Description

Integrated Graphical Front Panel HMI Screen • Multilingual screens including Chinese for easier operator use, diagnosis and control • Large screen allows easy navigation and icon view of parameters and performance • Real time trending locally viewable by operators and engineers • Graphic steam map with current operating point view for extraction and admission • Configurable tag names to easily identify connections • Internal “Turbine Simulator” for off-line training and advance testing before system changes Improved Communications • Ethernet communications for connectivity to plant DCS, service tools and RemoteView operator control panels • Distributed I/O (LinkNet-HT) enables expanded control of additional turbine package equipment startup and control • CANOpen actuator connectivity for Woodward VariStroke actuators and DSLC-II power management networks Intelligent / Adaptive Control Algorithms • Next generation advance load rejection performance • 3 critical speed avoidance bands • Reverse rotation sensing and alarm • OptiTune adaptive PID technology for optimum set-up of turbine performance • Acceleration PID that limits overshoots for a stable and efficient plant startup • High speed data logs monitoring turbine operation and stress including run time and first out trip information • Vibration monitoring for protection and control (Sensor kit 8928-7482) Improved Service/User Tools • Cyber compliant password enabled logins • RemoteView (8928-5311) program enables virtual monitor and control from a remote workstation or mobile device • Control Assistant service tool enabled to easily configure, save, compare and view settings and data logs

8200-1312 Technical Specifications

| Analog Input | 4-20 mA channels (with Loop Power) |

| Enclosure Type | IACS UR E10 (Commercial Marine) |

| Features | ATEX, IP-54, and Pollution Degree 3 |

| Input Voltage | LV 18-36 VDC isolated |

| Operating Temperature | -22 - 158 F |

| Screen Size | 8.4in LCD |

| Storage Temperature | -22 - 158 F |

The 8200-1302 is one of several Woodward 505 Digital Governors available for the control of steam turbines. This operator control panel acts as a graphical interface and keypad that allows for adjustments to and communication with the turbine. This can be configured through Modbus communication ports located on the unit.

The 8200-1302 has multiple features available:

• Auto start sequencing for hot and cold starts, with temperature input options

• Critical speed avoidance on three-speed bands

• Ten external alarm inputs

• Ten external DI trip inputs

• Trip indication for Trip and Alarm events with associated RTC time stamp

• Dual Speed and Load Dynamics

• Peak Speed Indication for Overspeed Trip

• Zero Speed Detection

• Remote droop

• Frequency dead-band

The unit also offers three normal operating modes, including configuration, operation, and calibration modes.

The unit includes two redundant speed inputs that can accept magnetic pickup units, eddy current probes, or proximity probes. It has analog inputs (8) that can be configured for any of twenty-seven functions. The unit also has an additional twenty contact inputs. The first four of these contacts default for shutdown raise speed setpoint, reset, and lower speed set point. The others can be configured as needed. Additionally, the unit has two 4-20 mA control outputs and eight Form-C relay contact outputs.

The 8200-1302’s front panel includes an emergency trip key, a backspace/delete key, a shift key, as well as view, mode, ESC, and home keys. It also has navigation cross keys, soft key commands, and four LEDs to relate the status of control and hardware.

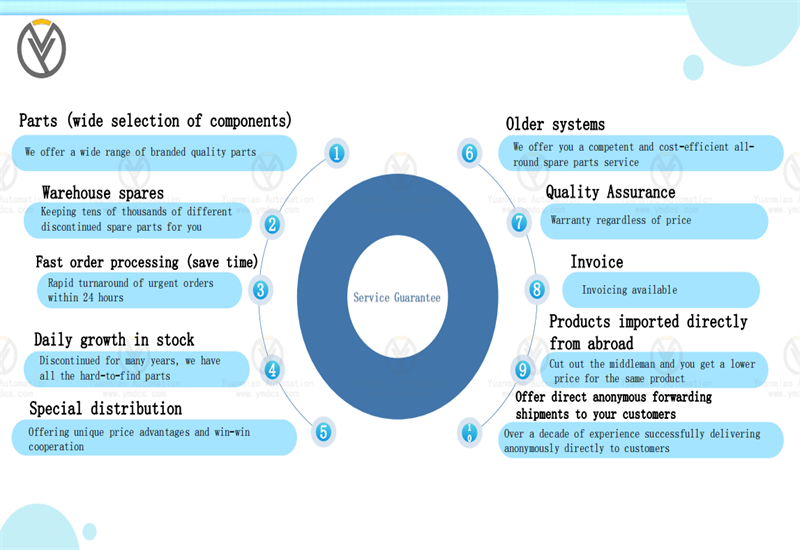

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

WOODWARD Related Products

| WOODWARD 5464-334 | WOODWARD 5464-550 |

| WOODWARD 5464-335 | WOODWARD 5464-554 |

| WOODWARD 5464-337 | WOODWARD 5464-555 |

| WOODWARD 5464-768 | WOODWARD 5464-596 |

| WOODWARD 5464-827 | WOODWARD 5464-643 |

| WOODWARD 5464-828 | WOODWARD 5464-645 |

| WOODWARD 5464-829 | WOODWARD 5464-646 |

| WOODWARD 5464-830 | WOODWARD 5464-647 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Woodward/