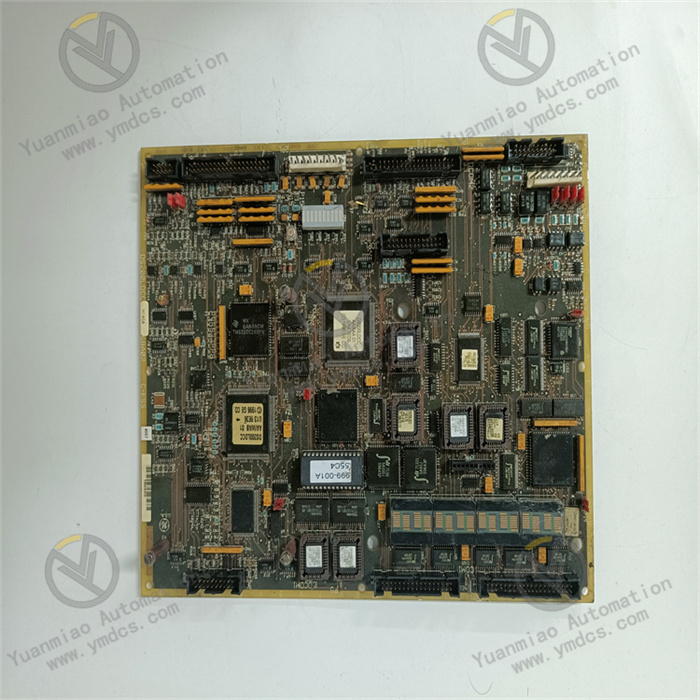

Description

The Honeywell SC-TCMX01 is an industrial control module with product number 51307198-175. Functional characteristics: It is mainly used for accurate adjustment and monitoring of temperature and pressure parameters in industrial environment. With high-precision monitoring and adjustment capabilities, it can ensure that the temperature and pressure parameters in the industrial process are kept within the set range, which helps to improve product quality and production efficiency, and reduce production accidents and quality problems caused by parameter fluctuations. Performance parameters: The working voltage is 220V, the output frequency is 30kHz. With CE, ROHS and other certifications, in line with international quality and environmental standards to ensure product safety and reliability. Physical Features: The compact design allows easy installation and integration into existing industrial control systems, saves installation space, and is easy to maintain. The shell is made of high-quality materials, with good wear resistance, corrosion resistance and anti-interference, and can work stably in harsh industrial environments for a long time, such as high temperature, humidity, dust and strong electromagnetic interference places. Application: Widely used in manufacturing, petrochemical, electric power, metallurgy and other industries. For example, in the manufacturing industry, it can be used to control the temperature and pressure of production equipment to ensure the stability of the production process; In the petrochemical industry, it can be used to monitor and control the temperature and pressure parameters of reactors, pipelines and other equipment to ensure production safety and product quality.

Installation procedure

Select installation location: Select a smooth, dry, vibration-free location that is easy to wire and operate, such as in an industrial control cabinet. Keep away from heat sources, strong electromagnetic interference sources, and damp places.

Secure the module: Secure the SC-TCMX01 module firmly in the selected position using appropriate installation tools (such as screws, etc.) to ensure that the module does not loosen due to vibration or other external forces.

Connect the power supply: Correctly connect the 220V AC power supply to the power input end of the module according to the label on the module. Ensure that the cable connection is secure to prevent loosening or short circuit.

Connect the signal line: According to the actual application requirements, the signal output line of the temperature, pressure and other sensors is connected to the corresponding input channel of the module, and the control signal output line of the module is connected to the corresponding execution equipment (such as valves, motors, etc.). Pay attention to the polarity and correctness of cable connections to avoid device damage or system faults caused by incorrect cable connections.

Configuration and operation

Initial setup: After the module is powered on, the initial setup is carried out through the control system or human-machine interface (if any) connected to it. This may include setting operating modes, input and output signal types, range ranges, control parameters, etc. The setting method and parameters vary according to actual application scenarios and user requirements.

Temperature and pressure parameter Settings: Set the desired temperature and pressure Settings in the control system according to the requirements of the industrial process. Specific values can be manually entered, or dynamically adjusted according to changes in the production process.

Control function configuration: According to the actual control requirements, configure the control function of the module, such as PID control parameter adjustment, alarm threshold setting, etc. The PID parameter setting needs to be optimized according to the specific controlled object and control requirements to achieve stable and accurate control effect. The alarm threshold should be set to ensure that the temperature or pressure outside the normal range can be detected in time so that appropriate measures can be taken.

Real-time monitoring and adjustment: During the operation of the system, the actual value of temperature and pressure is monitored in real time through the control system or human-machine interface, and compared with the set value. If the actual value is found to deviate from the set value, the module automatically adjusts the output signal according to the control algorithm to encourage the temperature and pressure to return to the set value. At the same time, the operator can also manually adjust the control parameters or set values according to the actual situation to meet different production needs.

Care and maintenance

Periodic inspection: Periodically check the appearance of the module for damage, signs of overheating, and loose wiring. Check whether dust accumulates in the vents. If necessary, clean the dust in time to ensure proper heat dissipation.

Clean the module: Use a clean, dry cloth to gently wipe the dust and dirt on the surface of the module. Avoid using cleaners containing corrosive substances to avoid damage to the module housing and internal circuitry.

Performance test: Perform regular performance tests on the module to check the accuracy and stability of its temperature and pressure monitoring and control. By simulating the actual working conditions, different temperature and pressure signals can be input to observe whether the output response of the module meets the expectations. If the performance is abnormal, rectify the fault in time.

Replace wearing parts: Periodically replace parts that may wear out or age, such as fuses and relays, according to the usage of the module and the manufacturer's recommendations. When replacing parts, make sure to use genuine spare parts that are compatible with the module and follow the correct replacement method.

troubleshooting

Power failure: If the module fails to start or works abnormally, check whether the power supply is normal. Check that the power plug is plugged in, that the power switch is on, and that the fuse is blown. If the fuse is found blown, replace the fuse with the same specification and power on again. If the problem still exists, it may be that the power circuit inside the module is faulty, and you need to contact professional maintenance personnel for overhaul.

Abnormal temperature or pressure monitoring: If the temperature or pressure monitoring value is inconsistent with the actual value, check whether the sensor works properly. You can check whether cables to the sensor are loose or whether the sensor is damaged. If the sensor is working properly

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

【 Disclaimer 】 We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder. This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link:http://www.ymdcs.com/Honeywell/