Description

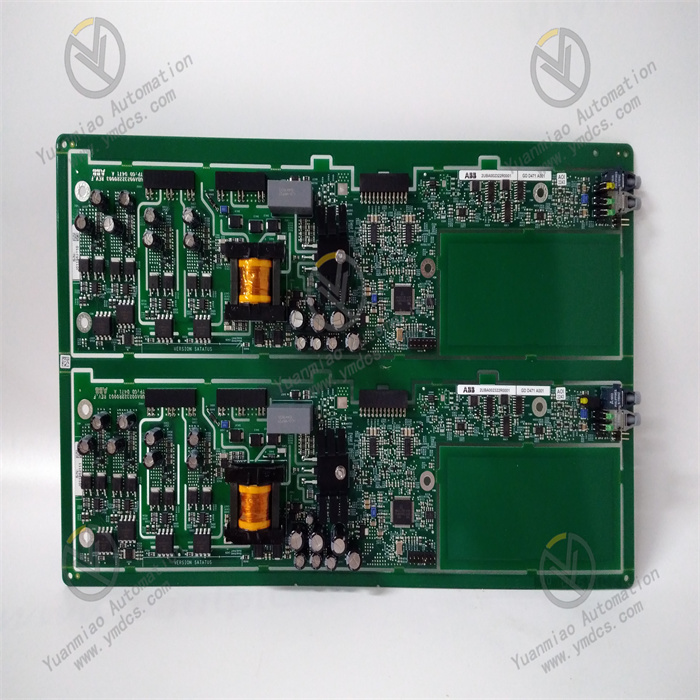

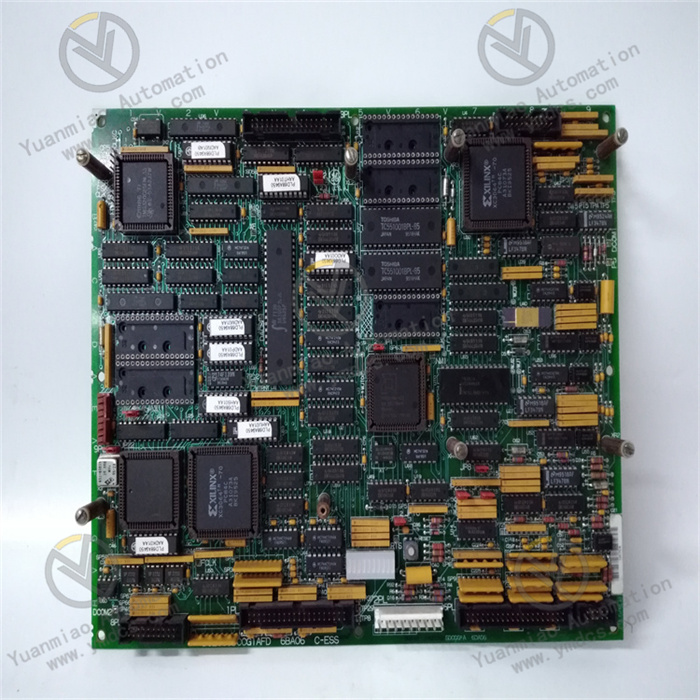

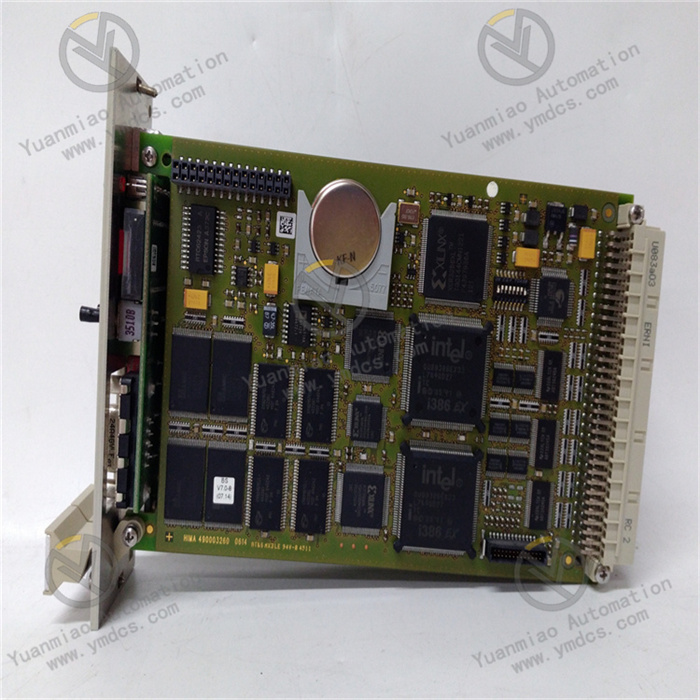

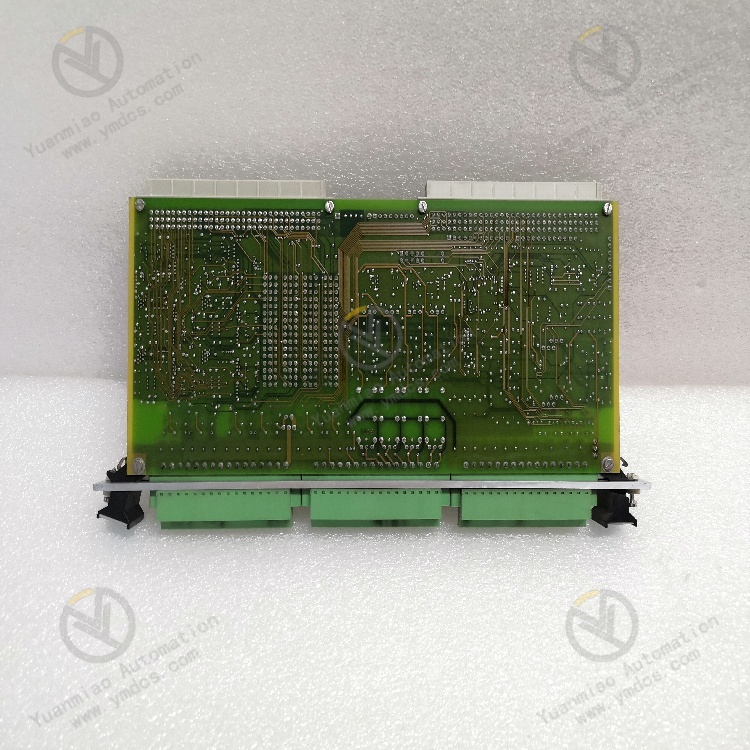

The VIBRO-METER VM600 IOC4T is an input/output card of the VM600 series Mechanical Protection System (MPS), and 200-560-000-016 and 200-560-101-01 are its relevant product numbers.

Features: Rich Signal Interfaces: It is a signal interface card with 4 dynamic signal input terminals and 2 tachometer (speed) input terminals, used for the MPC4 mechanical protection card. It can connect to a variety of sensors, providing comprehensive signal inputs for the mechanical protection system. Relay Function: It contains 4 relays, which can be used for alarm signals under software control. For example, it can send out MPC4 fault signals or problem signals detected by common alarms. Flexible Output: It has 32 fully programmable open-collector outputs (jumpers are optional), which can be connected to the IRC4 and RLC16 relay cards, facilitating the implementation of various control logics. Signal Processing and Protection: It provides EMI protection for all inputs and outputs to ensure the stability and accuracy of signals; it has a filtering function, complies with the Electromagnetic Compatibility (EMC) standard, and can prevent electromagnetic interference. Hot Swap: It supports hot swap, that is, the function of plugging and unplugging in real time. It is convenient to carry out maintenance and replace the card during the operation of the system without shutting down, reducing the system downtime. Multiple Versions Available: It provides "standard" and "independent circuit" versions, which can be selected according to different application scenarios and requirements. This module is suitable for modern industrial fields such as power, petroleum, mines, ports, etc. In these industries, it can be used in combination with the MPC4 mechanical protection card to monitor and protect the status of various mechanical equipment, promptly detect problems such as abnormal vibrations and speed changes during the operation of the equipment, and prevent equipment failures and accidents.

When installing the VIBRO-METER VM600 IOC4T, in order to ensure its normal operation and the safety of the equipment, the following aspects need to be noted: 1. Environmental Requirements Temperature and Humidity: The temperature and humidity of the installation environment need to meet the specified range of the equipment. Generally speaking, installation in an environment with too high or too low temperature (such as exceeding 0°C - 50°C) and high humidity (relative humidity exceeding 80%) should be avoided, otherwise it may affect the performance and service life of the equipment. Electromagnetic Interference: Keep away from strong electromagnetic interference sources, such as large motors, transformers, high-frequency equipment, etc. Strong electromagnetic interference may cause abnormal signal transmission of the IOC4T card, affecting the measurement and control accuracy. Dust and Corrosive Gases: Keep the installation environment clean and avoid the accumulation of a large amount of dust. At the same time, the equipment should be prevented from being exposed to an environment containing corrosive gases (such as sulfur dioxide, chlorine, etc.) to prevent the corrosion of the electronic components of the equipment.

2. Installation Location Rack Selection: Select a suitable VM600 rack to ensure that the rack has enough space and slots to install the IOC4T card. The rack should have good mechanical strength and stability to support the weight of the equipment and prevent the impact of vibrations on the equipment. Ventilation and Heat Dissipation: Ensure that there is good ventilation in the rack to avoid overheating of the equipment due to poor heat dissipation. The IOC4T card should be installed in a well-ventilated position in the rack, maintaining an appropriate distance from other heat-generating equipment.

3. Installation Operation

Power-off Operation: Before installing the IOC4T card, make sure that the entire VM600 system has been powered off to prevent electric shock and equipment damage.

Electrostatic Protection: Wear an anti-static wristband or take other anti-static measures to avoid damage to the electronic components caused by static electricity. During the operation process, try to avoid directly touching the electronic components on the card.

Proper Insertion: Insert the IOC4T card accurately into the rear slot of the VM600 rack, ensuring a tight connection between the card and the slot and avoiding looseness. Pay attention to the direction and position of the card during insertion and operate according to the instructions in the manual.

Firm Fixation: Use appropriate fixing devices (such as screws) to firmly fix the IOC4T card on the rack to prevent the card from loosening or falling off during operation.

3. Installation Operation

Power-off Operation: Before installing the IOC4T card, make sure that the entire VM600 system has been powered off to prevent electric shock and equipment damage.

Electrostatic Protection: Wear an anti-static wristband or take other anti-static measures to avoid damage to the electronic components caused by static electricity. During the operation process, try to avoid directly touching the electronic components on the card.

Proper Insertion: Insert the IOC4T card accurately into the rear slot of the VM600 rack, ensuring a tight connection between the card and the slot and avoiding looseness. Pay attention to the direction and position of the card during insertion and operate according to the instructions in the manual.

Firm Fixation: Use appropriate fixing devices (such as screws) to firmly fix the IOC4T card on the rack to prevent the card from loosening or falling off during operation.

4. Wiring Connection Cable Selection: Select appropriate cables for connection according to the signal type and transmission distance. For the transmission cables of sensors and signal conditioners, shielded cables should be used to reduce electromagnetic interference. Proper Wiring: Connect the input and output signals of the IOC4T card correctly according to the wiring diagram and the requirements of the manual. Ensure that the wiring is firm and avoid loose connections or short circuits. For the power supply wiring, pay attention to the matching of the voltage level and polarity. Terminal Tightening: Use tools such as a screwdriver to connect the cables to the screw terminal connectors and ensure that the terminals are tightened to prevent the signal transmission from being interrupted due to loose cables.

5. Inspection and Testing

Post-installation Inspection: After the installation is completed, carefully check whether the installation and wiring of the IOC4T card are correct, and whether there are any loose or incorrectly connected parts.

Power-on Test: After confirming that the installation and wiring are correct, power on the VM600 system and check whether the indicator lights of the IOC4T card are normally displayed. Carry out necessary function tests according to the requirements of the manual to ensure that the card can work properly.

5. Inspection and Testing

Post-installation Inspection: After the installation is completed, carefully check whether the installation and wiring of the IOC4T card are correct, and whether there are any loose or incorrectly connected parts.

Power-on Test: After confirming that the installation and wiring are correct, power on the VM600 system and check whether the indicator lights of the IOC4T card are normally displayed. Carry out necessary function tests according to the requirements of the manual to ensure that the card can work properly.

GuiZhou YuanMiao Automation Technology Co., Ltd.

Specialized in industrial automation, we provide original imported DCS system parts, PLC system components, and comprehensive solutions for global clients. With the core values of "Leading Technology, Service Excellence," we leverage extensive industry experience and premium supply chain resources to become your reliable partner for equipment upgrades and maintenance.

Main Products:

Covering world-renowned brands:

Bently Nevada、Triconex、Woodward、Foxboro、Westinghouse、Reliance、Schneider Modicon、ABB、Allen-Bradley、Motorola、GE Fanuc、Yaskawa、ACSO、YOKOGAWA、Rexroth、NI、Bosch Rexroth、ICS Triplex、Kollmorgen、Mitsubishi、MOOG、Emerson、B&R、SST、ALSTOM、EPRO、HIMA、HONEYWELL、prosoft、AMAT 、SIEMENS、KUKA、LAM

Product categories include: DCS system parts, robot system spare parts, large-scale servo system components, widely applied in power, chemical, metallurgy, smart manufacturing, and other industries.

Service Advantages:

✅ Original imports with quality assurance

✅ Ample stock for rapid delivery

✅ Professional team for technical support

✅ Global logistics for worry-free coverage