Description

The 1900/55 General Purpose Equipment Monitor is designed to continuously monitor and protect equipment that is used in a variety of applications and industries. The monitor’s low cost makes it an ideal solution for general-purpose machines and processes that can benefit from continuous monitoring and protection. Inputs The 1900/55 provides four transducer inputs and four temperature inputs. Software can configure each transducer input to support 2- and 3-wire accelerometers, velocity sensors or proximity sensors. Each temperature input supports Type E, J, K, and T thermocouples, and 2- or 3-wire RTDs. Outputs The 1900/65A provides six relay outputs, four 4-20 mA recorder outputs, and a dedicated buffered output. The user can use the 1900 Configuration software to configure the relay contacts to open or close according to the OK, Alert and Danger statuses of any channel or combination of channels, and to provide data from any variable from any channel on any recorder output. The dedicated buffer output can provide the signal for each transducer input. A Modbus Gateway option allows the monitor to provide static variables, statuses, event list, time and date information directly to any Modbus client, including Distributed Control Systems (DCSs), Supervisory Control and Data Acquisition (SCADA) systems, Programmable Logic Controllers (PLCs), or System 1 software. The monitor uses an internal counter and a Modbus client/master time reference to generate time and date information. Users can upgrade monitors without the Modbus Gateway by ordering the 1900/01 Communications Upgrade (see the Ordering Information section). The 1900/55 supports Modbus communications via Ethernet and a software-configurable RS232/485 serial port.

BENTLY3300XLNSv eddy current sensor system

BENTLV330OXLNSv, an eddy current sensor system in the United States, has a 5mm end diameter and a shorter linear range of 60mis (1.5mm), which is applicable to small area of the measured target surface, reduced side view or counterbore clearance, and other restrictions on the use of our standard 5mm/8mm eddy current sensor.

BENTLY330016mm high temperature eddy current sensor system

The BENTLV330016mm eddy current sensor system of the United States is used in a high temperature environment of 350 ° C (662 “F), such as some gas and steam turbine applications where the temperature exceeds what our standard eddy current probes and cables can withstand. The probe end diameter of the high temperature sensor system is 16mm, providing a linear range of 160mils (4mm).

BENTLY330OREBAM sensor system

BENTLV330OREBAM, a high gain eddy current sensor system, is used to measure the micro inch deformation of outer ring of rolling bearing. Compared with the seismic sensor installed on the shell, such as accelerometer, it provides more direct bearing state measurement, and has higher sensitivity and signal to noise ratio. The system has two linear ranges: 16mils (400um) and 40V/mm output, or 8mils (200um) and 20V/mm output.

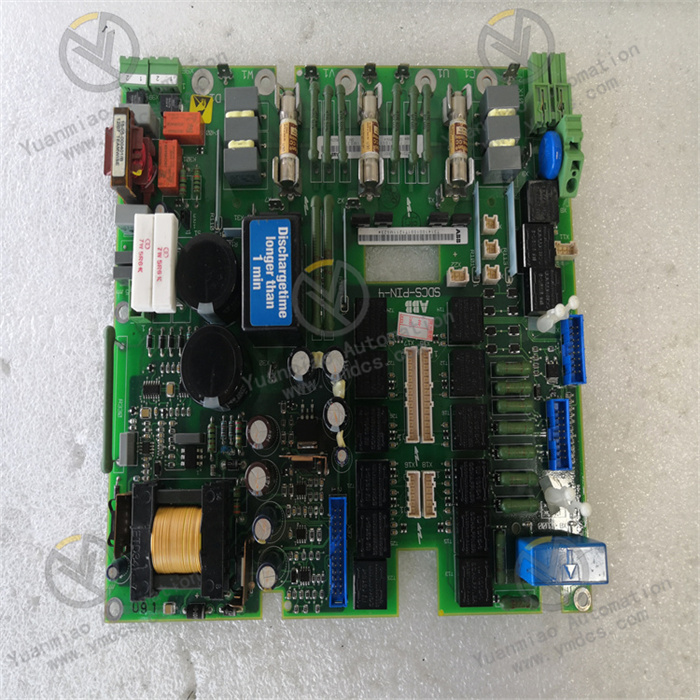

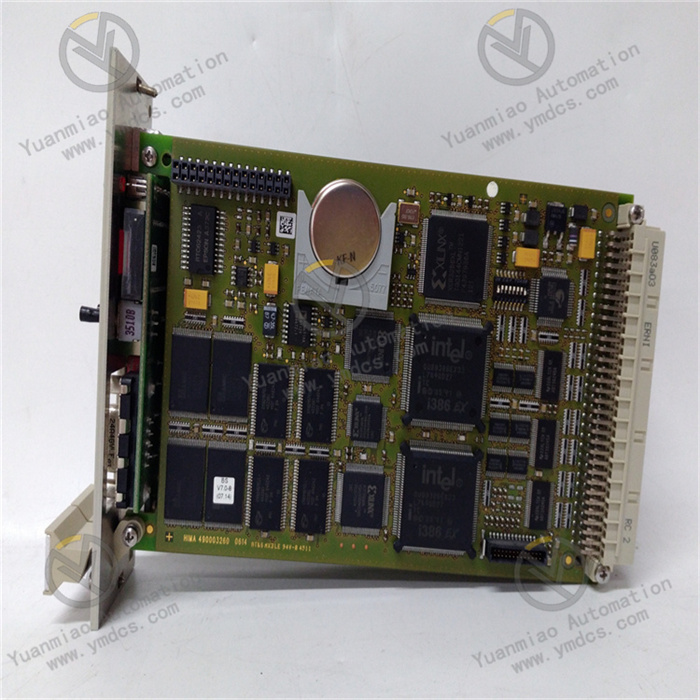

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/BentlyNevada/