Description

Programmable controller (hereinafter referred to as PLC) from its generation to the present, the realization of wiring logic to storage logic leap; Its function from weak to strong, to achieve the progress of logic control to digital control; Its application field has grown from small to large, realizing simple control of single equipment to competent motion control, process control and distributed control and other tasks. Today's PLC in the processing of analog, digital computing, man-machine interface and network capabilities have been greatly improved, become the mainstream control equipment in the field of industrial control, in all walks of life is playing an increasing role.

Application field of PLC

At present, PLC has been widely used in steel, petroleum, chemical, electric power, building materials, machinery manufacturing, automobile, textile, transportation, environmental protection and cultural entertainment and other industries at home and abroad, the use is mainly divided into the following categories:

1. Switch quantity logic control

Instead of the traditional relay circuit, it can realize logic control and sequence control, which can be used for the control of a single device, and can also be used for multi-machine group control and automatic pipeline. Such as injection molding machines, printing presses, stapler machines, combined machine tools, grinding machines, packaging production lines, electroplating lines, etc.

2. Industrial process control

In the industrial production process, there are some continuous changes such as temperature, pressure, flow, liquid level and speed (that is, the analog amount), PLC uses the corresponding A/D and D/A conversion modules and a variety of control algorithms to deal with the analog amount, complete closed-loop control. PID regulation is a kind of regulation method used in general closed-loop control system. Process control is widely used in metallurgy, chemical industry, heat treatment, boiler control and so on.

3. Motion control

PLC can be used to control circular or linear motion. Generally use special motion control modules, such as single-axis or multi-axis position control modules that can drive stepper motors or servo motors, widely used in various machinery, machine tools, robots, elevators and other occasions.

4. Data processing

PLC has mathematical operations (including matrix operations, function operations, logical operations), data transmission, data conversion, sorting, table lookup, bit operation and other functions, can complete the data collection, analysis and processing. Data processing is generally used in some large control systems in the paper, metallurgy, and food industries.

5. Communication and networking

PLC communication includes communication between PLC and communication between PLC and other intelligent devices. With the development of factory automation network, PLC now has a communication interface, communication is very convenient.

Application characteristics of PLC

1. High reliability, strong anti-interference ability

High reliability is the key performance of electrical control equipment. Due to the use of modern large-scale integrated circuit technology, PLC adopts strict production process manufacturing, the internal circuit adopts advanced anti-interference technology, with high reliability. The use of PLC to form a control system, and the relay contactor system of the same size, electrical wiring and switch contacts have been reduced to hundreds or even thousands of one, the fault is greatly reduced. In addition, the PLC has a hardware fault self-detection function, which can issue alarm information in time when there is a failure. In the application software, the user can also program the fault self-diagnosis program of peripheral devices, so that the circuit and equipment other than PLC in the system can also obtain fault self-diagnosis protection. In this way, the whole system will be extremely reliable.

2. Complete set, perfect function, strong applicability

PLC development to today, has formed a variety of scale of serialized products, can be used in various scales of industrial control occasions. In addition to logic processing functions, PLC mostly has perfect data computing capabilities and can be used in various digital control fields. A large number of various functional units have emerged, so that PLC has penetrated into various industrial controls such as position control, temperature control, CNC. With the enhancement of PLC communication capability and the development of human-machine interface technology, it is very easy to use PLC to form various control systems.

3. Easy to learn and easy to use, welcomed by engineering and technical personnel

PLC is an industrial control equipment for industrial and mining enterprises. Its interface is easy and the programming language is easy to be accepted by engineers and technicians. The graphic symbol of ladder diagram language is quite close to the expression mode and relay circuit diagram, which opens the convenient door for people who are not familiar with electronic circuits, do not understand computer principles and assembly language to engage in industrial control.

4. The design of the system has the advantages of small workload, convenient maintenance and easy transformation

PLC replaces wiring logic with storage logic, which greatly reduces the wiring outside the control equipment, greatly shortens the cycle of control system design and construction, and makes daily maintenance easier, more importantly, it is possible to change the production process after changing the program of the same equipment. This is especially suitable

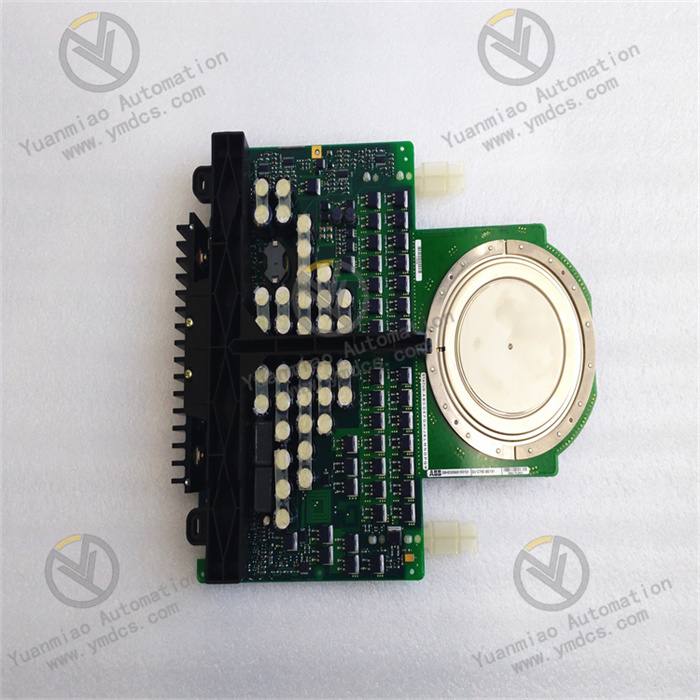

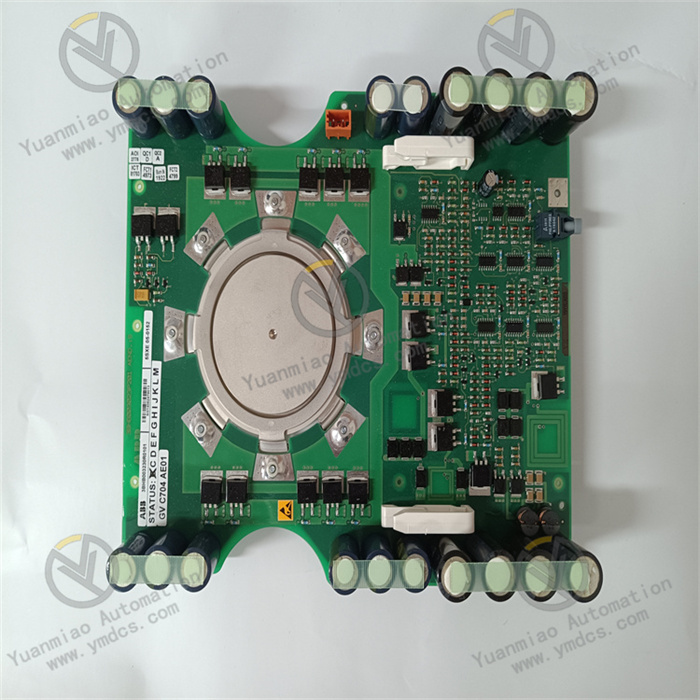

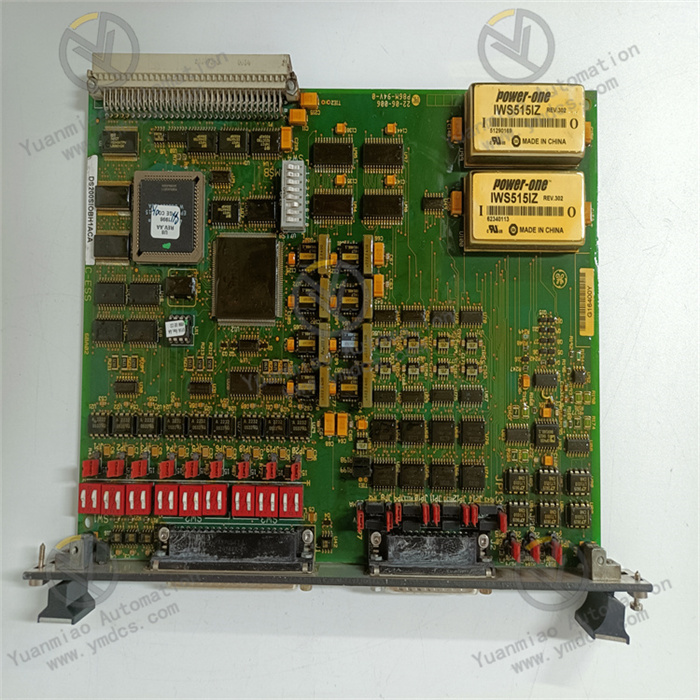

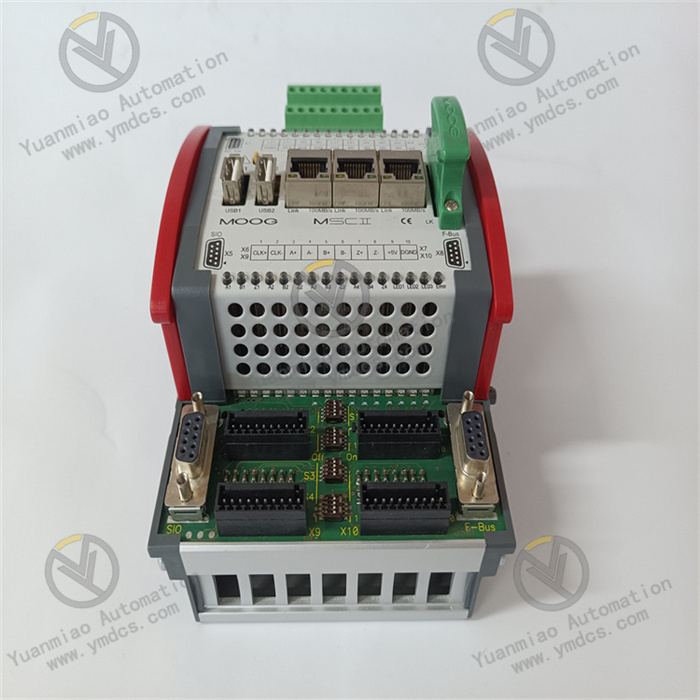

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB/