Description

ABB power module features and applications ABB power module uses advanced integrated circuit technology to integrate power devices and logic control circuits in a highly integrated, fully sealed integrated block with power function. The power module has the advantages of convenient use and reliable performance, which represents the development direction of power supply technology. Because the switching power supply has the advantages of high efficiency and small size, it is suitable for integration. Because of its low efficiency, generally about 50%, it is difficult to achieve high-power (more than 100W) integration. The power module introduced by Jimi technology refers to the switching power module, focusing on the DC/DC converter. Today's switching power modules can reach hundreds of watts or even kilowatts. Power module products mainly include DC/DC converter module, power factor correction module, AC input module, etc. Their main characteristics are: ◆ ABB power module working frequency is high, generally 300KHz~1MHz. ◆ ABB power module size is small, ultra-thin, thickness is generally less than 20mm, light weight, generally less than 200g. ◆ ABB power module power density is large, generally 5~10W/ cubic centimeter. ◆ ABB power module is easy to use, less external components, can be expanded in parallel, and can also realize logic control and remote control. ◆ ABB power module is suitable for a wide range of power grid voltage changes. When the general AC voltage fluctuates between 150V and 280V, the output has a voltage regulator function. ◆ ABB power module temperature adaptation range is wide, can be from -55 degrees Celsius ~+100 degrees Celsius, the general high temperature substrate temperature is +85 degrees Celsius, low temperature 0 degrees, -20 degrees, -40 degrees, -55 degrees and other levels. ◆ ABB power module fully sealed package, with three anti-function, waterproof, dustproof, anti-impact. ◆ ABB power modules generally use zero voltage switch or zero current switch technology, good electromagnetic compatibility. ◆ ABB power module structure is highly standardized and easy to install.

IGCT integrated Gate Commutated Thyristors (IGCT integrated gate commutated thyristors = gate commutated thyristors + gate units) is a new type of power semiconductor switching device developed by medium voltage inverter for use in large power electronics packages. It was proposed by ABB in 1997. IGCT has made great progress in power, reliability, switching speed, efficiency, cost, weight and volume, and has brought a new leap to power electronic complete sets. IGCT integrates the GTO chip with the anti-parallel diode and gate drive circuit, and then connects it with the gate driver in a low inductance mode at the periphery, combining the stable turn-off ability of the transistor and the advantages of the low on-state loss of the thyristor, and gives play to the performance of the thyristor in the on-stage, and presents the characteristics of the transistor in the off-stage. IGCT has the characteristics of large current, high blocking voltage, high switching frequency, high reliability, compact structure, low on-off loss and so on, and has a good application prospect. IGCT has been used in power system grid devices (100MVA) and medium power industrial drive devices (5MW) IGCT has been successfully applied in the field of medium voltage inverter for 11 years (until 2009), because the high-speed switching capability of IGCT does not need buffer circuits, so the number of power components required is less, and the reliability of operation is greatly increased.

Insulated Gate Bipolar Transistor (IGBT), It is a composite voltage-driven power electronic device composed of BJT(bipolar triode) and MOS(insulated gate type field effect tube), which has the advantages of high input impedance of MOSFET and low on-voltage drop of GTR. The driving power is small and the saturation pressure is reduced. The diode is added between the collector and the emitter, mainly for continuous flow, and due to the inductive load, the IGBT turn-off moment will produce a very high self-inductive reverse voltage at both ends of the IGBT, which may breakdown the IGBT. The parallel diode shorted out this "self-inducted inverting voltage", protecting the IGBT.

Servo motor, according to the requirements of the control command, the power is amplified, transformed and regulated, so that the torque, speed and position control of the output of the drive device is very flexible and convenient.

Because of its "servo" performance, it is named as a servo motor. Its function is to convert the input voltage control signal into the angular displacement and angular velocity output on the axis drive control object.

Servo motors are generally divided into two categories: DC servo motors and AC servo motors.

Ac servo motor

The rotor inside the AC servo motor is a permanent magnet, and the U/V/W three-phase electricity controlled by the driver forms an electromagnetic field, and the rotor rotates under the action of this magnetic field, while the encoder of the motor comes with a feedback signal to the driver, and the driver adjusts the rotor rotation Angle according to the feedback value and the target value.

When the AC servo motor has no control voltage, only the pulsating magnetic field generated by the excitation winding is in the stator, and the rotor is stationary. When there is a control voltage, a rotating magnetic field is generated in the stator, the rotor rotates in the direction of the rotating magnetic field, in the case of constant load, the speed of the motor changes with the size of the control voltage, when the phase of the control voltage is opposite, the servo motor will reverse.

Dc servo motor

The working principle of DC servo motor is basically the same as that of ordinary DC motor. Electromagnetic torque is generated by the action of armature air flow and air gap flux to make the servo motor rotate. The armature control method is usually used to change the speed by changing the voltage while keeping the excitation voltage unchanged. The smaller the voltage, the lower the speed. When the voltage is zero, stop rotating. Because when the voltage is zero, the current is also zero, so the motor will not produce electromagnetic torque, neither will there be rotation phenomenon.

Dc servo motor is widely used in numerical control system, but DC servo motor also has some disadvantages: its brush and commutator are easy to wear; The maximum speed limit of the motor, the application environment limit; The structure is complicated, the manufacture is difficult and the cost is high.

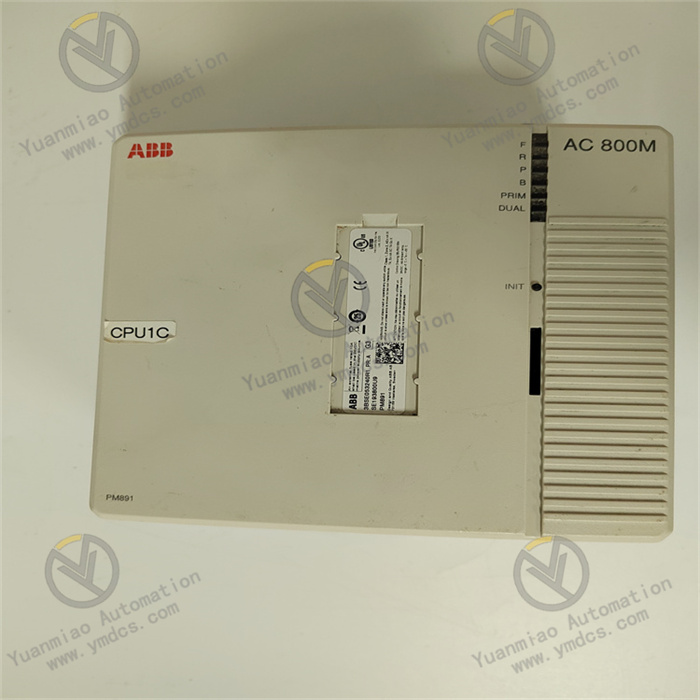

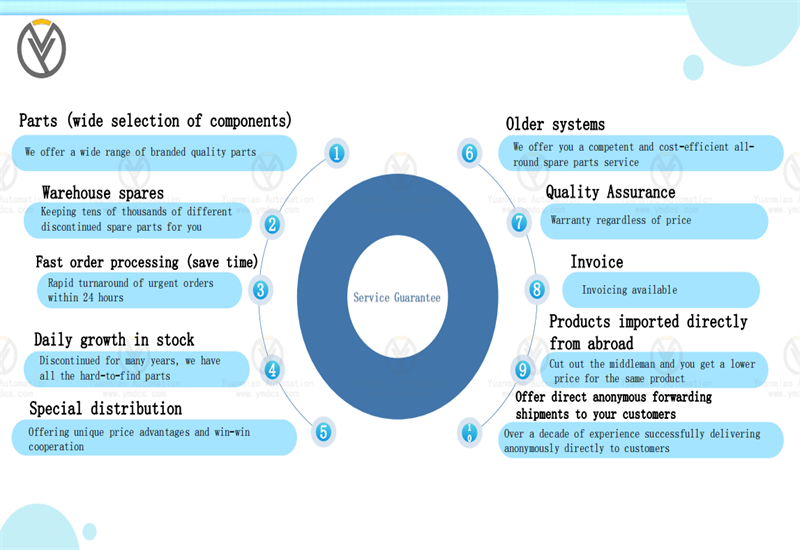

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers Company advantage: Supply imported original products, professional production of spare parts One year warranty, fast delivery time, complete supply !!! ① 24 hours email response (12 hours); ② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/ABB/