Description

Power unit board 1. Unit power supply board Board function: Take power from the DC bus of the power unit and output 24V DC power for the unit control board. Board interface: Input interface: power unit positive and negative DC bus Output interface: 24VDC output, connected to the unit control board 2. Unit control panel Plate function: 1) Receive the signal of the main control system and provide the control signal to the drive board; 2) Perform real-time fault monitoring and report fault information to the main control system; 3)3) Supply power to the unit drive board. Board interface: 1) Optical fiber interface for communication with the main control system; 2)24V power input interface: connected with the power board; 3) Driver signal (Top1, Top2, Lock interface: connected with the driver board; 4)15V power output interface: connected with the driver board to supply power to the driver board; 5) Overvoltage, undervoltage detection interface: connected with the positive and negative bus of the unit; 6) Lack of phase detection interface: fuse auxiliary switch; 7) overheating detection interface: connected to the temperature detection switch; 8) Power on thyristor drive signal interface: Connect the thyristor gate; 9) By-pass thyristor driver signal interface: connected to the by-pass thyristor gate; 10) Bypass OK signal detection interface: connected to bypass OK board. 3. Unit drive board Function of the board: receive the control signal of the unit control board, provide driving signal for the four-way IGBT on the unit, and monitor the drive fault and report it to the unit control board. Board interface: 1)15V power input interface: connected to the unit control board; 2) Input signal (Top1, Top2, /Lock) : connected to the unit control board; 3) Output signal (ERRout) : connected to the unit control board; 4) Output signal (TOP1, BOT1, TOP2, BOT2 IGBT driver signal) : connected to the C, G, E pole of TOP1, BOT1, TOP2, BOT2 IGBT respectively. 4. Bypass OK board Board function: After the unit control board sends out the side communication number, the by-pass loop is detected to detect the signal input to the unit control board. Board interface: Input interface: bypass thyristor A, K pole; Output interface: connected to the unit control board

The Programmable Logic Controller was first introduced in the United States in the late 1960s, when it was called the Programmable Logic Controller (PLC), which was used to replace relays. To perform logical judgment, timing, counting and other sequential control functions. The concept of PLC was proposed by General Motors. The basic design idea of PLC is to combine the advantages of computer function perfect, flexible, universal and relay control system simple and easy to understand, easy to operate, cheap and so on, the controller hardware is standard and universal. According to the actual application object, the control content is compiled into software and written into the user program memory of the controller, so that the connection between the controller and the controlled object is convenient.

PLC features and functions

(1) The main characteristics of plc. The characteristics of plc are: reliable work, fast running speed, building block structure, flexible combination, good compatibility, simple programming and generation, rich, strong network function.

(2) The main functions of plc. plc system can well complete the industrial real-time sequence control, condition control, counting control, step control and other functions; It can complete analog/digital (a/d), digital/analog (d/a) conversion, data processing, communication networking, real-time monitoring and other functions. Years of practice shows that plc, reliable, is designed for the factory, with reinforced components according to the requirements of the working environment, real-time scanning practice and fault diagnosis function, easy troubleshooting, won the preference of users. What makes a plc so reliable is a real-time core or operating system of executable relay logic, sequential function diagrams, function blocks, structured text, command catalogs, or a combination thereof. In case of failure, the built-in device can maintain mechanical damage and maintain an orderly and predictable sequence.

2.4 The development trend of plc: there are extremely fast logical operations and logic control, sequence control capabilities, reliability in discrete control, convenient and easy to learn programming methods, so that it has an undisputed position in the field of industrial automation based on discrete.

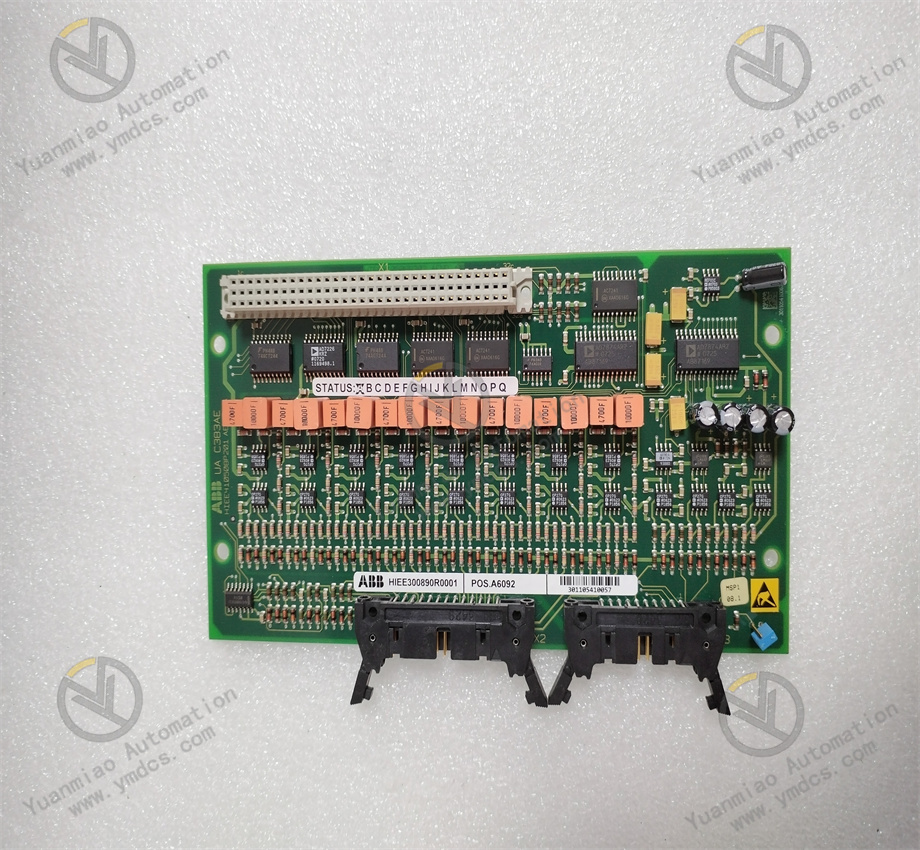

ABB power module features and applications

ABB power module uses advanced integrated circuit technology to integrate power devices and logic control circuits in a highly integrated, fully sealed integrated block with power function. The power module has the advantages of convenient use and reliable performance, which represents the development direction of power supply technology. Because the switching power supply has the advantages of high efficiency and small size, it is suitable for integration. Because of its low efficiency, generally about 50%, it is difficult to achieve high-power (more than 100W) integration. The power module introduced by Jimi technology refers to the switching power module, focusing on the DC/DC converter. Today's switching power modules can reach hundreds of watts or even kilowatts.

Power module products mainly include DC/DC converter module, power factor correction module, AC input module, etc. Their main characteristics are:

◆ ABB power module working frequency is high, generally 300KHz~1MHz.

◆ ABB power module size is small, ultra-thin, thickness is generally less than 20mm, light weight, generally less than 200g.

◆ ABB power module power density is large, generally 5~10W/ cubic centimeter.

◆ ABB power module is easy to use, less external components, can be expanded in parallel, and can also realize logic control and remote control.

◆ ABB power module is suitable for a wide range of power grid voltage changes. When the general AC voltage fluctuates between 150V and 280V, the output has a voltage regulator function.

◆ ABB power module temperature adaptation range is wide, can be from -55 degrees Celsius ~+100 degrees Celsius, the general high temperature substrate temperature is +85 degrees Celsius, low temperature 0 degrees, -20 degrees, -40 degrees, -55 degrees and other levels.

◆ ABB power module fully sealed package, with three anti-function, waterproof, dustproof, anti-impact.

◆ ABB power modules generally use zero voltage switch or zero current switch technology, good electromagnetic compatibility.

◆ ABB power module structure is highly standardized and easy to install.

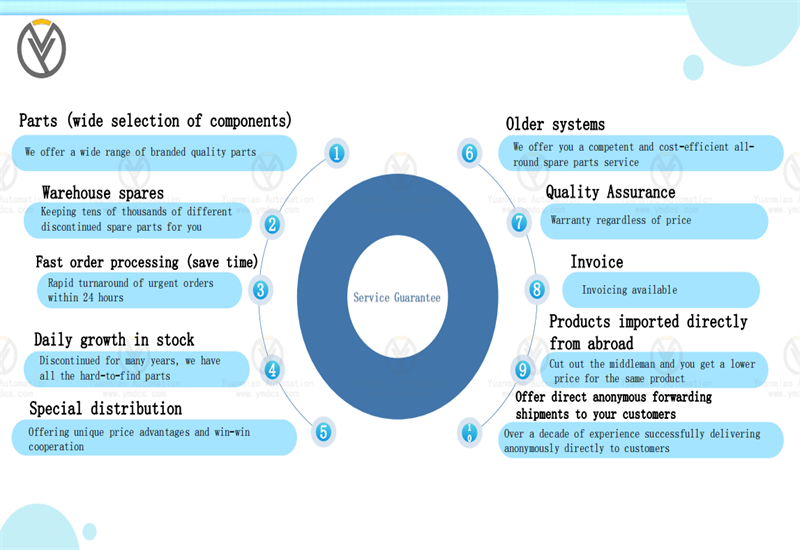

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers Company advantage: Supply imported original products, professional production of spare parts One year warranty, fast delivery time, complete supply !!! ① 24 hours email response (12 hours); ② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/ABB/