Description

The Programmable Logic Controller was first introduced in the United States in the late 1960s, when it was called the Programmable Logic Controller (PLC), which was used to replace relays. To perform logical judgment, timing, counting and other sequential control functions. The concept of PLC was proposed by General Motors. The basic design idea of PLC is to combine the advantages of computer function perfect, flexible, universal and relay control system simple and easy to understand, easy to operate, cheap and so on, the controller hardware is standard and universal. According to the actual application object, the control content is compiled into software and written into the user program memory of the controller, so that the connection between the controller and the controlled object is convenient. PLC features and functions (1) The main characteristics of plc. The characteristics of plc are: reliable work, fast running speed, building block structure, flexible combination, good compatibility, simple programming and generation, rich, strong network function. (2) The main functions of plc. plc system can well complete the industrial real-time sequence control, condition control, counting control, step control and other functions; It can complete analog/digital (a/d), digital/analog (d/a) conversion, data processing, communication networking, real-time monitoring and other functions. Years of practice shows that plc, reliable, is designed for the factory, with reinforced components according to the requirements of the working environment, real-time scanning practice and fault diagnosis function, easy troubleshooting, won the preference of users. What makes a plc so reliable is a real-time core or operating system of executable relay logic, sequential function diagrams, function blocks, structured text, command catalogs, or a combination thereof. In case of failure, the built-in device can maintain mechanical damage and maintain an orderly and predictable sequence. 2.4 The development trend of plc: there are extremely fast logical operations and logic control, sequence control capabilities, reliability in discrete control, convenient and easy to learn programming methods, so that it has an undisputed position in the field of industrial automation based on discrete.

Application field of PLC At present, PLC has been widely used in steel, petroleum, chemical, electric power, building materials, machinery manufacturing, automobile, textile, transportation, environmental protection and cultural entertainment and other industries at home and abroad, the use is mainly divided into the following categories: 1. Switch quantity logic control Instead of the traditional relay circuit, it can realize logic control and sequence control, which can be used for the control of a single device, and can also be used for multi-machine group control and automatic pipeline. Such as injection molding machines, printing presses, stapler machines, combined machine tools, grinding machines, packaging production lines, electroplating lines, etc. 2. Industrial process control In the industrial production process, there are some continuous changes such as temperature, pressure, flow, liquid level and speed (that is, the analog amount), PLC uses the corresponding A/D and D/A conversion modules and a variety of control algorithms to deal with the analog amount, complete closed-loop control. PID regulation is a kind of regulation method used in general closed-loop control system. Process control is widely used in metallurgy, chemical industry, heat treatment, boiler control and so on. 3. Motion control PLC can be used to control circular or linear motion. Generally use special motion control modules, such as single-axis or multi-axis position control modules that can drive stepper motors or servo motors, widely used in various machinery, machine tools, robots, elevators and other occasions. 4. Data processing PLC has mathematical operations (including matrix operations, function operations, logical operations), data transmission, data conversion, sorting, table lookup, bit operation and other functions, can complete the data collection, analysis and processing. Data processing is generally used in some large control systems in the paper, metallurgy, and food industries.

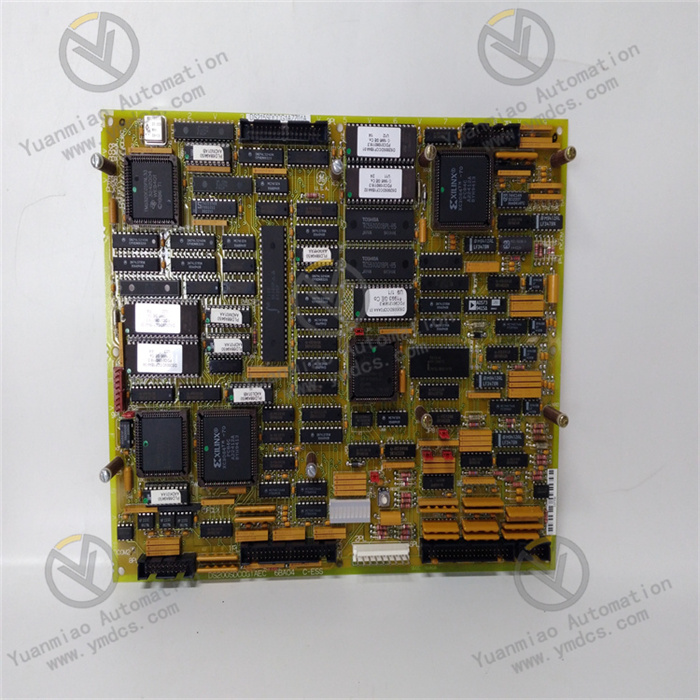

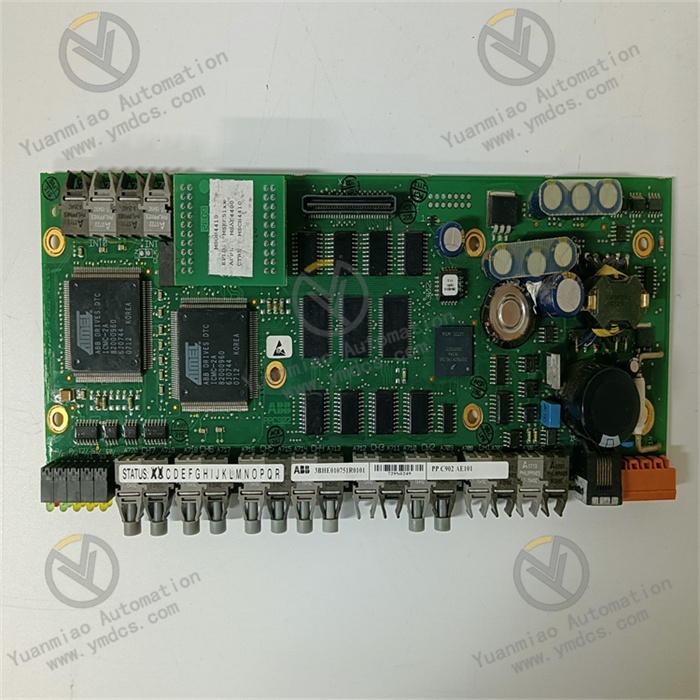

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB/