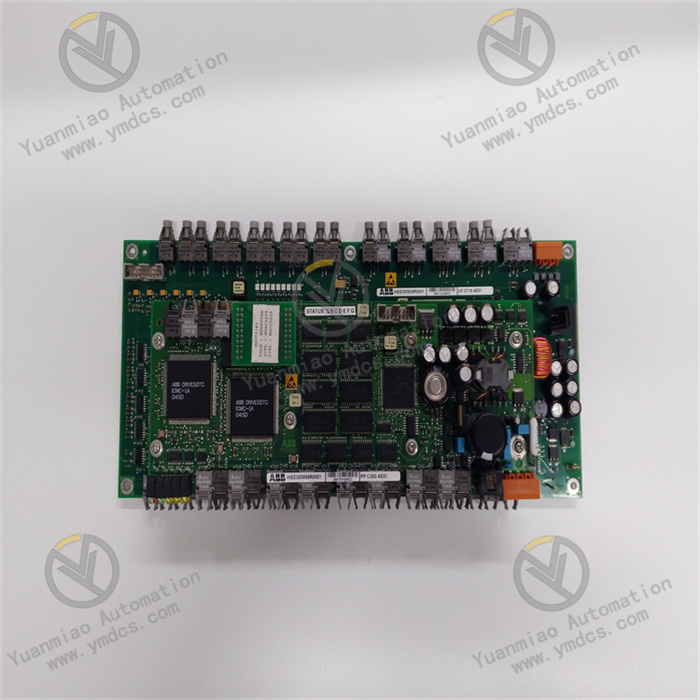

- Product ID:SPBRC400

- Catalog Description:Controller with Expanded Memory

Dimensions

- Product Net Depth / Length:71.12 mm

- Product Net Height:358.14 mm

- Product Net Width:271.78 mm

- Product Net Weight:0.499 kg

Environmental

- WEEE Category:5. Small Equipment (No External Dimension More Than 50 cm)

- Number of Batteries:1

- Battery Chemical Composition:Lithium

- Battery Type:Button Cell

- Battery Weight:5 g

The SPBRC400 Extended Memory controller is a controller with extended memory capability that is commonly used in industrial automation environments. It has a high degree of flexibility and scalability, and can meet the needs of large-scale data storage and processing in industrial automation systems. Here are some of the key features of the SPBRC400 extended memory controller: Extended Memory capabilities: The controller provides additional storage space, allowing users to store more data and information in industrial automation systems. This is very useful for application scenarios where large amounts of data need to be processed, such as production process monitoring, quality control, etc. Suitable for industrial environments: The SPBRC400 controller is designed for stable operation in harsh industrial environments. It may have high temperature resistance, dust resistance, shock resistance and other characteristics to ensure reliable operation in complex industrial sites. Scalability: The controller supports the connection and integration with other devices and systems, and has good scalability. Users can add additional functional modules or interfaces as needed to meet specific application requirements. High performance: The SPBRC400 controller may use a high-performance processor and optimized algorithms to provide fast data processing capabilities and response speed. This helps ensure the real-time and accuracy of industrial automation systems. Easy to program and configure: The controller may support multiple programming languages and development environments, making it easy for users to program and configure. Users can flexibly customize the functions and behaviors of the controller according to the specific application requirements.

Programmable controller (hereinafter referred to as PLC) from its generation to the present, the realization of wiring logic to storage logic leap; Its function from weak to strong, to achieve the progress of logic control to digital control; Its application field has grown from small to large, realizing simple control of single equipment to competent motion control, process control and distributed control and other tasks. Today's PLC in the processing of analog, digital computing, man-machine interface and network capabilities have been greatly improved, become the mainstream control equipment in the field of industrial control, in all walks of life is playing an increasing role.

Application field of PLC

At present, PLC has been widely used in steel, petroleum, chemical, electric power, building materials, machinery manufacturing, automobile, textile, transportation, environmental protection and cultural entertainment and other industries at home and abroad, the use is mainly divided into the following categories:

1. Switch quantity logic control

Instead of the traditional relay circuit, it can realize logic control and sequence control, which can be used for the control of a single device, and can also be used for multi-machine group control and automatic pipeline. Such as injection molding machines, printing presses, stapler machines, combined machine tools, grinding machines, packaging production lines, electroplating lines, etc.

2. Industrial process control

In the industrial production process, there are some continuous changes such as temperature, pressure, flow, liquid level and speed (that is, the analog amount), PLC uses the corresponding A/D and D/A conversion modules and a variety of control algorithms to deal with the analog amount, complete closed-loop control. PID regulation is a kind of regulation method used in general closed-loop control system. Process control is widely used in metallurgy, chemical industry, heat treatment, boiler control and so on.

3. Motion control

PLC can be used to control circular or linear motion. Generally use special motion control modules, such as single-axis or multi-axis position control modules that can drive stepper motors or servo motors, widely used in various machinery, machine tools, robots, elevators and other occasions.

4. Data processing

PLC has mathematical operations (including matrix operations, function operations, logical operations), data transmission, data conversion, sorting, table lookup, bit operation and other functions, can complete the data collection, analysis and processing. Data processing is generally used in some large control systems in the paper, metallurgy, and food industries.

5. Communication and networking

PLC communication includes communication between PLC and communication between PLC and other intelligent devices. With the development of factory automation network, PLC now has a communication interface, communication is very convenient.

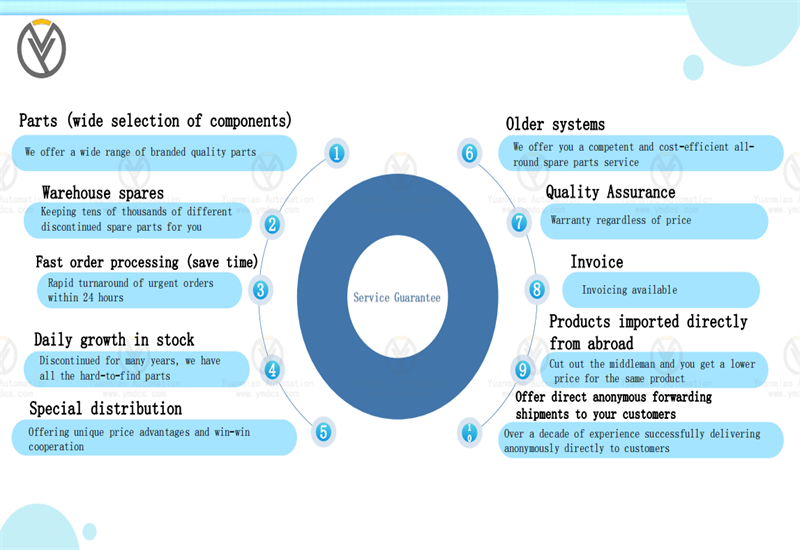

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers Company advantage: Supply imported original products, professional production of spare parts One year warranty, fast delivery time, complete supply !!! ① 24 hours email response (12 hours); ② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/ABB/