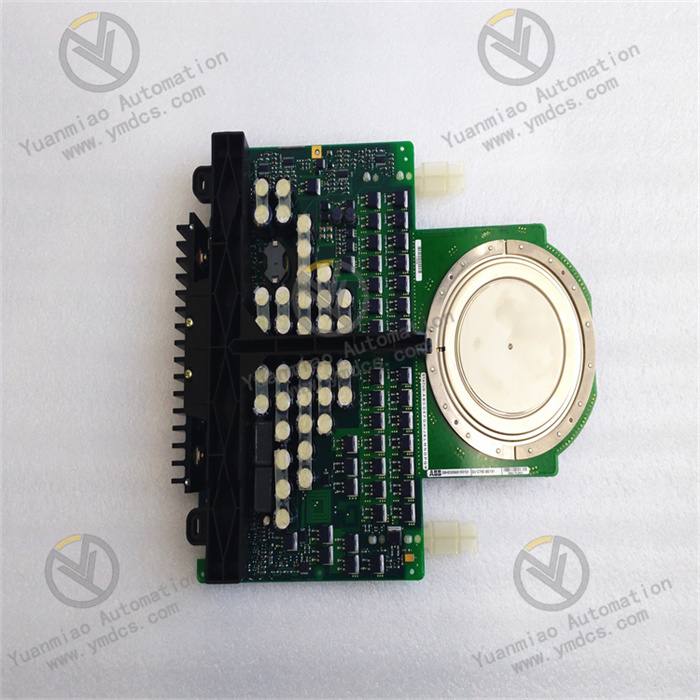

Description

ABB IDPG 940128102 is a digital volume control board for industrial automation. Functional characteristics Digital signal processing: can receive digital input signals from various sensors, these signals can indicate the status of the device, position, speed and other key parameters, and analyze the signal, so that the system can make corresponding responses or control decisions. Digital output control: digital output signals can be generated to control actuators, valves, motors and other equipment. The output signal can be adjusted according to the preset logic or algorithm to achieve precise control of industrial equipment. Communication capability: Usually equipped with a variety of communication interfaces, such as Ethernet, Profibus, Profinet, etc., to support communication with other industrial control systems or equipment, easy to integrate into the existing automation network, to achieve data exchange and sharing. Flexibility and scalability: Support a variety of configuration and programming methods, users can adjust the parameters and functions of the board according to actual application scenarios to meet specific control requirements. The input and output interfaces and communication protocols can also be customized and expanded according to actual needs to adapt to industrial automation systems of different sizes and complexities.

Performance advantage

High precision and high reliability: The use of high-performance processors and large-capacity memory, with high-precision digital signal processing capabilities, to ensure the accuracy and stability of signal processing, to ensure accurate operation in various industrial environments.

Strong anti-interference ability: with excellent anti-electromagnetic interference performance, the use of high-quality materials and manufacturing processes, can work stably in harsh industrial environments, reducing failure and maintenance costs.

Easy to install and configure: Standardized interfaces and communication protocols enable seamless connection and integration with other industrial automation equipment. At the same time, it supports a variety of programming languages and development environments, which is convenient for users to customize and develop.

Application field

Industrial automation: used to connect and control a variety of digital output equipment, to achieve the monitoring and control of industrial processes, widely used in automobile manufacturing, food and beverage and other industries on the production line.

Power distribution: Monitor and control the status of digital switches and circuit breakers in the power system to ensure the stable operation and safe distribution of the power system.

Building automation: Control the digital signals in the building, such as security systems, lighting control, access control systems, etc., to achieve intelligent management and energy-saving operation of building facilities.

Manufacturing: Connecting and controlling the digital input and output devices in manufacturing equipment, enabling the monitoring of equipment, helping to improve production efficiency, ensure product quality and optimize production processes.

Traffic system: Used in traffic signal control system, elevator control, rolling gate control, etc., to ensure the normal operation of traffic facilities and the safe transportation of personnel and goods.

To determine the fault of ABB IDPG 940128102 module, proceed from the following aspects: Visual inspection Module shell: Check whether the module shell has obvious damage, such as cracks, deformation, etc. These physical damages can affect the electrical components inside the module and cause failure. Indicator status: There are usually various indicators on the module, such as the power indicator, running indicator, and fault indicator. Under normal circumstances, the power indicator should be on after power. If the power indicator is off, the power supply may be faulty or the internal power circuit of the module is faulty. The running indicator should be normally blinking or steady on according to the working status of the module. If the running indicator is abnormal, for example, off or the blinking frequency is abnormal, the module may not work properly. When the fault indicator is on, it directly indicates that the module has detected a fault. Connection port: Check the connection port of the module, including the power port, communication port, and input and output port, for loosening, oxidation, or scorch marks. Loose connections can lead to unstable or interrupted signal transmission, and oxidation and scorch marks can indicate problems such as overcurrent and overheating. Electrical parameter measurement Power supply voltage: Use a multimeter to measure the input power supply voltage of the module and check whether it is within the specified working voltage range of the module. If the voltage is abnormal, such as too high, too low, or unstable, the module may not work properly. Signal input and output: For modules with input and output functions, use appropriate test equipment (such as signal generators, multimeters, etc.) to detect whether the input signal can be correctly received and processed by the module, and whether the output signal of the module meets the expectations. For example, if the module is an analog input module, you can input a known analog signal and then measure whether the output of the module corresponds to the input signal; If it is a digital output module, you can output signals through the control module to check whether the connected load is responding normally. Communication test Communicate with other devices: If the module communicates with other devices (such as controllers, computers, etc.) through the communication interface, check whether the communication is normal. You can use communication test tools or related software to try to send and receive data to see if you can successfully establish a communication connection and exchange data. If the communication fails, the module's communication interface may be faulty, the communication parameters are set incorrectly, or the communication line is faulty. Communication Protocol Check: Verify that the communication protocol used by the module is correctly configured and matches the connected device. Incorrect communication protocol Settings may cause the communication to fail. Functional testing Simulation of actual working conditions: under the premise of safety, simulate various working conditions of the module in actual work, and observe the operation of the module. For example, if the module is used to control the operation of a device, you can try to start or stop the device, adjust the operation parameters of the device, and other operations to see whether the module can accurately execute the corresponding control instructions, and feedback the correct status information. Compare normal status: You can compare the running parameters and status of normal modules of the same model with those of the module to be detected. For example, comparing the input and output response time and signal strength of the two devices may help you identify the fault. Fault code analysis Some advanced ABB modules generate specific fault codes when faults occur. By referring to the user manual or technical documentation of the module, you can understand the meaning of these fault codes and quickly locate the fault cause. If the cause of the module failure cannot be determined by the above methods, it is recommended to contact ABB's technical support team or professional maintenance personnel, who can use more professional testing equipment and methods for further diagnosis and repair.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB