Description

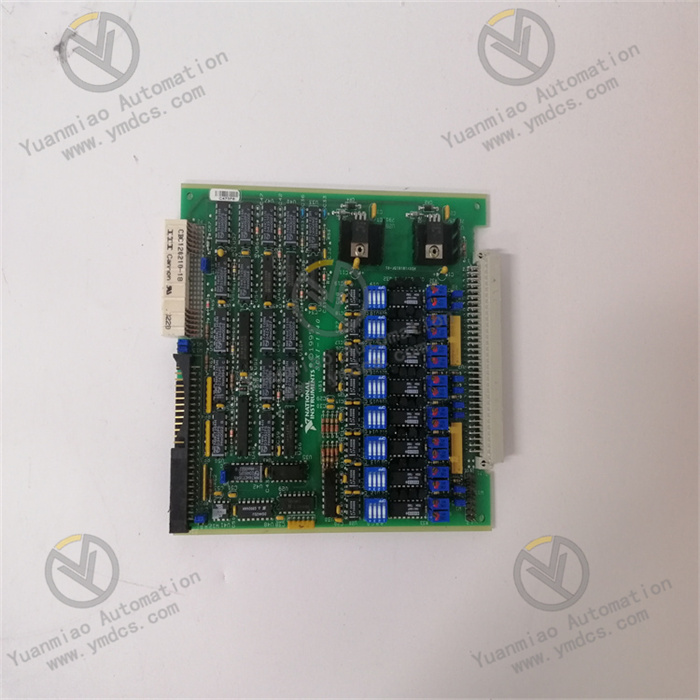

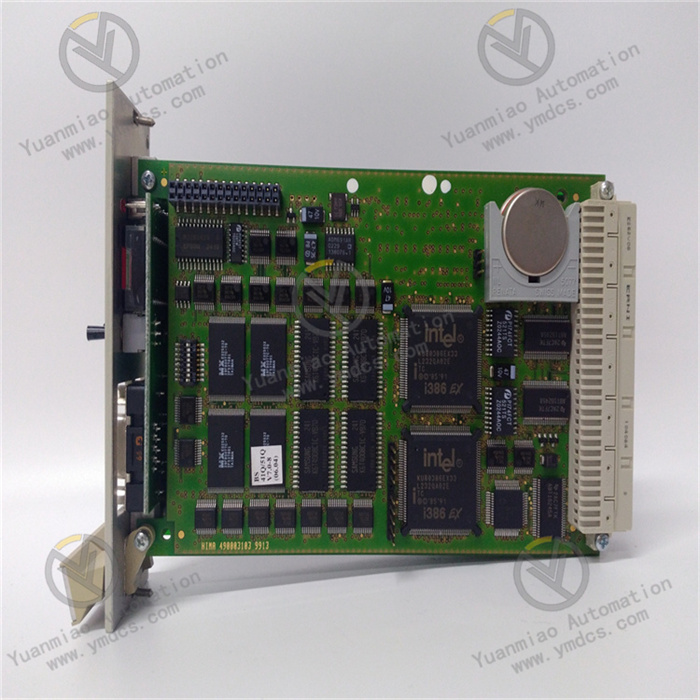

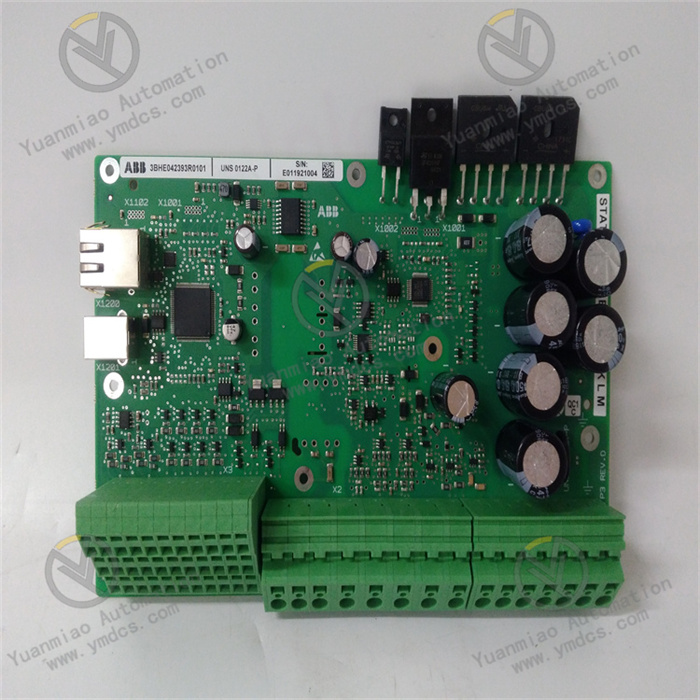

Part Number: 140471-01

Manufacturer: Bently Nevada

Series: 3500

Input Signal: -10 Vdc to +10 Vdc

Power Consumption: 10.5 watts

Product Type: Proximity Seismic Monitor I/O Module

Ethernet: 100Base-FX Fiber-Optic

Operating Temperature: -30°C to +65°C

Dimensions: 241.3 mm x 24.4 mm x 99.1 mm (H x W x D)

Weight: 0.20 kg (0.44 lb)

Country of Origin: United States

FUNCTIONAL DESCRIPTION:

140471-01 is a Proximitor Seismic Monitor I/O Module manufactured and designed by Bently Nevada as part of the 3500 Series used for monitoring seismic activity. The Proximitor Seismic Monitor I/O Module is a device designed for monitoring and managing seismic activity. The module likely serves as an interface between seismic sensors and a central monitoring or control system. Its primary function is to collect input from seismic sensors, process the data, and provide output to the monitoring system. Key features of the Proximitor Seismic Monitor I/O Module may include:

FEATURES:

- Sensor Input: The module likely accepts input from various seismic sensors, such as accelerometers or geophones, which detect ground motion caused by seismic events.

- Data Processing: It processes the raw data from the sensors, converting it into meaningful information that can be used for monitoring and analysis. This may involve filtering, amplification, and digitization of the seismic signals.

- Communication Interface: The module likely has communication capabilities to transmit data to a central monitoring system. This could be achieved through wired connections (e.g., Ethernet) or wireless protocols.

- Integration with Monitoring Systems: The device is designed to seamlessly integrate with larger seismic monitoring systems. This integration allows for real-time monitoring and analysis of seismic activity.

- Output Signals: The module may provide output signals to the monitoring system, alerting operators or triggering specific actions based on the detected seismic activity. This could include alarms, notifications, or data logging.

- Diagnostics and Maintenance Features: The module may include diagnostic tools and features to ensure the proper functioning of both the module itself and the connected seismic sensors. This helps in identifying issues and performing maintenance when necessary.

Power Supply: It likely comes with a dedicated power supply unit to ensure continuous operation, especially in critical applications where uninterrupted monitoring is essential.

Radial Vibration (Frequency Response):

- Direct Filter - User-programmable Single-pole -3dB at 4 Hz to 4000 Hz or 1 Hz to 600 Hz ± 1% accuracy: This feature allows users to program a filter with a single-pole response, meaning it attenuates the amplitude of signals outside the specified frequency range. Users can configure it to work within a range of 4 Hz to 4000 Hz or 1 Hz to 600 Hz with a remarkable accuracy of ±1%. This filtering capability is important for isolating specific frequency components in the vibration data for analysis.

- Gap Filter - -3dB at 0.09 Hz: The gap filter is designed to attenuate signals below 0.09 Hz, which is particularly useful in eliminating low-frequency noise or baseline drift from the vibration data. It helps to focus on the relevant vibration components.

- Not 1X Filter - 60 CPM to 15.8 times running speed Constant Q notch filter Minimum rejection in stopband of -34.9 dB: The "Not 1X" filter is designed to remove or notch out the fundamental frequency component (1X) associated with the running speed of the machinery. This allows for the isolation and analysis of other vibration components. It has a constant Q (Quality Factor) and provides a minimum rejection of -34.9 dB in the stopband. This is important for detecting and analyzing harmonics and other frequencies that are not the fundamental speed of the machinery.

- Smax - 0.125 to 15.8 times running speed: Smax refers to a parameter that specifies the range of vibration frequencies or speed multiples it can measure, ranging from 0.125 times to 15.8 times the running speed of the machinery. This is important for capturing vibrations at various frequencies and speed harmonics.

- 1X and 2X Vector Filter - Constant Q Filter Minimum rejection in stopband of -57.7 dB: The 1X and 2X vector filters are designed to isolate and analyze vibrations that are exactly at the running speed (1X) and its second harmonic (2X). These filters employ a constant Q filter design and provide a minimum rejection of -57.7 dB in the stopband. This high rejection is essential for accurately identifying and assessing these specific components.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/BentlyNevada/