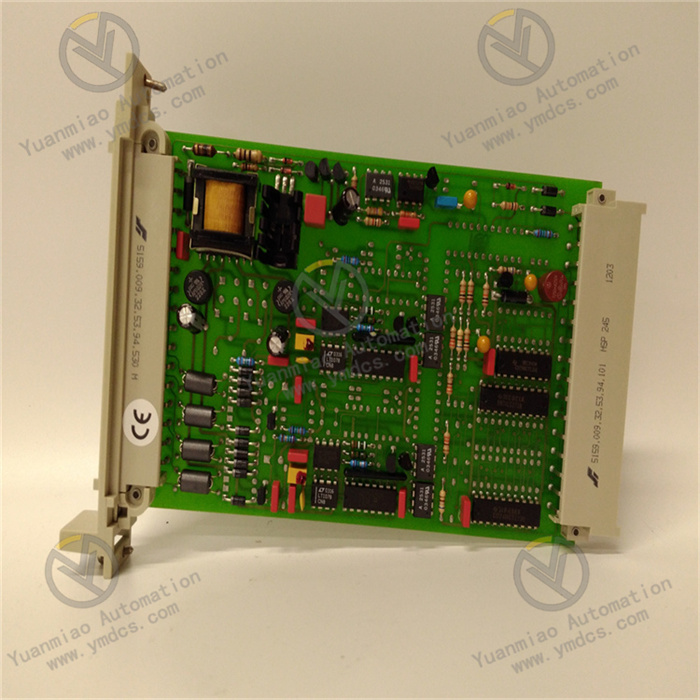

Description

Tricon system features To ensure the integrity of the system at all times, Tricon has the following features: - Provides a triple module redundancy structure where three identical sub-circuits independently perform the degree of control. There is also a dedicated hardware/software structure to "vote" on inputs and outputs. - Withstand harsh industrial environments. - Can be installed on site, and can be installed and repaired online at the module level without disrupting onsite cables. - Supports up to 118 I/O modules (analog and digital) and optional communication modules that can be connected to Modbus master and slave stations. Or connect Foxboro to Honeywell Distributed Control Systems (DCS), other Tricons within Peer-to-Peer networks, and external hosts over TCP/IP networks. - Can support remote I/O modules located up to 12 km (7.5 mi) away from the main frame. - Complete the development and debugging of the control program by using programming software based on WINDOWS system. - Intelligent functions in the input and output modules to reduce the workload of the main processor. Each I/O module has three microprocessors. The input module's microprocessor filters and repairs the input and diagnoses hardware failures on the module. The output module microprocessor provides information for the voting of the output data, checks the validity of the output status by the feedback loop voltage at the output, and can diagnose problems with the field line. - Provide comprehensive online diagnostics with repair capabilities. - Routine maintenance can be performed while Tricon is operating normally without interrupting the control process. - Provides hot backup for I/O modules in critical situations where services cannot be provided in a timely manner.

System configuration

Specifically, a basic Tricon high-density system consists of the following components: modules, racks housing each module, field terminal boards, and programming workstations. This section briefly describes these major components and their specifications.

Triconex safety system. As a leading provider of safety instrumentation systems (SIS), we provide solutions to protect people, surrounding communities and the environment while keeping production safe and operating continuously throughout the life cycle of an asset.

Tricon systems are essential for customers who need to maximize asset security and performance. If you are faced with the challenge of reducing investment and lifecycle costs, meeting new safety standards, and responding to the pressures of fierce competition in the market, as well as employee well-being and the environment, Tricon systems are for you.

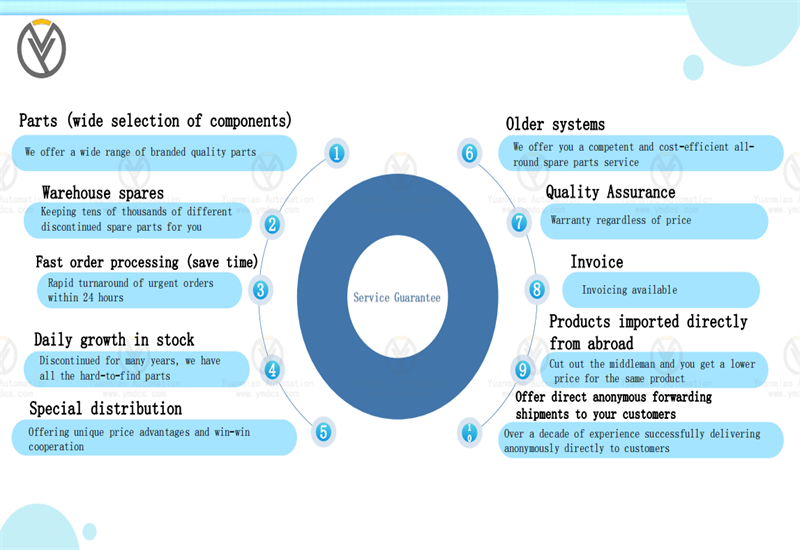

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers Company advantage: Supply imported original products, professional production of spare parts One year warranty, fast delivery time, complete supply !!! ① 24 hours email response (12 hours); ② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Triconex/