Description

The PPC-R22.1N-T-Q2-G2-NN-FW is a RECO CNC module from Bosch Rexroth. This module has a design code of 2. Its power supply connection makes use of a cable with a 0.75mm2 to 1.5mm2 cross-section based on current requirements. The product is likely to have a high discharge current and high voltage during operation. The device must be installed only in commercial machinery. It should be started only if the machine that it is installed on, adheres to the national standards and regulations on safety, as well as other safety specifications. The module must be operated and repaired only by qualified and trained staff.

The safety conductor of the CNC module should always be firmly and permanently connected to the supply mains. The housing of the product becomes very hot while operating and must not be touched to avoid burns. The emergency stop switch must be mounted in a position that can easily be accessed by the operator. The device should not be disassembled or opened in a pressurized state. The unit features an H1 LED display at its top. Its module rack cannot be used to control I/O modules. The product must be installed only after the module rack is mounted. The module rack should be engaged on a DIN TS top hat rail of size 35 x 27 x 15mm and secured in position with a locking screw. The CNC module weighs 1.3kg. The device functions between a temperature range of 0°C and +45°C without reduced performance. The 24VDC power supply has a tolerance limit of -15% or +20% according to EN 61131-2 specifications. The product features one ready-for-operation relay to assist in system monitoring. The relay has a minimum lifetime of 500,000 switch cycles when it is protected against excess current. The module can be shipped with a warranty of one year to your preferred address.

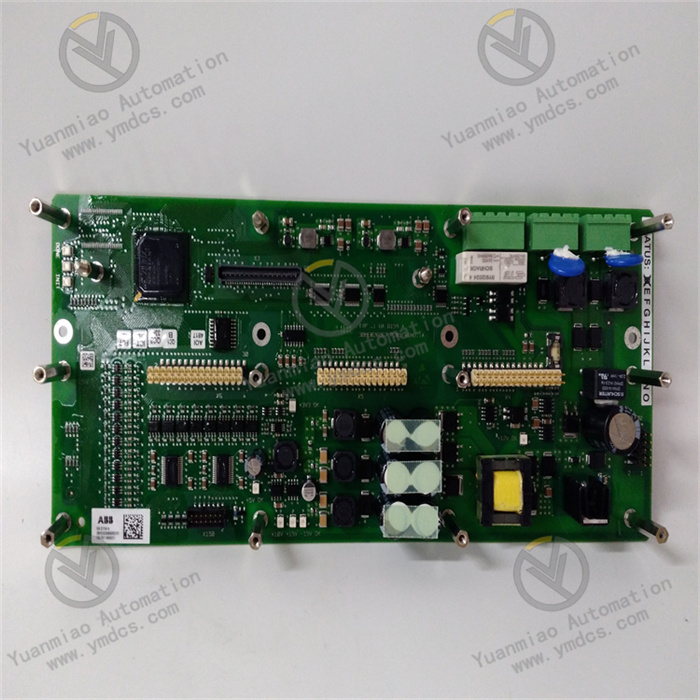

The servo driver, also known as the servo amplifier or amplifier, is a device that outputs the pulse signal or analog signal input from the controller to the motor after internal calculation and amplification. Structure and principle The servo driver is composed of servo control unit, power drive unit and communication interface unit. The servo control unit includes position controller, speed controller, torque controller and current controller. The servo driver can be divided into two modules, the power board and the control board, which are relatively independent in function. The power board is the strong current part, which includes two units, one is the power drive unit IPM used to drive the motor, and the other is the switching power supply unit to provide digital and analog power for the entire system. The control board is the weak current part, the control core of the motor and the operating carrier of the core control algorithm of servo drive technology. The control board outputs PWM/PFM signal through the corresponding algorithm, which is used as the drive signal of the drive circuit to change the output power of the inverter, so as to achieve the purpose of controlling the AC servo motor.

Drive control mode

(1) PWM control (Shadik driver)

PWM control technology: control the on-off and off-off of semiconductor switching devices, so that the output end can get a series of pulses with equal amplitude and unequal width, and use these pulses to replace sine waves or other required waveforms. By modulating the width of each pulse according to certain rules, the output voltage of the inverter circuit can be changed, and the output frequency can be changed.

Advantages:

1) Low noise;

2) High efficiency at full load and can work in continuous conduction mode;

3) The ripple voltage is small;

4) The switching frequency is fixed, so the noise filter design is easier and the noise elimination is simpler;

5) The control method is easy to implement.

Cons:

1) Due to the influence of the error amplifier, PWM loop gain and response speed are limited, PFM has a fast response speed;

2) PWM is less efficient at low load.

3) PFM control (Panasonic Drive)

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:https://www.ymdcs.com/Rexroth/