Description

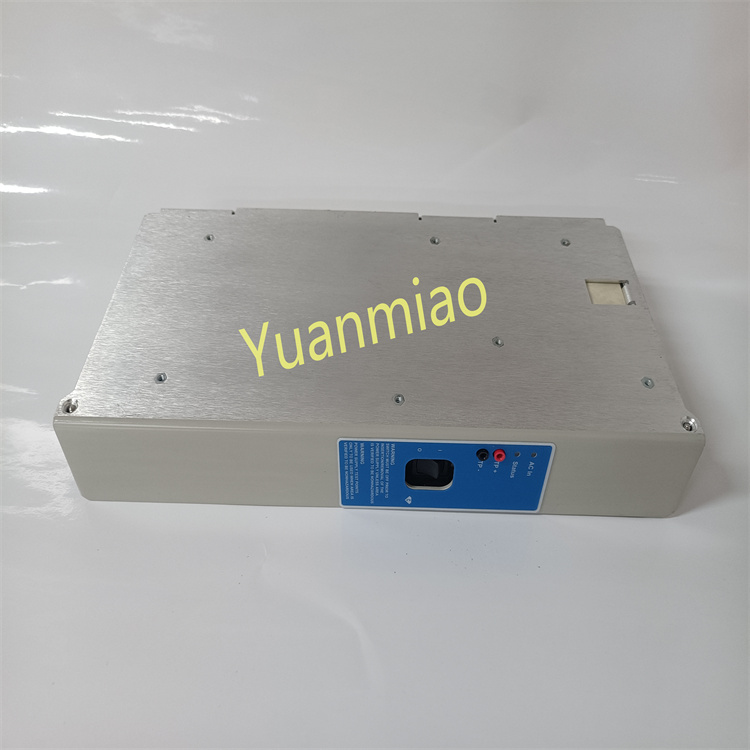

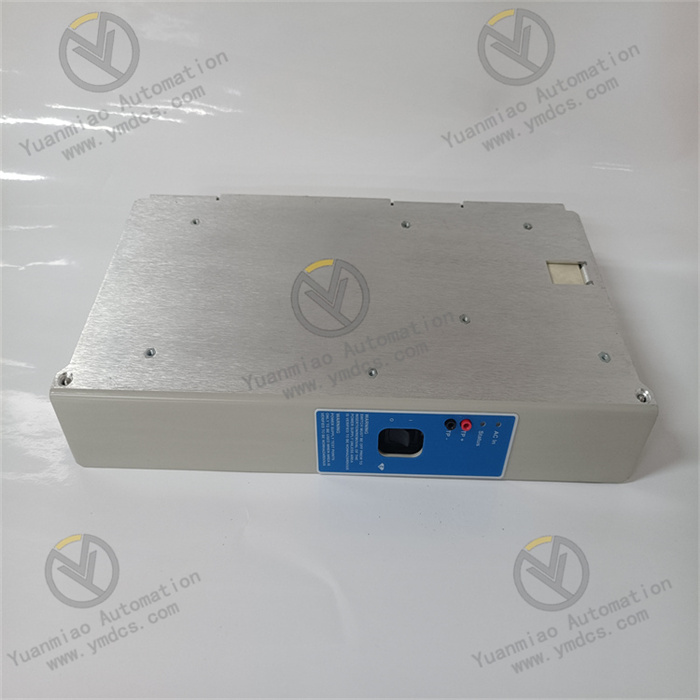

Honeywell SC-UCMX01 51307195-175 is a high-performance industrial control module. Functional characteristics Powerful communication function: support a variety of communication protocols, such as Modbus, Profibus, etc., can achieve high-speed and stable data transmission. At the same time, it provides RS-485, RS-232, CAN and other interface types, which can meet the connection needs of different devices, and can be integrated with other Honeywell or third-party devices, with strong scalability, and can build a more complete automation solution. High reliability: with anti-lightning, anti-electromagnetic interference and other functions, can operate stably in harsh industrial environments. And support remote monitoring and maintenance functions, easy troubleshooting and software upgrade, easy maintenance. Electrical characteristics: The working voltage is 220V, the output frequency is 30kHz. These electrical parameters make it suitable for a variety of industrial scenarios, providing stable power support and accurate frequency control for the equipment. Application: Suitable for automation systems, manufacturing plants and other industrial environments with high requirements for precise frequency control, it has a wide range of applications in petrochemical, energy, power and other industries. For example, in petrochemical production, it can be used to accurately control the operating frequency of various types of pumps, compressors and other equipment to ensure the stability and efficiency of the production process. Physical characteristics: Usually compact design, small size, can adapt to space limited installation environment, can be easily installed in the control cabinet or other equipment, easy to integrate into the existing system, will not take up too much space. Product advantages: After rigorous testing and quality assurance process, in line with relevant industry standards, is a certified product. Its advanced design, accurate control capabilities and high reliability can provide stable and efficient control support for industrial automation systems, helping enterprises to improve production efficiency and reduce maintenance costs.

General installation procedures of Honeywell SC-UCMX01 51307195-175. Please ensure that the relevant power supply is cut off before installation, and strictly follow the product manual and safety specifications:

1. Prepare

Confirm the installation environment: choose a dry, clean, well-ventilated and no violent vibration and strong electromagnetic interference environment, the ambient temperature should be within the product's specified operating temperature range (generally -20 ° C to + 60 ° C), humidity does not exceed the specified value (such as 5%-95% no condensation).

Prepare installation tools: Prepare proper tools, such as screwdrivers and wrenches, and necessary installation accessories, such as guide rails and screws.

Check product integrity: Open the package and check whether the appearance of SC-UCMX01 module is damaged and whether the accessories are complete, including the module body, instructions, and wiring terminals.

2. Install the module

Select mounting method: The module generally supports two mounting methods, namely DIN rail mounting and panel mounting.

DIN rail mounting: Fix the DIN rail to the control cabinet or mounting plate to ensure that the rail is firmly installed. Align the buckle of the module with the DIN rail and gently press the module down until the module is firmly stuck to the rail.

Panel installation: Cut holes on the panel according to the dimensions of the module installation holes. Place the module on the mounting hole and secure the module to the panel using mounting screws to ensure that the module is installed smoothly and securely.

3. Electrical connection

Power connection: According to the power requirements of the module (usually 24V DC or other specific voltage), connect the power cord to the power terminal of the module. Make sure the power supply is properly polar and securely connected. Generally, the red line is connected to the positive electrode, and the black line is connected to the negative electrode.

Communication connection:

Serial port communication connection: If RS-485 or RS-232 serial ports are used for communication, connect the corresponding communication cable to the serial port terminal of the module. For RS-485 communication, pay attention to the connection sequence of A and B lines; For RS-232 communication, the connection is made according to the specified pin definition.

Ethernet communication connection: If the module supports Ethernet communication, use a network cable to connect the Ethernet interface of the module to the network switch or other network devices. Ensure that network cables are securely connected and port indicators are on.

I/O connection: Connect input and output signal cables to the corresponding I/O terminals of the module based on actual application requirements. Before connecting, confirm the type (such as analog, digital) and specifications of the signal cable to ensure that the connection is correct. For example, for analog input and output, use appropriate shielded cables and do a good job of grounding.

4. Configure modules

Setting communication parameters: Through the configuration interface of the module (such as serial port or Ethernet interface), the corresponding configuration software (such as the special configuration tool provided by Honeywell) is used to set the communication parameters of the module, such as baud rate, data bit, stop bit, and parity check. Ensure that these parameters are consistent with the communication parameters of other connected devices (such as PLC, host computer).

Set functional parameters: According to the specific application requirements, set the functional parameters of the module, such as input and output range, alarm threshold, communication protocol, etc. For example, if used for analog output control, set the output range to 4-20mA or 0-10V, etc.

5. Check and test

Appearance check: Check whether all cables are securely connected, loose or damaged. Whether the module is securely installed and screws are tightened.

Power test: Power on the module and check whether the power indicator on the module is on to ensure that the module is powered on. Check whether the communication indicator on the module blinks normally, indicating that the communication function is normal.

Function test: By configuring software or connected devices, send test commands to check whether the input and output functions of the module are normal. For example, send an analog output value to check whether the connected device can receive the correct signal; Read the input signal to confirm whether the module can accurately collect data.

6. Document records

Record the installation position, cable direction, and configuration parameters of the module for future maintenance and troubleshooting.

The above installation procedure is only a general guide. The specific installation operation may vary according to the actual situation and the requirements of the product manual. If you have any questions

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Honeywell/