Description

The following is the usage guide for the ABB PKZM0-16-T motor protection switch: Preparation before Installation Check the Appearance: Check whether the protection switch has any damage or deformation, and whether there are defects such as scratches and cracks on the surface. Ensure that all markings are clear and distinguishable, that all wiring terminals are not loose or damaged, and that the casing is not cracked. Confirm the Parameters: According to the specifications of the motor to be protected and the actual application scenario, confirm that the parameters of the PKZM0-16-T, such as rated current, rated voltage, and tripping characteristics, are compatible with the requirements of the motor and the circuit. For example, if the rated current of the motor is 10A, the rated current of the selected PKZM0-16-T should cover and be suitable for this value. Prepare the Tools: Prepare the tools required for installation, such as screwdrivers and wire strippers. If it involves busbar connections and other operations, tools such as wrenches may also be needed. Installation Process Select the Location: It should be installed in a place that is dry, well-ventilated, free from vibration, and free from strong electromagnetic interference, and it should be easy to operate and maintain. Usually, it is installed in the motor control cabinet, as close as possible to the power inlet of the motor. Electrical Connection: According to the specifications of the motor and the power supply, correctly connect the power cord to the inlet terminal of the protection switch, and connect the motor wire to the outlet terminal. When wiring, ensure that the wires are firmly connected and tighten the screws to avoid loose connections that may cause heating and poor contact. Pay attention to distinguishing the live wire, neutral wire, and ground wire, and follow the general principle of "neutral wire on the left, live wire on the right, and ground wire on the top". For three-phase motors, the three-phase wires should be correctly connected. Fixed Installation: Use screws or clips to firmly install the protection switch on the control cabinet or the installation plate to ensure that it will not loosen or shift during operation.

Debugging and Usage

Parameter Setting: According to parameters such as the rated current of the motor, set parameters such as the overload protection current value, short-circuit protection current value, and delay time through the adjustment knob or DIP switch on the protection switch. Generally, the overload protection current can be set to 1.1-1.3 times the rated current of the motor.

Check the Connections: After the installation and parameter setting are completed, check again whether all the wiring is correct and firm, and whether the grounding is reliable.

Power-on Test: Before connecting to the power supply, ensure that the motor and related equipment are in the stopped state. After connecting to the power supply, observe whether there are abnormal phenomena such as overheating, arcing, and smoking of the protection switch, and at the same time, check whether the motor can start and operate normally. If there are any problems, cut off the power supply immediately for troubleshooting.

Function Test: The sensitivity and accuracy of the action of the protection switch can be tested by simulating fault conditions such as overload and short circuit. For example, an adjustable load can be used to gradually increase the motor current, and observe whether the protection switch acts after the set overload current value and delay time.

Maintenance and Upkeep

Regular Cleaning: Regularly clean the dust and dirt on the surface of the protection switch to prevent the accumulation of dust from affecting the heat dissipation and insulation performance. When cleaning, cut off the power supply first and wipe it with a dry and soft cloth.

Check the Connection Parts: Regularly check whether the wiring terminals are loose or oxidized. If they are loose, tighten them in a timely manner. If there is oxidation, clean or replace the terminals.

Function Check: Regularly conduct function tests to check whether the protection functions of the protection switch, such as overload and short circuit protection, are normal, and ensure that it can act reliably when needed.

Environmental Check: Ensure that the working environment temperature and humidity of the protection switch are within the allowable range, and there are no corrosive gases, liquids, and strong electromagnetic interference sources around.

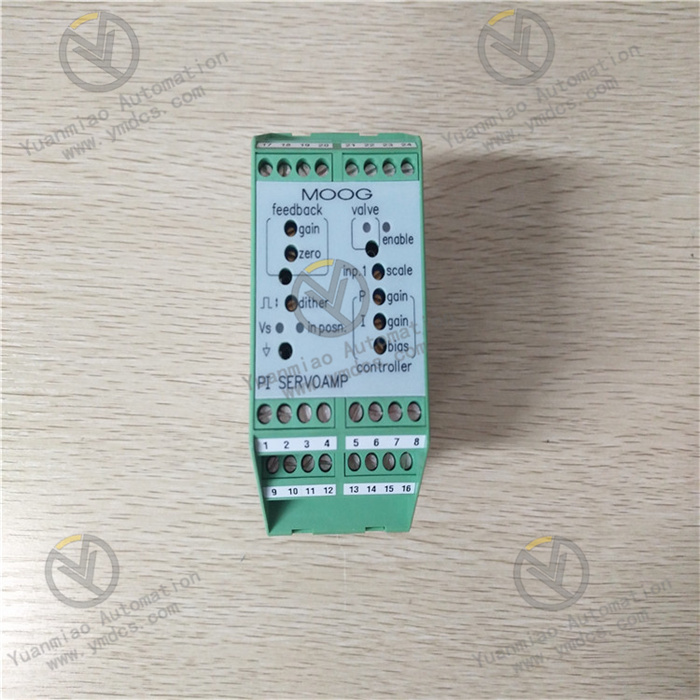

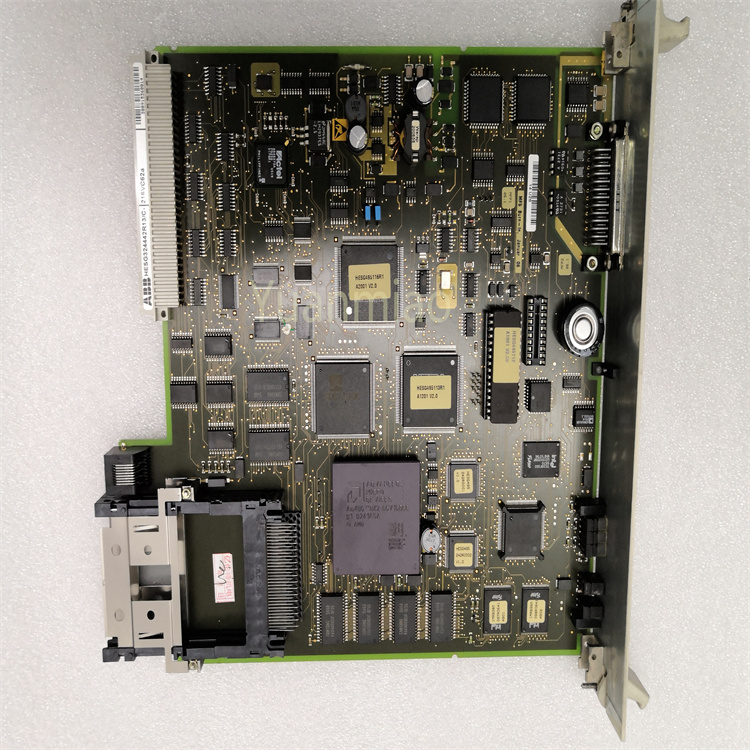

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB