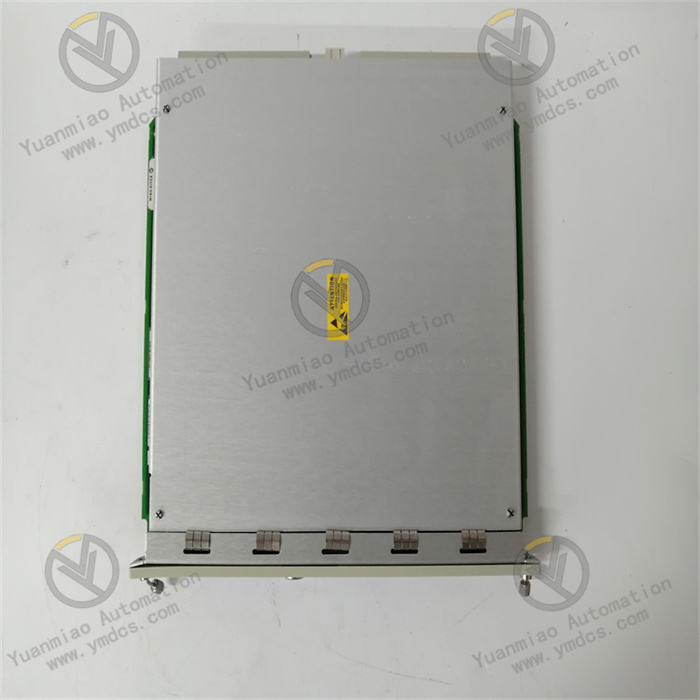

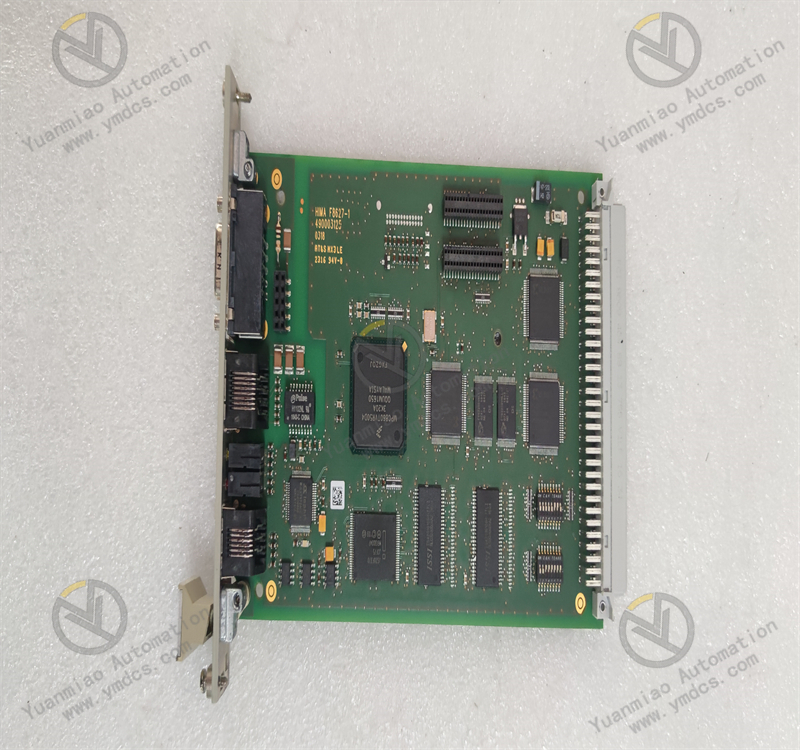

Description

The ABB CI854A 3BSE030221R1 is a PROFIBUS-DP /V1 interface module for industrial automation, part of ABB's 800xA family. Functional characteristics The PROFIBUS-DP /V1 interface module is used to connect the PROFIBUS-DP slave device to the AC 800M controller, supporting up to 124 slave devices and data transmission rates up to 12Mbit/s. There are two PROFIBUS DP ports for connecting up to 32 PROFIBUS devices and an integrated power supply for powering PROFIBUS devices. Data processing efficiency: data processing functions may be available to perform data processing operations within the module, reducing the burden on the control system. Support a variety of communication protocols, such as Ethernet, PROFIBUS, MODBUS, etc., to facilitate data exchange with different devices. Easy configuration and maintenance: The configuration tool can be used to set and monitor, easy to operate. The module is compact in design, easy to install, and has fault diagnosis function, can detect and report communication problems, easy to maintain.

Performance advantage

High reliability: Industrial design, with excellent anti-interference ability and stability, to ensure the stability and continuity of data communication, can be in harsh industrial environment for a long time stable operation.

Strong real-time: real-time requirements in industrial applications can be well met to ensure timely data exchange.

Application field

Process control and monitoring: It is widely used in the process control and monitoring system of chemical, petrochemical, pharmaceutical and other industries, which can achieve accurate monitoring and control of the production process.

Power system control: used for monitoring and control of power plants, substations and distribution systems to ensure the stable operation of the power system.

Manufacturing automation: Suitable for automated production lines, can improve production efficiency and product quality.

Building automation: It can be used to control the air conditioning, lighting and security systems of buildings to achieve intelligent management.

Other fields: It is also used in water treatment and environmental monitoring, food and beverage industry, mining and metal processing, transportation system and other fields, which can meet the needs of automatic control in different scenarios.

ABB CI854A 3BSE030221R1 module installation precautions:

Installation environment

Temperature and humidity: Ensure that the installation environment temperature is within the allowable operating temperature range of the module. Generally, the temperature ranges from -20 ° C to + 60 ° C. Do not install the module at a temperature too high or too low. At the same time, the ambient relative humidity should be in the appropriate range, usually not more than 95% (no condensation), too high humidity may lead to electrical short circuit or component corrosion.

Cleanliness: Choose a clean environment without large amounts of dust and corrosive gases. Dust may accumulate inside the module, affecting heat dissipation and electrical performance; Corrosive gases may damage the module's electronic components. If the installation environment is harsh, it is recommended to use a control cabinet with a higher protection level.

Electromagnetic interference: away from strong electromagnetic interference sources, such as large motors, transformers, inverters and other equipment. Strong electromagnetic interference may affect the communication and data processing functions of the module, resulting in communication errors or data loss. If you cannot avoid being near the interference source, take effective shielding and grounding measures.

Installation position

Space requirements: Reserve enough space for installing the module and ensure that there is good ventilation around the module for heat dissipation. In general, the module should leave at least 50mm of space left and right. At the same time, considering the convenience of subsequent maintenance and overhaul, sufficient operating space should be left around the module.

Vertical installation: It is usually recommended to install the module vertically in the control cabinet, which is conducive to air convection and heat dissipation. If the module is installed horizontally, the heat dissipation effect of the module may be affected, causing the module temperature to rise, which affects the performance and service life of the module.

Electrical connection

Power connection: Before connecting the power supply, make sure that the power supply voltage matches the rated voltage of the module (usually 24V DC). When connecting the power supply, pay attention to the positive and negative polarity to avoid module damage caused by reverse connection. Use the power cord of appropriate specifications and ensure that the connection is firm to prevent poor contact or electrical failure caused by loosening.

Communication connection: When connecting the PROFIBUS-DP communication cable, connect it in the correct wiring mode and ensure that the shield layer of the cable is well grounded to reduce electromagnetic interference. The length of the communication cable should meet the requirements of the module. Too long a cable may cause signal attenuation and communication errors. At the same time, make sure to connect to the correct communication port, and set the communication parameters correctly, such as baud rate, slave station address, etc.

Grounding: The grounding terminal of the module should be grounded reliably, and the grounding resistance should be smaller than the specified value (generally no more than 4 ohms). Good grounding can effectively prevent the impact of electrical interference and lightning strikes on the module, and improve the stability and safety of the system.

Installation operation

Esd prevention: When installing and operating a module, take ESD measures, such as wearing an ESD bracelet and operating the module on an ESD workbench. Static electricity may damage the electronic components of the module, resulting in module faults.

Firmly fixed: The module is firmly fixed in the control cabinet with appropriate mounting screws or guide rails to prevent the module from loosening due to vibration during operation. The mounting screws should be tightened without excessive force, so as not to damage the housing or internal components of the module.

Avoid physical damage: During the installation, be careful to avoid physical damage to the module, such as collision and extrusion. The shell and interface of the module are fragile, and physical damage may affect its performance and normal use.

Post-installation inspection

Appearance check: After the installation is complete, check whether the appearance of the module is damaged, whether the cable is firmly connected, whether it is loose, detached, or damaged.

Electrical check: Use tools such as a multimeter to check whether the power supply voltage is normal, communication lines are properly connected, and grounding is normal. Ensure that all electrical connections meet the requirements without short circuit, open circuit and other problems.

Functional test: Before powering on, double check that all connections are correct. After the power is powered on, observe the indicator status on the module and judge whether the module wo

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB