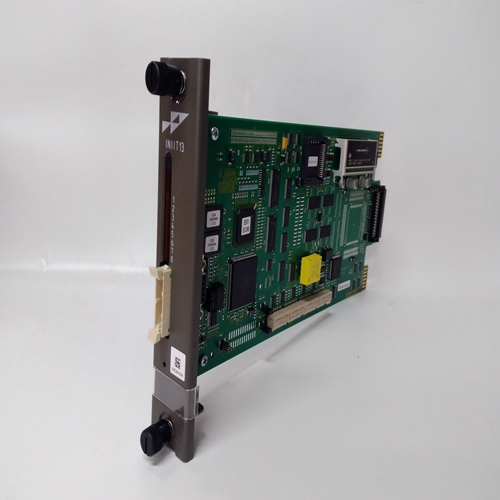

Description

The 8552-674 controller may have the following common working principles: Signal Acquisition: The controller will be connected to various sensors, which can monitor various parameters of the system, such as pressure, temperature, rotational speed, flow rate, etc. For example, in an engine control system, there may be a temperature sensor to detect the engine's coolant temperature or exhaust temperature, and a pressure sensor to measure the intake air pressure, etc. The controller receives the electrical signals transmitted by these sensors through a specific interface circuit. These signals may be analog signals (such as voltage or current signals) or digital signals. Signal Processing: The received signals may first go through pre-processing steps such as filtering and amplification to remove noise and interference and adjust the signals to a range suitable for internal processing. Then, the microprocessor or digital signal processor (DSP) inside the controller will analyze and calculate the signals. It will compare the collected actual parameter values with the pre-set target values or reference values to calculate the deviation.

Control Algorithm Operation:

Based on the calculated deviation, the controller will use specific control algorithms (such as the Proportional-Integral-Derivative control algorithm, that is, the PID control algorithm) to calculate the appropriate control output. The purpose of these algorithms is to make the actual parameters of the system as close as possible to the target values by adjusting the control quantity. For example, if it is detected that the engine speed is lower than the set value, the controller will calculate the required increase in fuel supply or other control quantities according to the deviation and the control algorithm.

Output Control:

According to the calculation results of the control algorithm, the controller will output corresponding control signals. These signals can be analog signals, which are used to control the opening degree or state of some actuators (such as regulating valves, solenoid valves, etc.); they can also be digital signals, which are used to drive switching devices such as relays and contactors. For example, the controller may send a current signal to control the opening time and fuel injection amount of the fuel injection valve, thereby adjusting the output power of the engine.

Feedback Regulation:

After performing the control operation, the actual parameters of the system will change. The sensors will collect these parameters again and feed back the new signals to the controller. The controller will compare, calculate and adjust again according to the new feedback signals, forming a closed-loop control process to continuously optimize the performance and stability of the system.

The technical parameters of the Woodward 8552 - 674 controller are as follows:

Control method: Voltage vector.

Output voltage regulation method: PAM control.

Rated voltage: 380V.

Feature service: 100kHz.

In addition, although not specific to this model of controller, the relevant characteristics of the Woodward MicroNet TMR control system can also be used as a reference:

It adopts a highly reliable triple - modular redundant fault - tolerant technology of CPU with a two - out - of - three voting mechanism, ensuring that a single - point fault does not affect the normal operation and shutdown of the unit.

It uses a dual - redundant and flexibly configurable power supply to improve system reliability.

The I/O modules have flexible configurations and can form single - point, dual - redundant, or triple - redundant I/O forms or combinations.

It uses synchronous I/O with a definite scanning rate.

The processing cycle of key control loops can reach 5ms.

The time - stamp resolution is 1ms for switching events and 5ms for analog events.

It uses the IEC61131 - 3 programming language.

It can interface with major DCS systems and supports multiple communication protocols.

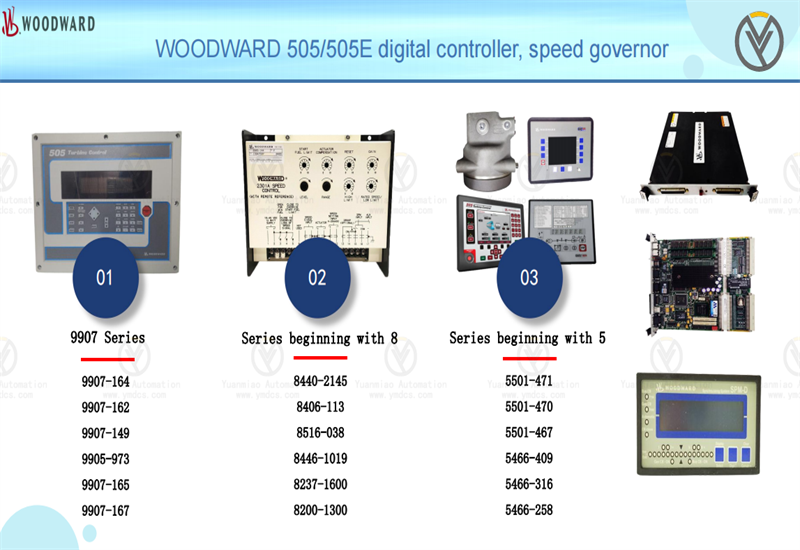

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Woodward/