Description

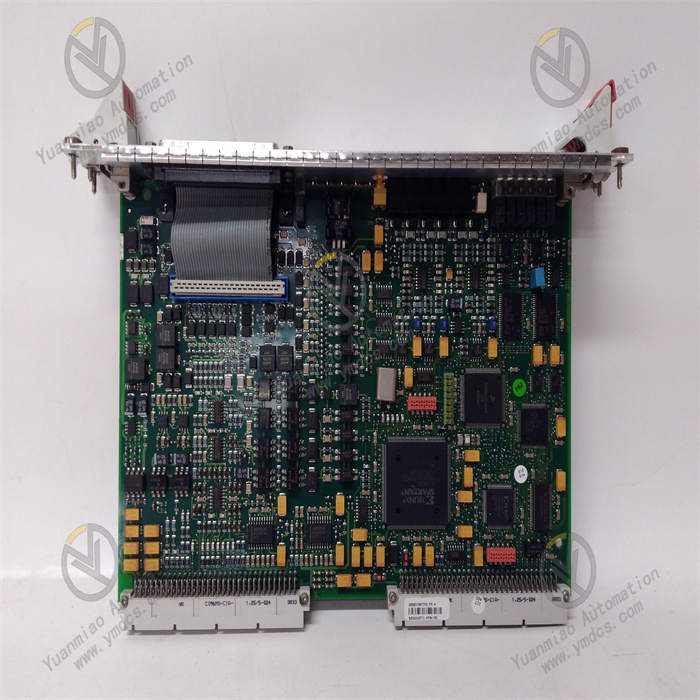

Part Number: 9907-014

Manufacturer: Woodward

Product type: Speed Control Module

Country of Manufacture: United States (USA)

Functional Description

9907-014 is a Speed Control Module developed by Woodward. It is responsible for monitoring and regulating the speed of the system it is connected to. It receives input signals, such as engine speed or process variables, and adjusts the output accordingly to maintain the desired speed setpoint. The module utilizes advanced control algorithms and feedback mechanisms to ensure accurate and responsive speed control.

System proximity probe

- To detect very low speeds, a proximity probe can be used. A proximity probe can detect speed down to 0.5 Hz. A pull-up resistor is required between the supplied proximity probe voltage and the proximity probe input to the FTM when interfacing to open collector type proximity probes. Each speed input to power system proximity probes includes individually fused 12 Vdc and 24 Vdc sources (100 mA fuses, located on the FTMs, are used). When interfacing with an open collector type proximity probe, external pull-up resistors are required.

Channel 1 depicts an MPU connection, Channel 2 a 24 V proximity connection, and Channel 3 a 12 V proximity connection. When connecting a proximity probe, always jumper the unused MPU connection to eliminate potential noise interference.

System Features

- Together with Woodward's GAPTM Graphical Application Program, the MicroNet Operating System creates a powerful control environment. Woodward's one-of-a-kind rate group structure ensures that control functions run deterministically at rate groups defined by the application engineer.

- Control loops that are critical can be processed in 5 milliseconds. Slower rate groups are typically assigned less critical code. The rate group structure prevents the addition of new code from changing system dynamics. Control is deterministic and predictable at all times.

- For key control signals, synchronized inputs and outputs (I/O) are available, while distributed I/O can be used for other less critical parameters. The MicroNet platform supports a variety of communication methods for programming and servicing the control, as well as interacting with other systems (Plant DCS, HMI, etc.).

- Application code is generated using Woodward's GAP and Ladder Logic programming tools. The user can view and tune system variables via a service interface. There are several tools available to provide this interface. TCP/IP, OPC, Modbus, and other current designs are included in order for the user to correctly interface the control to existing or new plant level systems.

Product Features

- Speed Sensing: Interfaces with speed sensors that monitor the turbine's current rotational speed. These sensors can be optical, magnetic, or based on other technologies, depending on the type of turbine and the environmental conditions.

- Reference Speed Setting: The operator or control system sets a reference speed, which is the desired or target speed at which the turbine should operate. The SCM compares this reference speed with the actual speed from the sensors.

- Control Algorithm: Uses a control algorithm to calculate the necessary adjustments required to bring the turbine's speed in line with the reference speed. This algorithm considers various factors such as load changes, external disturbances, and the turbine's response characteristics.

- Communication Interface: IIt have communication interfaces to exchange data with a central control system, allowing for remote monitoring, diagnostics, and control adjustments.

- Integration with Other Control Systems:Interfaces with other control modules responsible for functions such as load control, temperature control, and vibration monitoring to ensure overall turbine system stability and efficiency.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

The company focuses on DCS, PLC, robot, large servo four systems

The main products are various modules/cards, controllers, touch screens, servo drivers

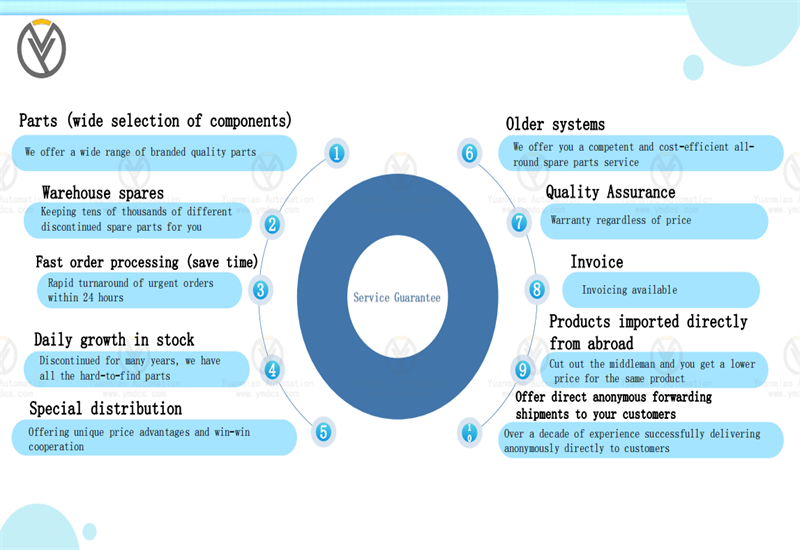

Company advantage: Supply imported original products, professional production of spare parts

One year warranty, fast delivery time, complete supply !!!

① 24 hours email response (12 hours);

② For shipment outside Asia, please contact the seller.

WOODWARD Related Products

| WOODWARD 5462-443 | WOODWARD 9904-263 |

| WOODWARD 5462-472 | WOODWARD 9905-001 |

| WOODWARD 5462-482 | WOODWARD 9905-017 |

| WOODWARD 5462-518 | WOODWARD 9905-020 |

| WOODWARD 5462-519 | WOODWARD 9905-021 |

| WOODWARD 5462-520 | WOODWARD 9905-059 |

| WOODWARD 5462-521 | WOODWARD 9905-089 |

| WOODWARD 5462-522 | WOODWARD 9905-144 |

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Woodward/