Description

The MVI69E-MBS is a Modbus serial enhanced communication module that can be applied to a compatible CompactLogix platform. This module has been created by ProSoft technology. This module enables connections between the CompactLogix or MicroLogix processors and the Modbus protocol devices. It acts as an input and output communication module between these 2 kinds of devices and it has the ability to store databases full of information. The ProSoft technology MVI69E-MBS Modbus serial enhanced communication module has a power consumption of 500 milliamps at 5 Volts DC. The ProSoft technology MVI69E-MBS Modbus serial enhanced communication module fits in a single slot and once it is installed it is recognized as an input and output module, and this gives it access to the processor memory. The ProSoft technology MVI69E-MBS Modbus serial enhanced communication module can operate at a specific temperature range of 0 to 60 degrees Celsius and a relative humidity range of 5 to 95% without condensation. This module provides LED indicators for 4 options such as the “module OK” status, backplane activity, Ethernet port activity, and the configuration activity. The packaging of the ProSoft technology MVI69E-MBS Modbus serial enhanced communication module includes the module itself, a male adapter cable (RJ45 to DB9), a screw terminal adapter (DB9 female to 9-pin screw terminal), and an Ethernet cable.

Features and Benefits • Supports CompactLogix processors with 1769 I/O bus capability version 16 and greater (MicroLogix 1500 not supported) • Add-on Instruction creates UDTs, providing logical definitions for I/O, status, and control data • Add-on Profile support, improving integration in the CompactLogix System • Diagnostic data available in processor controller tags, enabling decisions to be made based upon node health • Module configuration backed up in CompactLogix project (ACD file) • Module acts as a co-processor reducing impact to PLC scan time • Supports up to 10,000 words of data • Supports up to 250 Modbus Commands per port • Each port can be configured individually as a Modbus Master or Modbus Slave device • Supports Enron and Daniel-style Floating point data implementations • Suitable for SCADA and field device interface applications

Specifications

Configuration | ProSoft Configuration Builder | |

I/O Size | 60/120/240 - 16 bit integers | |

Communication | Baud Rate: 110 to 115K baud | |

Modbus Modes | RTU mode (binary) with CRC-16 | |

Floating Point | Floating point data movement supported, including configurable support for Enron, Daniel®, and other implementations | |

Modbus Function | 1: Read Coil Status | 15: Force (Write) Multiple Coils |

Modbus Master | ||

Command List | Up to 250 command per Master port, each fully configurable for function, slave address, register to/from addressing and word/bit count. | |

Polling of command list | Configurable polling of command list, including continuous and on change of state. | |

Status Data | Error codes available on an individual command basis. A slave status list is maintained per active Modbus Master port. | |

Modbus Slave | ||

Node Address | 1 to 247 (software selectable) | |

Status Data | Error codes, counters and port status available per configured slave port | |

Hardware

Specification | Description | |

Dimensions | Standard 1769 Single-slot module | |

Current Load | 500 mA max @ 5 VDC | |

Operating Temp. | 32° F to 140° F (0° C to 60°C) | |

Storage Temp. | -40° F to 185° F (-40° C to 85° C) | |

Relative Humidity | 5% to 95% (with no condensation) | |

LED Indicators | OK - Module Status | |

Debug Port | 10/100 Ethernet Port (auto-negotiating) | |

App Ports (P1,P2) | RS-232, RS-485 or RS-422 | |

Shipped with Unit | 2 - RJ45 to DB-9M cables for application ports | |

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

The company focuses on DCS, PLC, robot, large servo four systems

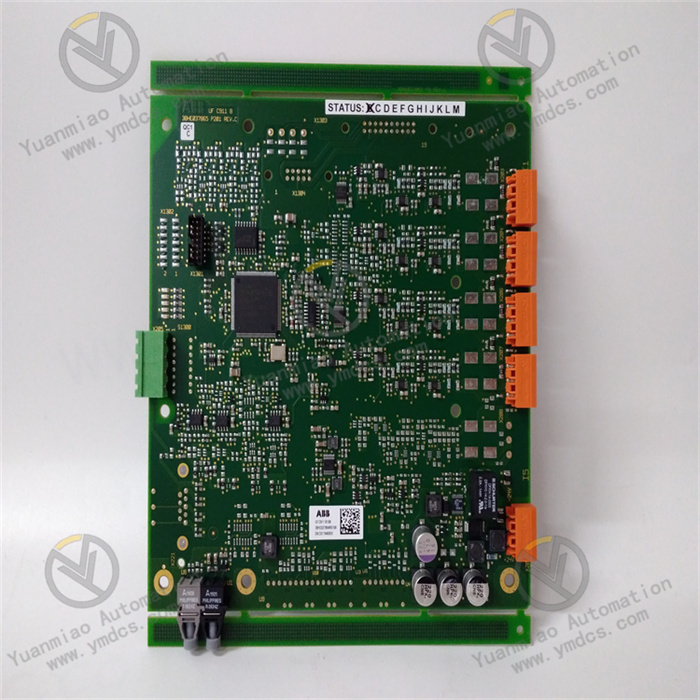

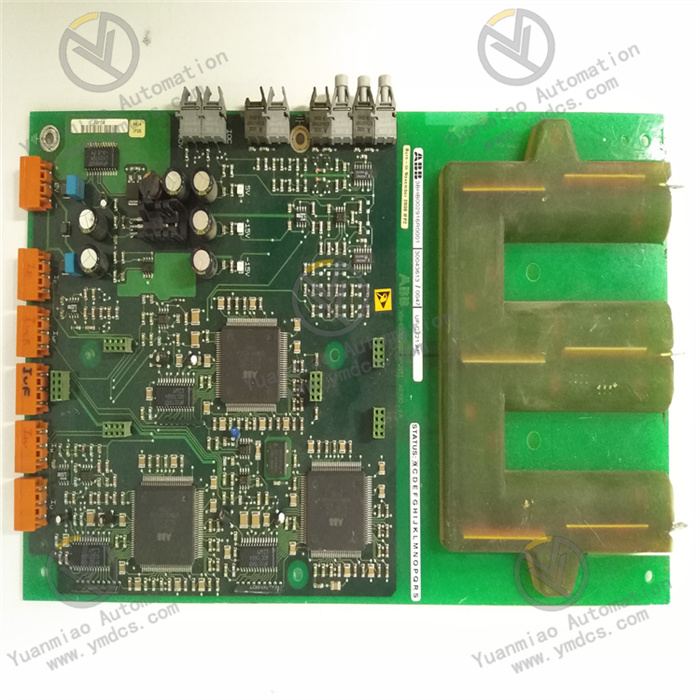

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

Allen-Bradley Related Products

| 1747-ACNR15 | 1756-L55 |

| 1747-ASB | 1756-L55M13 |

| 1747-BA | 1756-L55M14 |

| 1747-C10 | 1756-L55M16 |

| 1747-CP3 | 1756-L55M23 |

| 1747-DCM | 1756-L55M24 |

| 1747-FC | 1756-L61 |

| 1747-L511 | 1756-L61S |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:https://www.ymdcs.com/Prosoft/