Description

The VEP40.3CEN-256NN-MAD-128-NN-FW is a 12.1” pc-based dedicated TFT display HMI panel in the IndraControl VEP40 series by Bosch Rexroth. This panel utilized a standard 600 MHz Celeron M processor, and a standard Windows CE 4.2 operating system. It features two (2) compact flash (CF) sockets, a 128 MB flash size and an application memory of 256 MB. Also, it has only one memory slot. The VEP40.3CEN-256NN-MAD-128-NN-FW comes with a Super VGA display, with a resolution of 800 x 600. Its approximate weight is 3.8 kgs and permissible humidity level is between 5 … 85 percent. The maximum value of its input current is 1.5 Amps and maximum inrush current is 7 Amps. The VEP40.3CEN-256NN-MAD-128-NN-FW is a touch screen device and features an integrated virtual keyboard. It has one (1) standard RS232 and two (2) USB 2.0 ports. The voltage supply has a value of DC 24 volts, and it doesn’t come with a short-time Uninterrupted Power Supply for data backup on the CF. The overall design of the VEP40.3CEN-256NN-MAD-128-NN-FW conforms with the IP 20 protection category, and its embedded front panels conform with the IP 65 protection class. The input power rating of this model of the VEP40 HMI operator panel is 53 W. The min. and max. voltage of the VEP40.3CEN-256NN-MAD-128-NN-FW is rated for DC 19 V and DC 30 V. When operating this display panel, the acceptable temperature is within 5 degrees C to 45 degrees C. The VEP40.3CEN-256NN-MAD-128-NN-FW is robust, cost-effective and more efficient than traditional PC-type operator panels. During installation and commissioning, do not mount this equipment in areas exposed to sunlight and UV light, to prevent the reduction in screen readability.

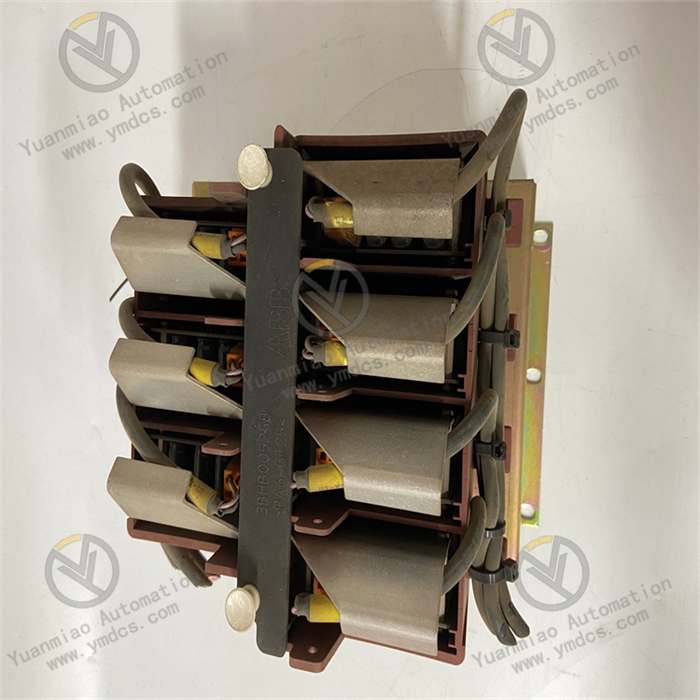

The servo driver, also known as the servo amplifier or amplifier, is a device that outputs the pulse signal or analog signal input from the controller to the motor after internal calculation and amplification. Structure and principle The servo driver is composed of servo control unit, power drive unit and communication interface unit. The servo control unit includes position controller, speed controller, torque controller and current controller. The servo driver can be divided into two modules, the power board and the control board, which are relatively independent in function. The power board is the strong current part, which includes two units, one is the power drive unit IPM used to drive the motor, and the other is the switching power supply unit to provide digital and analog power for the entire system. The control board is the weak current part, the control core of the motor and the operating carrier of the core control algorithm of servo drive technology. The control board outputs PWM/PFM signal through the corresponding algorithm, which is used as the drive signal of the drive circuit to change the output power of the inverter, so as to achieve the purpose of controlling the AC servo motor.

Drive control mode

(1) PWM control (Shadik driver)

PWM control technology: control the on-off and off-off of semiconductor switching devices, so that the output end can get a series of pulses with equal amplitude and unequal width, and use these pulses to replace sine waves or other required waveforms. By modulating the width of each pulse according to certain rules, the output voltage of the inverter circuit can be changed, and the output frequency can be changed.

Advantages:

1) Low noise;

2) High efficiency at full load and can work in continuous conduction mode;

3) The ripple voltage is small;

4) The switching frequency is fixed, so the noise filter design is easier and the noise elimination is simpler;

5) The control method is easy to implement.

Cons:

1) Due to the influence of the error amplifier, PWM loop gain and response speed are limited, PFM has a fast response speed;

2) PWM is less efficient at low load.

3) PFM control (Panasonic Drive)

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:https://www.ymdcs.com/Rexroth/