Description

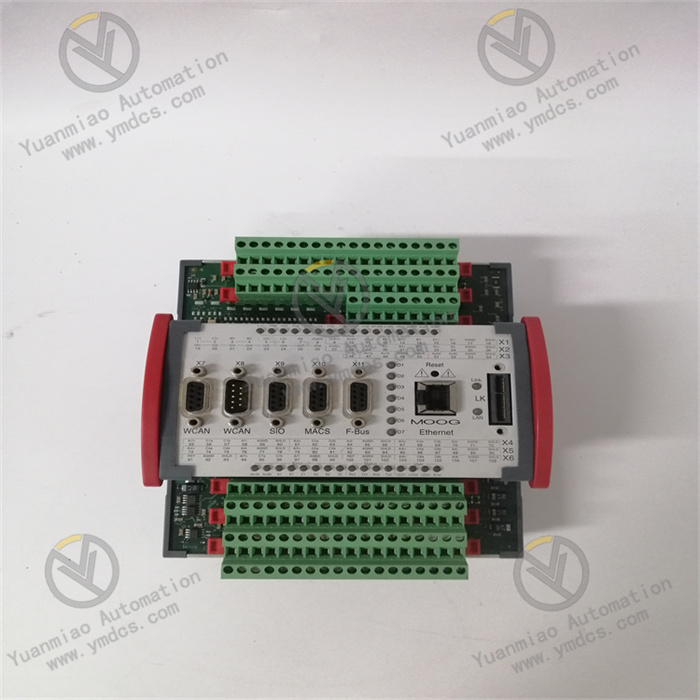

ABB OCAH 940181103 is a versatile, high-performance module. Functional characteristics Powerful processing capacity: As a high-performance processor unit, equipped with a powerful multi-core processor and a large amount of memory, it can quickly process a large amount of data, and can handle multiple tasks at the same time to meet the requirements of industrial control applications for data processing speed and accuracy. Rich communication functions: Support Ethernet, Profibus, Modbus and other communication protocols, convenient interface communication with various I/O modules and other devices, to achieve seamless integration of the system and rapid data transmission. Flexible programming and configuration: With programmable controller (PLC) technology, various logic control and data processing functions can be programmed. Support a variety of programming languages and development environments, convenient for users to develop and customize the system, can be flexibly configured according to different control system requirements. Perfect protection and monitoring: with over current, over voltage, under voltage and other protection functions, can effectively prevent the equipment from being affected by voltage fluctuations or abnormal conditions. At the same time, it has intelligent monitoring and management functions, and communicates with the host computer through serial port or network, so as to realize remote monitoring, configuration and fault diagnosis, and improve the maintainability and management efficiency of the equipment.

Performance advantage

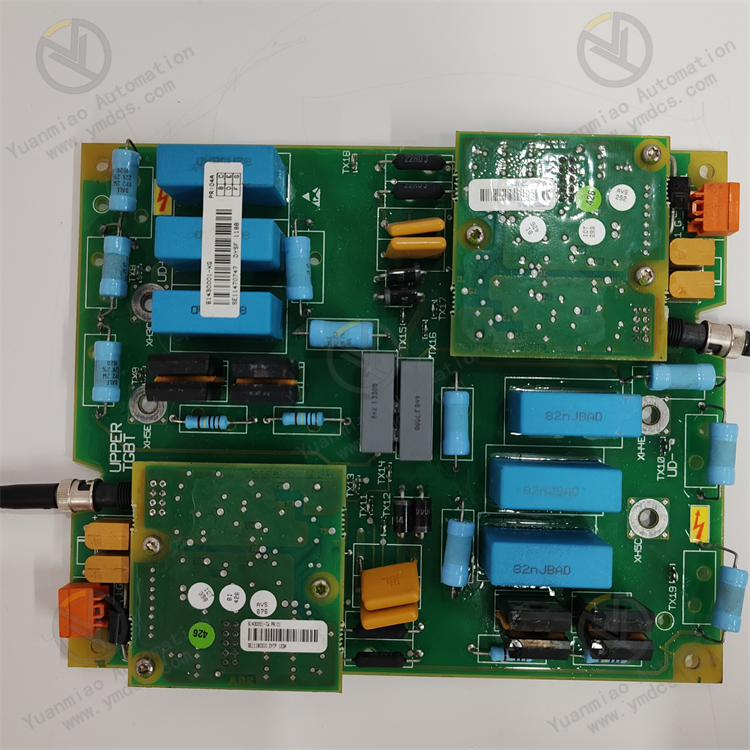

High reliability: The use of high-quality electronic components and materials manufacturing, built-in redundancy function, even in the case of hardware defects, to ensure high availability and reliability of the system, can be stable operation in harsh industrial environments.

High precision and stability: With high precision signal processing capabilities and stable output characteristics, it can ensure the accuracy and stability of control, and ensure the accurate operation of industrial equipment.

Application field

Industrial automation: Widely used in oil and gas, power generation, chemical processing, metal processing, food and beverage, pharmaceutical, paper, textile, automotive and other industries to meet the needs of a variety of industrial control and automation applications.

Power system: It can be used for the monitoring and control of the power system to achieve remote monitoring, control and management of the power equipment to improve the stability and reliability of the power system.

Other fields: It is also used in railway, ship and other fields to provide reliable support for the control system of related equipment and realize the automatic operation and management of equipment.

General installation steps for ABB OCAH 940181103 module:

Preparation before installation

Check module models and specifications: Ensure that ABB OCAH 940181103 meets application requirements and check whether the module is damaged or deformed.

Tools and materials: Prepare required tools, such as screwdrivers and wrenches, and possible installation supports, bolts, and nuts.

Disconnect the power supply: Before installing a module, disconnect the power supply of related devices to ensure the safety of installation and prevent electric shock or other electrical accidents.

Select installation location

Environment requirements: Select an appropriate installation position that is away from harmful environments such as water, humidity, high temperature, corrosive substances, and strong electromagnetic interference sources to ensure the normal operation and service life of the module.

Space requirements: Ensure that the installation position has enough space to facilitate module installation and subsequent maintenance operations. At the same time, consider the heat dissipation requirements of the module. There should be no objects around that hinder air circulation.

Install module

Secure the module: If the module needs to be installed on a support or panel, use a tool such as a screwdriver or wrench to secure the module to the support or panel through the mounting holes on the module. Ensure that the mounting screws are tightened to prevent the module from loosening due to vibration during operation.

Connecting cables: Connect cables according to the interface type of the module and the actual application requirements. For example, connect power cables, communication cables, and input and output signal cables. When connecting cables, ensure that the connector of the cable matches the interface of the module. Ensure that the cable is securely connected, and connect cables correctly to prevent the module from working properly or damaging the device.

Electrical connection

Power connection: Connect the power input terminal of the module to an appropriate power supply to ensure that the power supply voltage meets the rated voltage requirements of the module. When connecting the power supply, pay attention to the correct connection of the positive and negative terminals to avoid connecting the reverse power supply. If a module needs to be grounded, the grounding terminal must be grounded reliably to ensure the safe running and stable performance of the device.

Communication connection: If the module needs to communicate with other devices, connect corresponding communication cables according to the communication protocol and interface type used, and set necessary communication parameters. For example, if Ethernet communication is used, connect the network cable and set parameters such as the IP address, subnet mask, and gateway of the module. For Profibus communication, connect the Profibus cable and set parameters such as the station address.

Inspection and testing

Appearance check: After the installation is complete, check whether the module is firmly installed, whether the cable is tightly connected, and whether it is loose, fallen off, or damaged. In addition, check whether the indicators on the module, such as the power indicator and running indicator, are on normally. If the fault indicator lights up, it is necessary to find the cause of the fault and eliminate it according to the module manual or relevant technical data.

Functional test: Before powering on, the module is tested. You can use relevant test tools or software to simulate the input signal and check whether the output of the module meets expectations; Or through the communication interface, communicate with other devices to ensure that the module can receive and send data normally. If the module has specific functions, such as data acquisition, control output, etc., it is also necessary to carry out corresponding functional tests to verify whether the performance of the module is normal.

Power-on operation

Power on check: After confirming that the module is installed correctly, the electrical connection is correct, and the function test is normal, switch on the power supply. Observe the running status of the module, including indicator status and abnormal sound or odor. If any abnormal situation is found, the power supply should be cut off immediately for checking and troubleshooting.

System integration testing: If the module is integrated in a larger system, system integration testing is required. Check whether the cooperation between the module and other devices is normal, whether the data transmission is accurate, and whether the control function is realized. During the testing process, the operating procedures and testing procedures of the system should be followed to ensure the stability and reliability of the system.

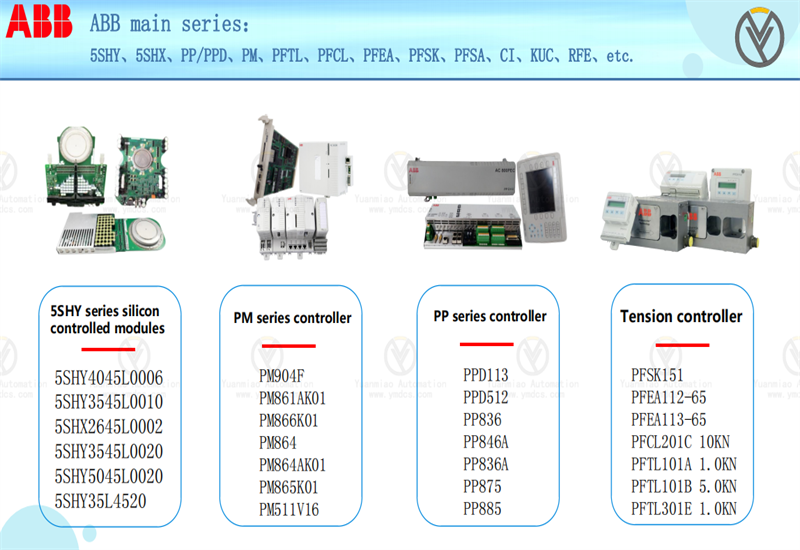

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB