Description

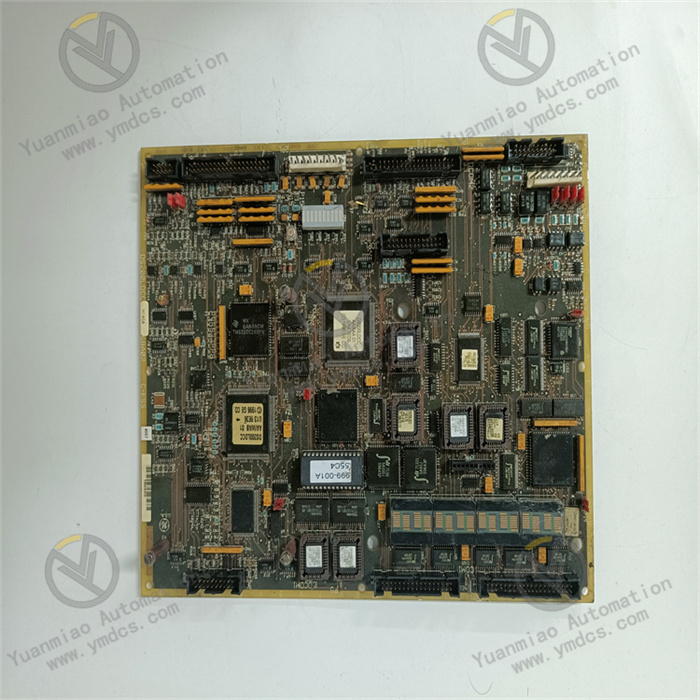

The Honeywell 51402455-100 MP-DNCF02-200 is a Honeywell dual-node card for industrial automation. Dimensions: 19 inches x 24 inches x 3.5 inches, weighing 15 pounds (about 6.8 kg), a single card weighs 0.76 kg, compact design, suitable for installation in a standard industrial control cabinet. Electrical characteristics: Support 120/230V AC, 50/60Hz power input, with a wide voltage input range, can adapt to different industrial power environment. As a single-phase power controller, the input voltage is 100-240V AC, the output voltage is 0-100V DC, and the rated current is 2A, which can provide a stable DC output to power industrial equipment. Features: The card has the function of two nodes, each node can independently perform a specific function, and occupy a specific address on the local control network (LCN), can realize redundant control or share different control tasks, improve the reliability and flexibility of the system. The card is integrated with a fan assembly, which can effectively dissipate heat, ensure a stable working temperature during long-term operation, reduce the risk of failure caused by overheating, and improve the stability and service life of the device. Application: Mainly used in the field of industrial automation, such as manufacturing, petrochemical, electric power and other industries, can be used in distributed control system (DCS), to achieve a variety of industrial equipment monitoring, control and data acquisition functions, to help enterprises improve production efficiency, reduce costs, ensure production safety.

Installation guide for Honeywell 51402455-100 MP-DNCF02-200:

1. Prepare for installation

Checking devices and accessories: Check whether devices are in good condition and accessories are complete, including control cards, mounting brackets, screws, power cables, and communication cables.

Understand the installation environment: Ensure that the installation position meets the requirements of the device, such as temperature, humidity, dust, and shock. The control card is generally suitable for industrial environments, and the operating temperature is usually -20 ℃ to + 60℃.

Tools: Obtain common tools, such as screwdrivers and wrenches.

2. Select an installation position

Space requirements: Select a position with sufficient space to facilitate the installation and subsequent maintenance of the controller card. Reserve a certain space for heat dissipation and cable connection.

Electrical safety: The installation position should be far away from strong electromagnetic interference sources, such as large motors, transformers, etc., to avoid electromagnetic interference affecting the normal operation of the control card. In addition, ensure that the installation position is well grounded to ensure the safety of equipment and personnel.

3. Install the control card

Fix the mounting support: If there is a supporting mounting support, fix the support to the selected position first, and use screws or other fixing devices to ensure that the support is secure and reliable.

Install the control card to the support: Place the control card on the support smoothly and fix it to the support by screws or clasps to ensure that the control card is firmly installed and does not shake or loosen.

4. Connect cables

Power cable connection: Connect proper power cables according to the power requirements of the control card. The controller card supports 120/230V AC and 50/60Hz power input. Connect one end of the power cable to the power port on the controller card and the other end to a power socket or power distribution unit. Cables should be firmly connected to avoid loose connections that may cause poor contact or electrical faults.

Communication cable connection: If you need to communicate with other devices, connect corresponding communication cables based on the communication protocol and interface type. For example, if Modbus TCP/IP is supported, you can use a network cable to connect the network ports of the controller card to those of other devices. Ensure that the communication cables are correctly connected, and secure and protect the cables to prevent them from being pulled or damaged.

Input and output line connection: According to the actual application requirements, connect the input and output cables of the control card, and connect them with related sensors, actuators and other devices to realize the monitoring and control functions of industrial equipment. When wiring, carefully check the wiring diagram of the control card and the equipment manual to ensure the accuracy of the wiring.

5. Check and test

Cable check: Before powering on the power, check whether all cables are firmly connected and correct, and whether they are loose, short circuiting, or open.

Power check: Confirm whether the power supply voltage meets the requirements of the control card, check whether the power line is normal, and there are no safety risks such as leakage and overload.

Function test: After the power is turned on, observe whether the indicator light of the control card is normally on, and check whether it performs self-test and enters the normal working state. If the control card supports relevant diagnostic functions or software, functional tests can be carried out through the corresponding tools to check whether the functions of the control card are normal, such as the acquisition and control of input and output signals, and whether the communication functions are working normally.

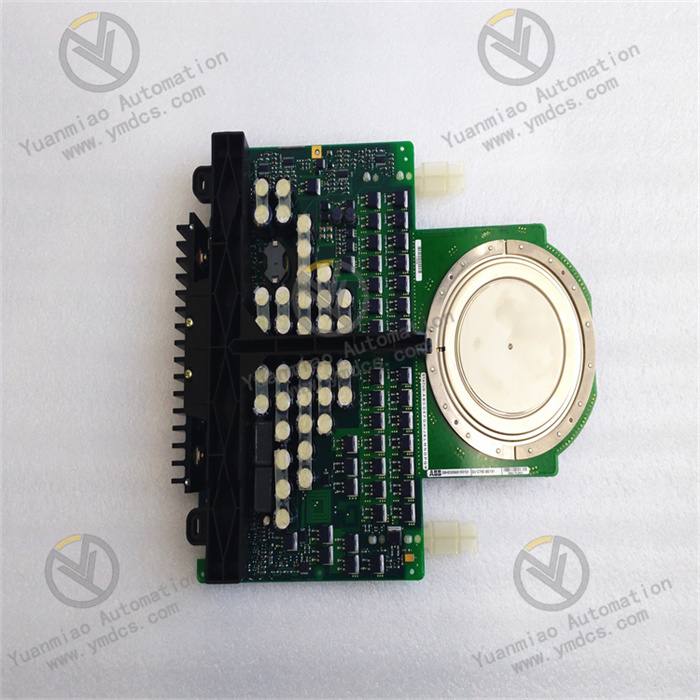

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Honeywell/