Description

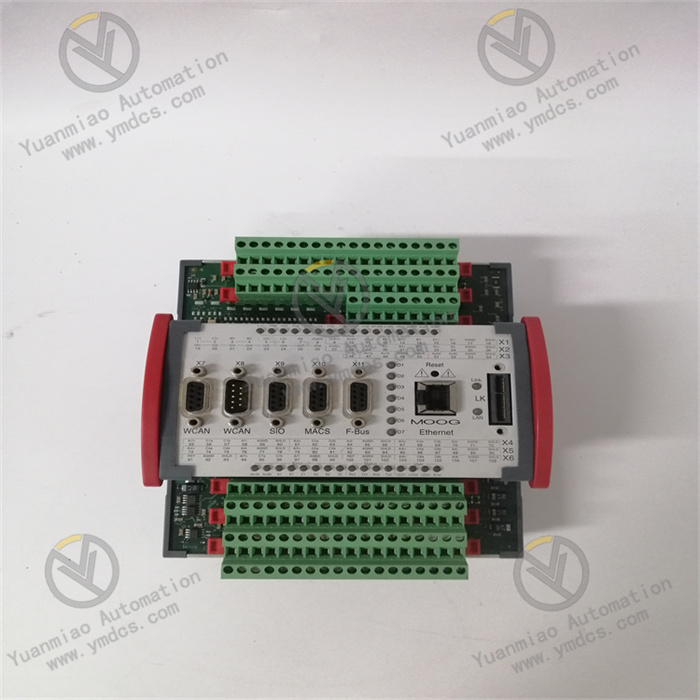

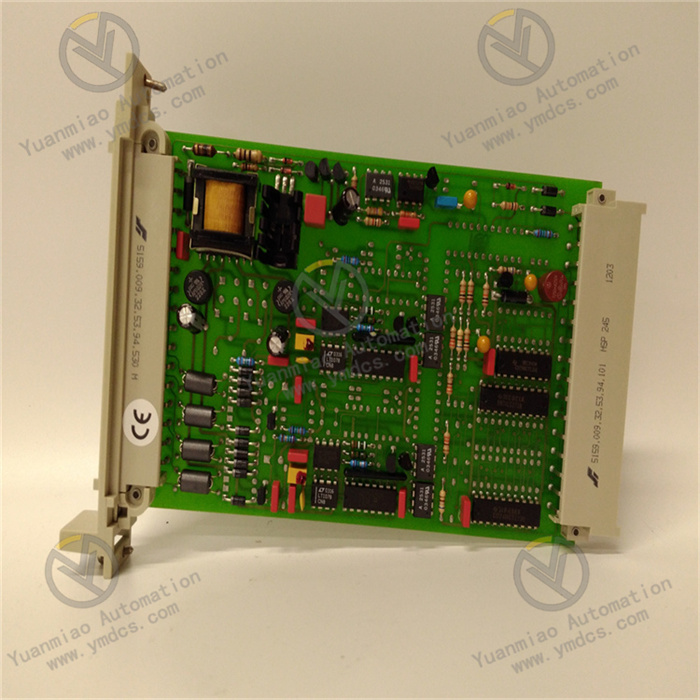

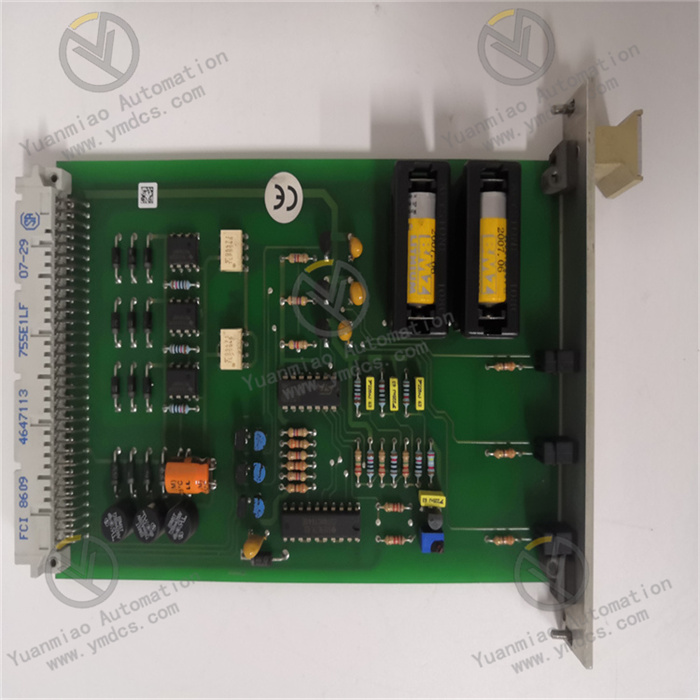

The INFO-4KP is the field bus node forhigh-precision and very fast positioning and control tasks.The board incorporates four complete, independent channels.The positioning board is a pure peripheral board, i.e. the control algorithmsrequiring much computing power areperformed by the firmware in the INFOMaster.The firmware also performs the conversion of increments into degrees,meters or mm and ensures referencetravels accurate to one increment. An INFO-PPC Master with thePowerPC RISC-CPU controlsup to 64 axes in addition toperforming the entire machine control function. The board is suitable for controllingservo controllers, frequency converters or for reading handwheels. Onboard is a DC/DC converter for resolvers and proximity switches.

Technical Data Sampling rate - Standard: 64 axes 4ms 32 axes 2ms 16 axes 1ms 8 axes 0.5ms - Ramp profiles, e.g. sine ramp. 4 incremental inputs - RS422, TTL or 15 ... 24V - max. 2.5MHz counting frequency 4 zero point inputs - RS422, TTL or 15 ... 24V - Reference travel accurate to oneincrement 4 DAC outputs - for analog controller control - ±10V with 0.3mV resolution 4 outputs - Controller enable - 24V/10mA individually isolated 5V supply - for resolver - 400mA max. 15V supply - for 4 proximity switches - 4 x 20mA max.

The position control software of theINFO-Power PC Master independentlycontrols up to 64 axes simultaneously.This software can be controlled in anyrequired programming language.The axis parameters (control weights,norm factors, preselection values, etc.)are written via the INCO-DLL into thefield bus master. The preselection valuesare indicated in the user-specific unitssuch as degrees, meters or mm.The INFO-PPC Master controls and monitors the entire ramp and constant runs,brakes to the accuracy of an increment atthe required point and maintains thispoint up to the next run command. Inaddition, the resolution of the encoder isextended by a software function by means of the four-quadrant method to 32-bit. Each axis is sampled every 500µs,and the control intervals last 4, 2, 1 or0.5ms, depending on the number of axes.Speed changes during running, multipleaxis trajectory runs (pull mode) are justas possible as premature termination orEMERGENCY OFF. Of course, it is alsoat all times possible to read the currentposition. Other modes: - Start-up mode (without faultmonitoring) - Control and simulation mode(without feedback, open-loopcontrol) - Automatic normalization (alwaysbetween 0 ... 360 degrees) - Automatic zeroing after each run - Endless turning- DAC / increment mode (pure DACoutput ±10V) and 16-bit encoderpath measurement - DAC / path mode (pure DACoutput ±10V) and path measurement with conversion to meters,mm or degrees

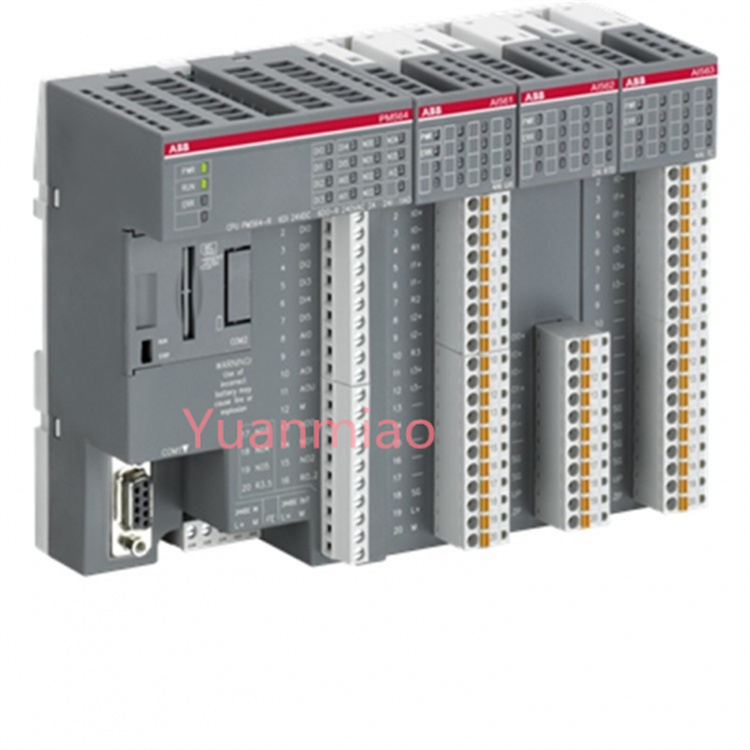

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/other_brand/