Description

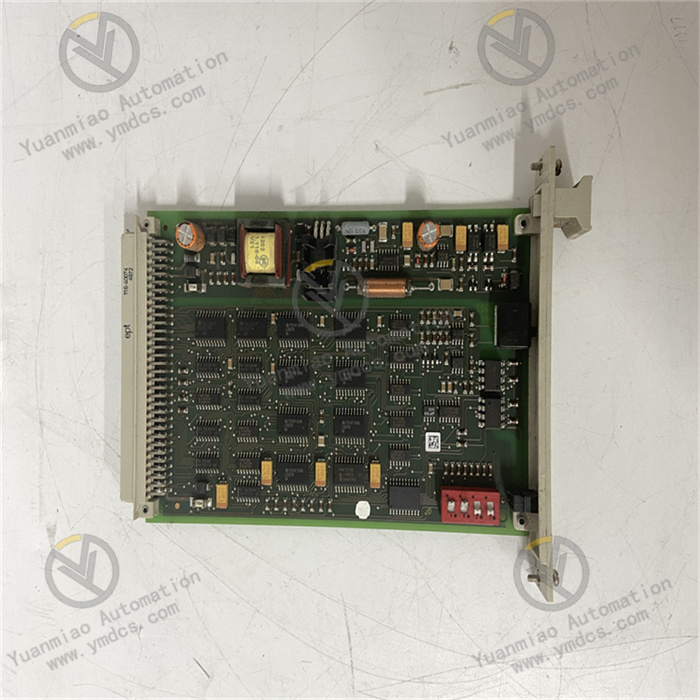

The FBM220/221 Termination Assembly (TA)provides for making H1 FOUNDATION fieldbus cableconnections to an FBM220 (single channel) orFBM221 (four channel) Fieldbus Module. It containsthe necessary FOUNDATION fieldbus wire connectionpoints, an isolated dc-to-dc converter, and busterminator(s). The FOUNDATION fieldbus wire connections (andpower supply connections) are made withcompression type screw terminals for quick, securesignal connection. The TA feeds the H1communication signals directly to the FBM220/221. The dc-to-dc converter in the TA receives 24 V dcpower from an optionally redundant external powersource. This power source can be one of the existingsupplies which power the FBM baseplates, or a usersupplied power supply. The 24 V dc power isconverted to isolated 30 V dc power (at 300 mA) forpowering the FOUNDATION fieldbus field devices.Individual switch(es) on the TA provide on/off controlof the power to each of the H1 bus segment(s). The bus terminator(s) in the TA are used when theFBM220/221 is located at the end point on theFOUNDATION fieldbus segment(s). Individualswitch(es) on the TA provide for bus terminatorselection (in or out) for each H1 segment. The TA connects to the FBM subsystem baseplate bymeans of a dedicated cable, which is available in avariety of lengths from 0.5 m (1.65 ft) to 30 m (99 ft): 0.5 m – P0916DA 3.0 m – P0916DC 1.0 m – P0916DB 5.0 m – P0916DD 10.0 m – P0916DE 15.0 m – P0916DF 20.0 m – P0916DG 25.0 m – P0916DH 30.0 m – P0916DJ

Overview of open intelligent DCS control system

I/A Series system is a new generation of open intelligent DCS control system launched by FOXBORO Company in the United States, which is the world's first industrial control system using open network. It is also the current high standard DCS control system using 64-bit workstations and full redundancy. I/A Series has been widely used in power, petrochemical, metallurgy, building materials, light industry, textile, food and other fields of the system.

The most important feature of I/A Series is openness, on the system and MIS communication layer, whether it is 51 series or 70 series, it can be very convenient to communicate with the factory information network.

I/A Series uses a standard communication protocol, we can easily communicate with the management network at a high rate of real-time and historical data, as well as real-time process operation screen. Through these real-time process data, it provides the decision basis for the decision-making level of the factory. It can make the manager clearly see the unreasonable place of the process, carry out the optimization reform of energy consumption, quality, etc., so that the management of the whole factory has been modernized to a new level. All kinds of information and data can also be transmitted bidirectional through Ethernet and TCP/IP, DECNET, NFS, X.25, NOVELL/IP and other communication protocols with various types and models of desktop computers, laptops, servers, workstations and mainframes.

The I/A Series operating environment provides plant operators with direct and intuitive access to process information, quality control information, and other system performance feedback.

Process operators can call up the process display screen through the operation station, observe the process loop parameter status, real-time trend, historical trend and alarm situation, and realize the process loop operation and parameter adjustment.

Process engineers can call up the process configuration screen through the operation station to control scheme configuration, process flow chart configuration, trend screen configuration and various report configuration.

Software engineers develop software through many convenient, practical and powerful application packages provided by the operating station system, provide interface functions with other networks, and can also develop user applications in C language.

System maintenance engineers can monitor the system status through the operation station and diagnose the system. Each operating station processor is equipped with an independent hard disk and keyboard, placing its own operating system software and process screen, which can independently operate and display the system in real time.

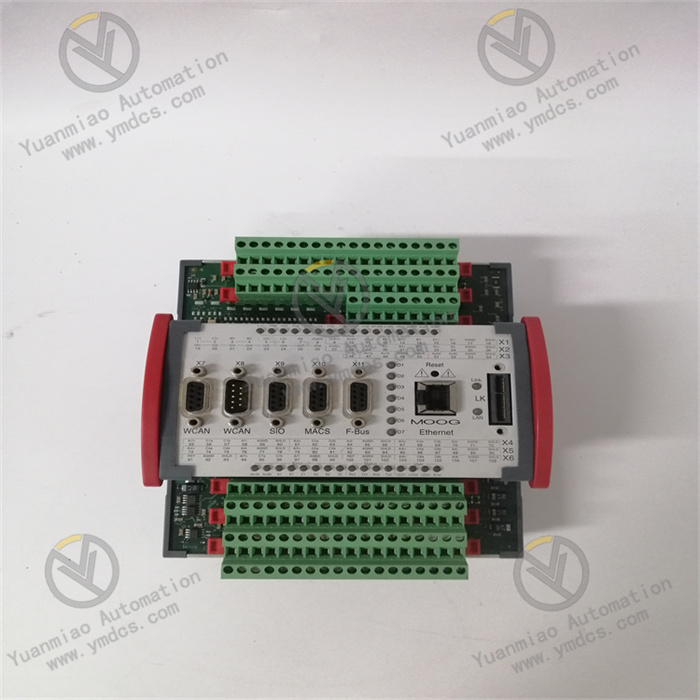

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers Company advantage: Supply imported original products, professional production of spare parts One year warranty, fast delivery time, complete supply !!! ① 24 hours email response (12 hours); ② For shipment outside Asia, please contact the seller.

Foxboro Related Products

| A4H254-8F8T | P0960JA-CP40 |

| A4H124-24FX | P0970BC-DNBI |

| A2H124-24FX | P0970EJ-DNBX |

| A4H124-24TX | P0971WV-DNBT |

| IPM02-P0904HA | P0972PP-NCNI |

| IDP10-AF1C01F | P0904HA-IPM2 |

| PO961BC-CP40B | P0961BC-CP40B |

| P0961EF-CP30B | P0961BD-GW30B |

| P0961FX-CP60S | P0400VP-CMP10 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/Foxboro/