Description

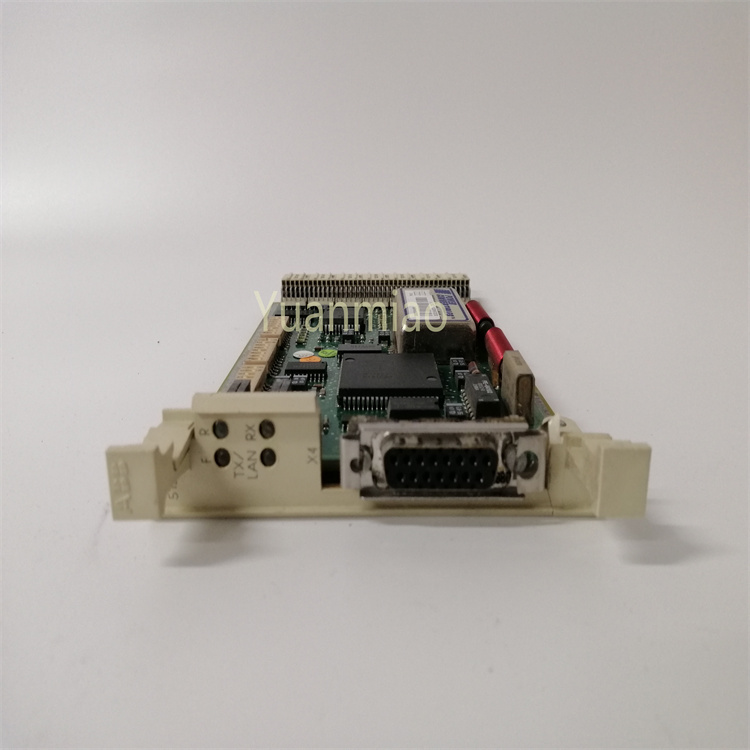

3BHE022291R0101 belongs to ABB's PCD230A101 static excitation system. Here are some possible action points: Initial setup - Parameter configuration: Set key parameters such as voltage regulation range, current limit, and excitation gain through the system operating interface or programming software according to the rated parameters, operating requirements, and network characteristics of the synchronous generator. - Communication Settings: If you need to communicate with other devices or control systems, you should configure the parameters of the communication interface, such as baud rate, data bit, stop bit, communication protocol, etc., to ensure normal communication with the host computer or other related devices.

Running operation

- Start operation: After confirming that the system is connected correctly, the parameters are set correctly and the external conditions are met, the excitation system can be started by the start button on the operation panel or the remote control command, so that the system starts to provide excitation current for the synchronous generator, establish a stable magnetic field, and then make the generator output stable voltage and frequency.

- Operation monitoring: Pay close attention to the operating status of the system, including the display value of the generator terminal voltage, excitation current, excitation voltage and other key parameters, to ensure that they are within the normal range. At the same time, observe whether the system has alarm information or abnormal instructions, and deal with any problems in time.

- Regulation operation: When the generator load changes or the power grid voltage fluctuates, it may be necessary to manually or automatically adjust the output of the excitation system according to the actual situation to maintain the stability of the generator voltage. It can be achieved by adjusting the adjustment knob on the panel or entering the corresponding adjustment instruction on the operation interface.

Maintenance and troubleshooting

- Regular maintenance: Periodically check whether the hardware connection of the system is loose, whether there is dust accumulation, and whether the heat dissipation is good. Clean the surface of the equipment and ensure that the vents are clear. Upgrade the system software and back up parameters at specified intervals to prevent data loss.

- Troubleshooting: When a system fault occurs, first check the fault alarm information and determine the general scope and type of the fault according to the prompt. For example, if there is an overcurrent alarm, it may be necessary to check whether the load is overloaded and whether the current detection circuit is normal. For some simple faults, follow the troubleshooting guide in the operation manual to handle them. For complex faults, professional technicians should be contacted in time for maintenance.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB