Description

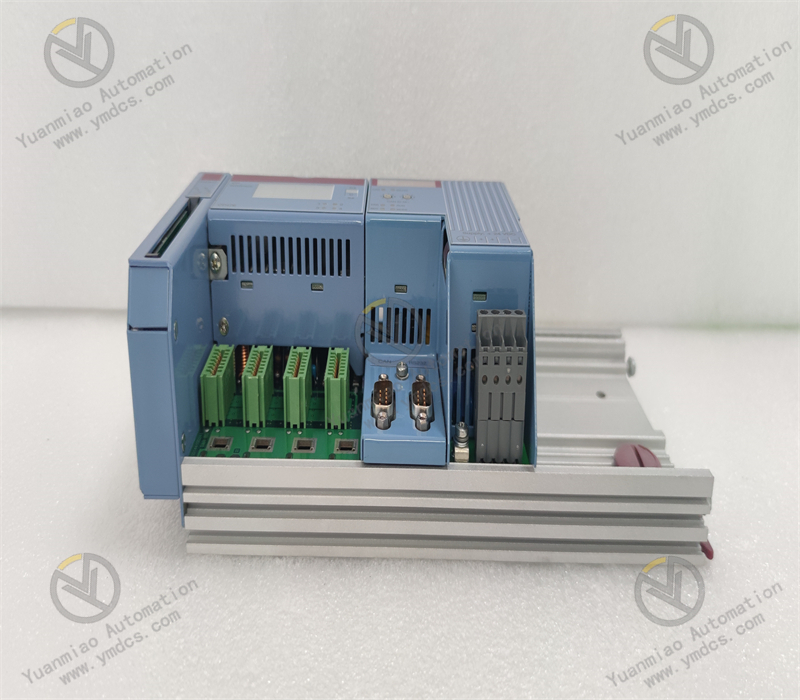

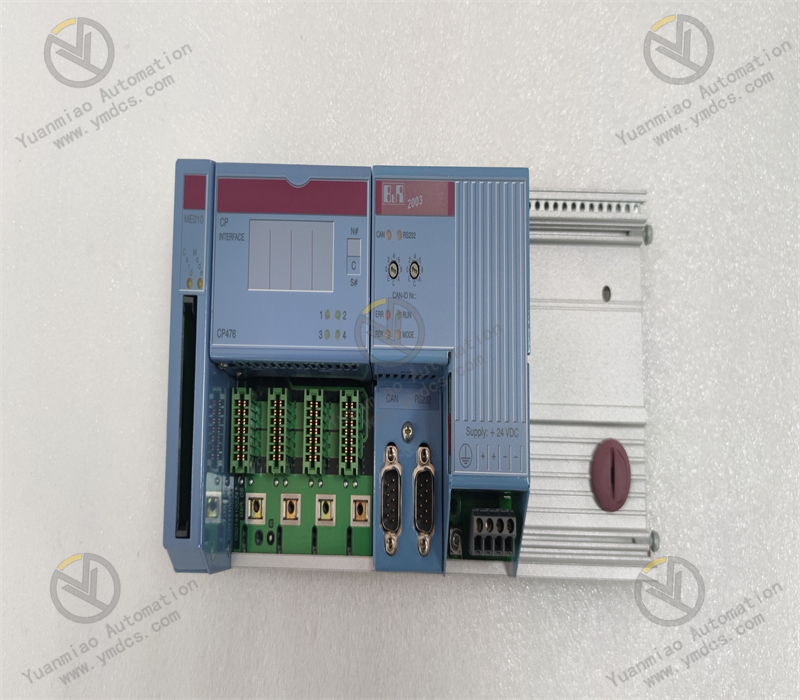

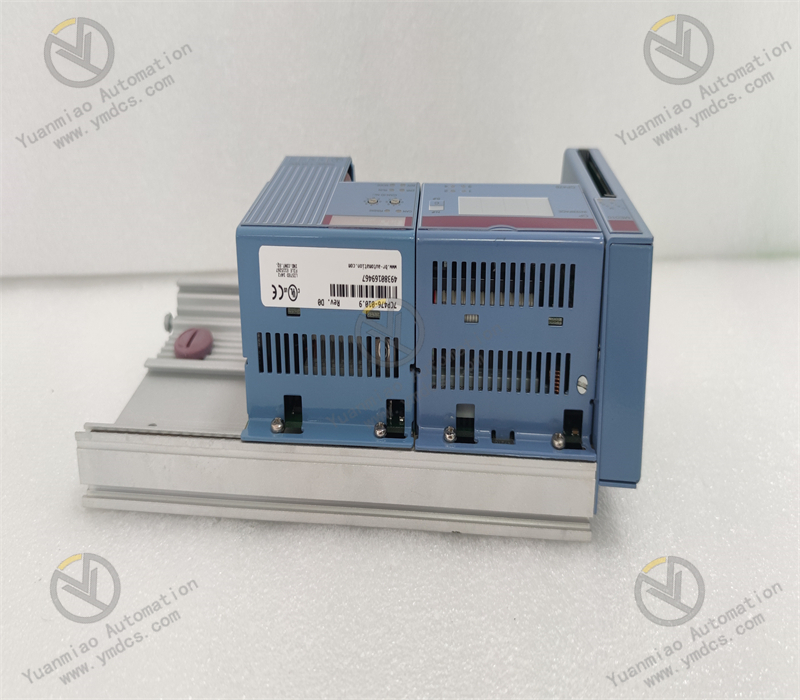

2003 CPU with expansion, 750 kB SRAM, 1.5 MB FlashPROM, 24 VDC, 12.15 W power supply, 1 RS232 interface, 1 CAN interface, CAN: Electrically isolated, network-capable, 4 slots for screw-in modules, expansion: 1 PCMCIA slot

Servo motor, according to the requirements of the control command, the power is amplified, transformed and regulated, so that the torque, speed and position control of the output of the drive device is very flexible and convenient. Because of its "servo" performance, it is named as a servo motor. Its function is to convert the input voltage control signal into the angular displacement and angular velocity output on the axis drive control object. Servo motors are generally divided into two categories: DC servo motors and AC servo motors. Ac servo motor The rotor inside the AC servo motor is a permanent magnet, and the U/V/W three-phase electricity controlled by the driver forms an electromagnetic field, and the rotor rotates under the action of this magnetic field, while the encoder of the motor comes with a feedback signal to the driver, and the driver adjusts the rotor rotation Angle according to the feedback value and the target value. When the AC servo motor has no control voltage, only the pulsating magnetic field generated by the excitation winding is in the stator, and the rotor is stationary. When there is a control voltage, a rotating magnetic field is generated in the stator, the rotor rotates in the direction of the rotating magnetic field, in the case of constant load, the speed of the motor changes with the size of the control voltage, when the phase of the control voltage is opposite, the servo motor will reverse.

Dc servo motor

The working principle of DC servo motor is basically the same as that of ordinary DC motor. Electromagnetic torque is generated by the action of armature air flow and air gap flux to make the servo motor rotate. The armature control method is usually used to change the speed by changing the voltage while keeping the excitation voltage unchanged. The smaller the voltage, the lower the speed. When the voltage is zero, stop rotating. Because when the voltage is zero, the current is also zero, so the motor will not produce electromagnetic torque, neither will there be rotation phenomenon.

Dc servo motor is widely used in numerical control system, but DC servo motor also has some disadvantages: its brush and commutator are easy to wear; The maximum speed limit of the motor, the application environment limit; The structure is complicated, the manufacture is difficult and the cost is high.

The company focuses on DCS, PLC, robot, large servo four systems

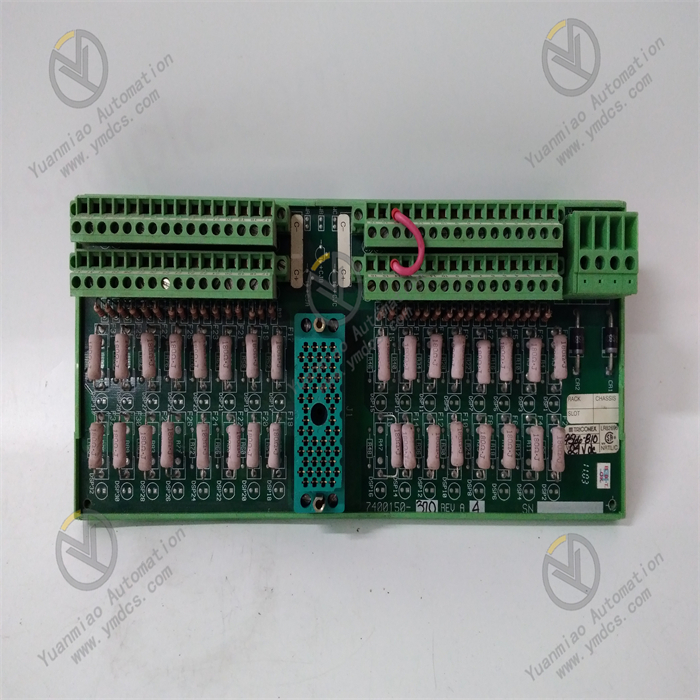

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/other_brand/