Description

A power supply module is a power supply that can be mounted directly on a printed circuit board (see Figure 1) and is characterized by providing power for application-specific integrated circuits (ASics), digital signal processors (DSPS), microprocessors, memory, field programmable gate arrays (FPgas), and other digital or analog loads. In general, such modules are called point-of-load (POL) power supply systems or point-of-use power supply systems (PUPS). Because of the many advantages of modular structure, various modules are widely used in high-performance telecommunications, network connection and data communication systems. While there are many advantages to using modules, engineers often ignore reliability and measurement issues when designing power modules and even most on-board DC/DC converters.

Advantages of the power module At present, different suppliers have launched a variety of different power modules in the market, and the input voltage, output power, function and topology of different products are different. The use of power modules saves development time and allows products to be brought to market faster, so power modules are superior to integrated solutions. The power module also has the following advantages: Each module can be rigorously tested separately to ensure its high reliability, including power-on testing to weed out non-specification products. In contrast, integrated solutions are more difficult to test because the entire power supply system is closely linked to other functional systems on the circuit. Different suppliers can design modules of the same size according to existing technical standards, providing a variety of different options for engineers designing power supplies. ● Each module is designed and tested in accordance with standard performance requirements, helping to reduce the risk of adopting new technologies. ● If the integrated solution is used, once the power supply system has a problem, the whole host board needs to be replaced; If the modular design is adopted, the problem module can be replaced, which will help save cost and development time.

Reliability Any module must pass rigorous testing at an early stage to ensure that the design is sound and reliable, so as not to have unexpected problems at the last stage of the production process. The modules must be able to be tested in the customer's system to ensure that all relevant factors that may cause system failure, such as cooling fan failure, intermittent cooling fan pauses, etc. are fully considered. Engineers who use distributed architecture want to design systems that can last for many years with little or no failure. Since the test figures show that the MTBF of the power module is up to several million hours, it is not difficult to achieve this goal. But what is often ignored is the reliability of the printed circuit board. According to the current trend, the printed circuit board area is shrinking, but the need to deal with more and more electrical flow, so the increase in current density may cause hidden or other through holes can not perform normal functions. The printed circuit board has some hidden through holes that must transmit a large amount of current, and for these hidden through holes, there must be sufficient copper guards around them to provide protection to ensure that the design is more reliable and durable. This protective device can also inhibit the thermal expansion of the Z-axis, otherwise, if there is any change in the ambient temperature of the printed circuit board during the production process and when the product is used, the concealed through hole will be exposed. The engineer must thoroughly review the printed circuit board design with reference to the professional advice of the printed circuit board manufacturer, who can provide professional advice on the reliability of the printed circuit board design according to their production capacity.

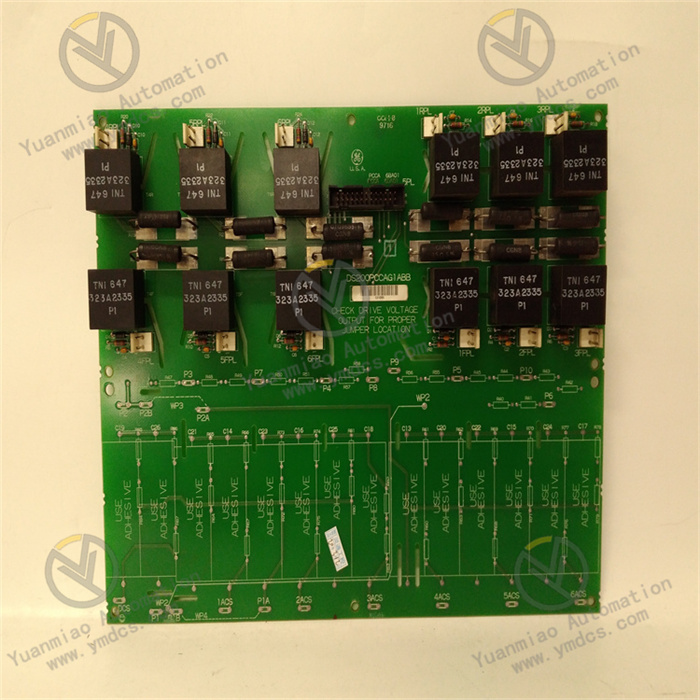

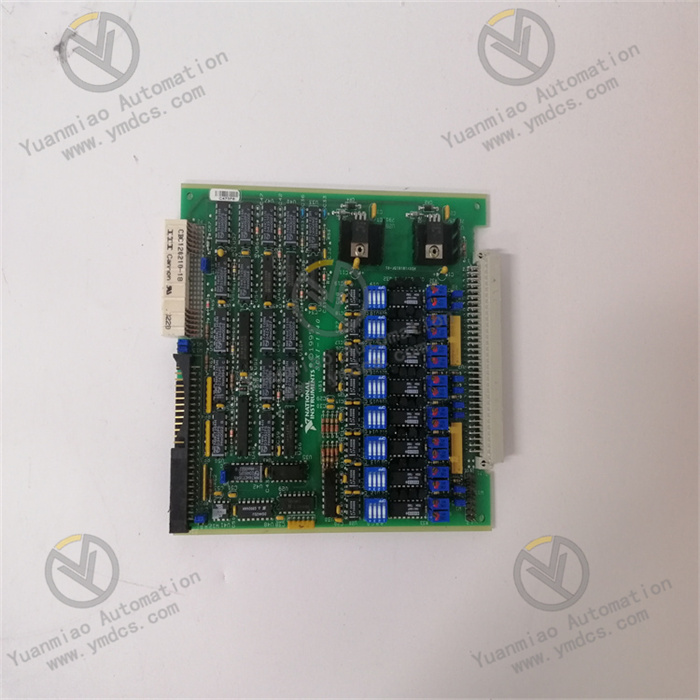

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers Company advantage: Supply imported original products, professional production of spare parts One year warranty, fast delivery time, complete supply !!! ① 24 hours email response (12 hours); ② For shipment outside Asia, please contact the seller.

Schneider Related Products

| 140EHC10500 | 140DDO85300 |

| 140EHC20200 | 140DIO33000 |

| 140HLI34000 | 140DSI35300 |

| 140MSB10100 | 140DVO85300 |

| 140NOE77101 | 140ECH10500 |

| 140NOM21100 | 140EIA92100 |

| 140NRP95400 | 140ERT85410 |

| 140NWM10000 | 140ERT85420 |

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: https://www.ymdcs.com/Schneider/