Description

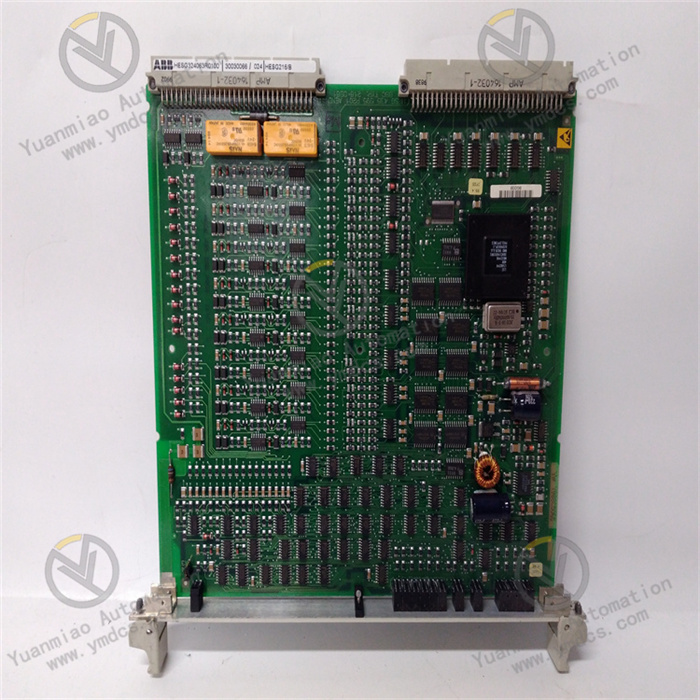

Application characteristics of PLC 1. High reliability, strong anti-interference ability High reliability is the key performance of electrical control equipment. Due to the use of modern large-scale integrated circuit technology, PLC adopts strict production process manufacturing, the internal circuit adopts advanced anti-interference technology, with high reliability. The use of PLC to form a control system, and the relay contactor system of the same size, electrical wiring and switch contacts have been reduced to hundreds or even thousands of one, the fault is greatly reduced. In addition, the PLC has a hardware fault self-detection function, which can issue alarm information in time when there is a failure. In the application software, the user can also program the fault self-diagnosis program of peripheral devices, so that the circuit and equipment other than PLC in the system can also obtain fault self-diagnosis protection. In this way, the whole system will be extremely reliable. 2. Complete set, perfect function, strong applicability PLC development to today, has formed a variety of scale of serialized products, can be used in various scales of industrial control occasions. In addition to logic processing functions, PLC mostly has perfect data computing capabilities and can be used in various digital control fields. A large number of various functional units have emerged, so that PLC has penetrated into various industrial controls such as position control, temperature control, CNC. With the enhancement of PLC communication capability and the development of human-machine interface technology, it is very easy to use PLC to form various control systems. 3. Easy to learn and easy to use, welcomed by engineering and technical personnel PLC is an industrial control equipment for industrial and mining enterprises. Its interface is easy and the programming language is easy to be accepted by engineers and technicians. The graphic symbol of ladder diagram language is quite close to the expression mode and relay circuit diagram, which opens the convenient door for people who are not familiar with electronic circuits, do not understand computer principles and assembly language to engage in industrial control. 4. The design of the system has the advantages of small workload, convenient maintenance and easy transformation

Servo motor, according to the requirements of the control command, the power is amplified, transformed and regulated, so that the torque, speed and position control of the output of the drive device is very flexible and convenient.

Because of its "servo" performance, it is named as a servo motor. Its function is to convert the input voltage control signal into the angular displacement and angular velocity output on the axis drive control object.

Servo motors are generally divided into two categories: DC servo motors and AC servo motors.

Ac servo motor

The rotor inside the AC servo motor is a permanent magnet, and the U/V/W three-phase electricity controlled by the driver forms an electromagnetic field, and the rotor rotates under the action of this magnetic field, while the encoder of the motor comes with a feedback signal to the driver, and the driver adjusts the rotor rotation Angle according to the feedback value and the target value.

When the AC servo motor has no control voltage, only the pulsating magnetic field generated by the excitation winding is in the stator, and the rotor is stationary. When there is a control voltage, a rotating magnetic field is generated in the stator, the rotor rotates in the direction of the rotating magnetic field, in the case of constant load, the speed of the motor changes with the size of the control voltage, when the phase of the control voltage is opposite, the servo motor will reverse.

Dc servo motor

The working principle of DC servo motor is basically the same as that of ordinary DC motor. Electromagnetic torque is generated by the action of armature air flow and air gap flux to make the servo motor rotate. The armature control method is usually used to change the speed by changing the voltage while keeping the excitation voltage unchanged. The smaller the voltage, the lower the speed. When the voltage is zero, stop rotating. Because when the voltage is zero, the current is also zero, so the motor will not produce electromagnetic torque, neither will there be rotation phenomenon.

Dc servo motor is widely used in numerical control system, but DC servo motor also has some disadvantages: its brush and commutator are easy to wear; The maximum speed limit of the motor, the application environment limit; The structure is complicated, the manufacture is difficult and the cost is high.

Cp-s. 1 series single-phase switching power supply

Single-phase 24 V DC switching power supply, from 3 A to 40 A The main advantage

◆ Complete product line of 24 V DC output: from 72 W to 960 W, can be used in various industries, especially OEM field

◆ Wide range AC/DC input, very complete certification, including DNV, and CP-S.1 EMC grade can be installed in the ship's cab, good global versatility The low efficiency is 89%, the high efficiency is 94%, the high efficiency is low power consumption, for customers to save operating costs, and meet the environmental requirements

◆ Provide 150% power margin, duration of 5 s, can start the load with impulse current reliably

◆ Narrow width, can save precious installation space

◆ When the OUTPUT voltage is less than 90% of the set voltage, the relay alarm contact 'OUTPUT OK' will be disconnected, the LED will flash, to provide customers with clear information The main features

◆ Rated output voltage: 24 V DC, range: 24... 28 V DC

◆ Rated output current: 3 A, 5 A, 10 A, 20 A and 40 A Efficiency from 89% to 94%

◆ Output power margin 150%IN, sustainable 5 s

◆ Wide range of AC and DC input, authenticated by a third party The width of the module is very small

Cp-1 series switching power supply

The main advantage Switching of power margin and peak current facilitates system availability Up to 94% high efficiency reduces energy consumption, saves money and space, and reduces heat

◆ Reliable operation in harsh environment under harsh temperature conditions

◆ Coated PCBA version is suitable for dangerous places

◆ Additional redundancy unit CP-C. 1-A-RU achieves true redundancy The main features Rated transmission voltage 24 V DC

◆ Rated output current 5 A, 10 A, 20 A

◆ Rated output power 120 W, 240 W, 480 W

◆ Operation efficiency up to 94%, save the cost during operation

◆ Working environment temperature range -25... + 70

◆ Coated PCBA version can extend the ambient temperature range to -40 during operation... + 70 Natural convection cooling - no forced fan cooling

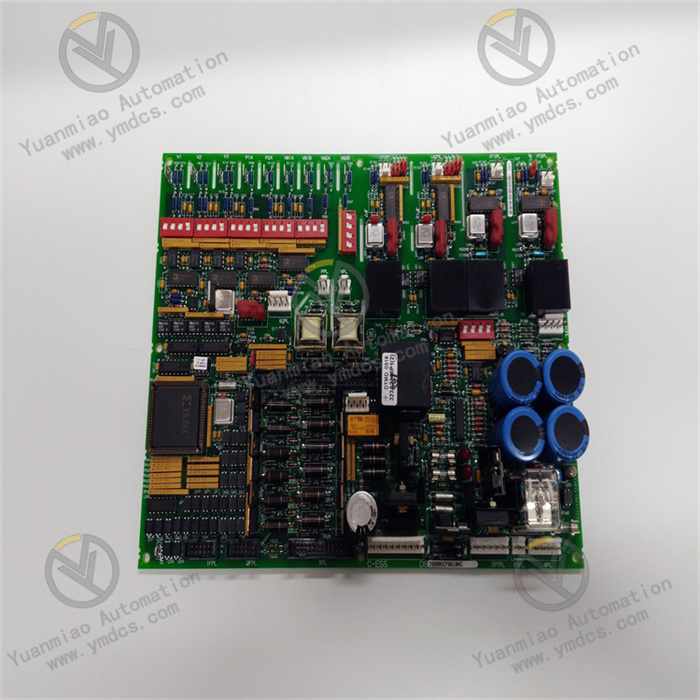

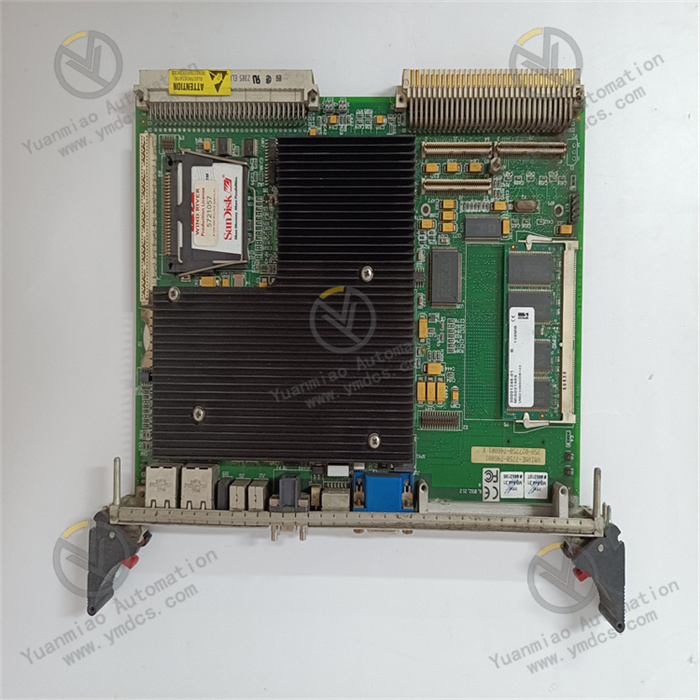

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers Company advantage: Supply imported original products, professional production of spare parts One year warranty, fast delivery time, complete supply !!! ① 24 hours email response (12 hours); ② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/ABB/