Description

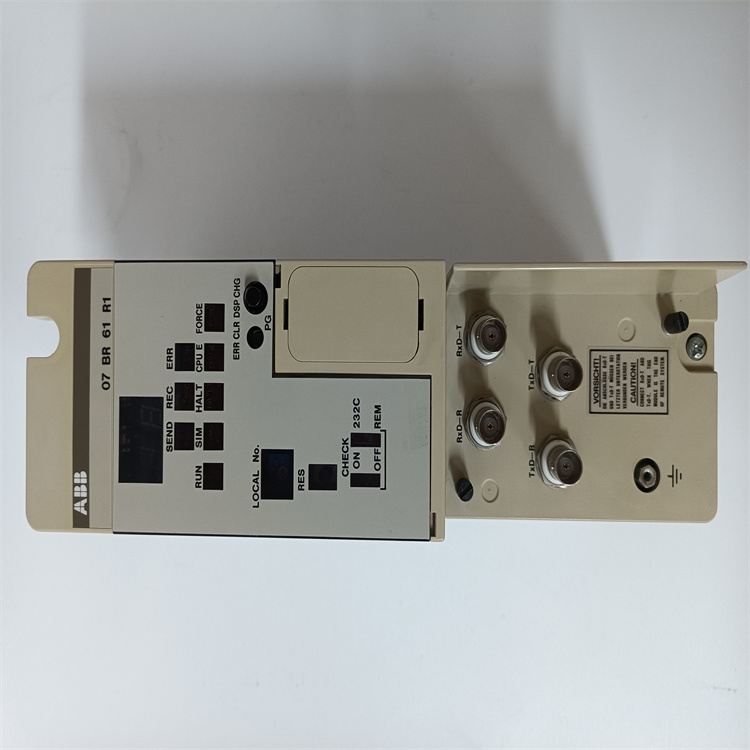

ABB CM772F 3BDH000368R0001 is a DCS system module used for industrial automation control.

Functional Features:

Strong Communication Ability: It is a PROFIBUS DP master module, supporting multiple communication protocols such as Modbus, Profibus, Ethernet, etc. It can conveniently communicate with the upper computer and other devices to achieve data transmission and remote control.

Rich Inputs and Outputs: It supports various types of input and output signals, including digital input and output, analog input and output, RTD (Resistance Temperature Detector) and thermocouple input, etc. It can meet the connection requirements of different on-site devices and can realize the collection, processing, and control of various parameters in the production process.

High Reliability: Using industrial-grade components, it has high reliability and stability and can operate stably in harsh industrial environments. The module may have functions such as self-diagnosis and redundancy to improve the reliability and availability of the system.

Physical Characteristics:

Compact Size: The product has a net depth of 75 millimeters, a net height of 135 millimeters, and a net width of 28 millimeters. It is a compact device that occupies little space and is easy to install in various equipment cabinets or control boxes.

Light Weight: The product has a net weight of 0.1 kilograms, making it easy to carry and install.

Application Fields:

Industrial Automation: It can be used in PLC control systems, SCADA systems, etc., to achieve the monitoring and control of production equipment, improving production efficiency and quality.

Process Control: In process control systems such as chemical, power, and water treatment industries, it can collect and process parameters such as temperature, pressure, and flow rate in the production process to achieve precise control of the production process.

Other Fields: It can also be applied to industries such as pharmaceuticals, papermaking, CNC (Computer Numerical Control) machine tools, etc., helping users achieve efficient, reliable, and precise automation control and monitoring.

Installation Steps

Preparation Work: Ensure that the installation environment meets the requirements, such as suitable temperature, humidity and other conditions, and there is no strong electromagnetic interference near the installation location. At the same time, prepare the required tools, such as a screwdriver.

DIN Rail Installation: This module usually adopts the DIN rail installation method. First, snap the upper part of the module's rail clip (the part with the retaining spring) onto the 35mm DIN rail, and then snap the lower part into the rail with a little force to ensure that the module is stably and reliably fixed on the DIN rail in a balanced manner.

Power Connection: Connect the appropriate power supply according to the power requirements of the module. Generally speaking, pay attention to the polarity and voltage range of the power supply to ensure that the rated voltage of the input power supply matches the rated voltage of the module itself, which is usually 24V DC. If it is a DC power supply, confirm that the positive and negative poles are correctly connected. Crimp terminals can be used for wiring to avoid directly connecting the exposed stranded wires to the terminals.

Communication Cable Connection: Connect the CM772F module with other devices (such as controllers, upper computers, etc.) through the corresponding communication cables, such as PROFIBUS bus cables, according to the actual application requirements. Ensure that the cables are firmly connected and the wiring is reasonable, and avoid running parallel to high-voltage lines to reduce interference.

Configuration Steps

Hardware Configuration: Perform hardware configuration of the CM772F module in the relevant automation control system software. For example, in ABB's control system, open the corresponding engineering configuration software, add the CM772F module, and set its basic information such as the station address and communication parameters to make it match the actual physical connection and system requirements.

Communication Protocol Configuration: Configure the communication protocol of the module according to the communication requirements with other devices. Select the PROFIBUS DP protocol, for example, and set the relevant protocol parameters such as baud rate, data bits, stop bits, and parity bits to ensure that the protocol settings are consistent with those of the communication partner to achieve normal data communication.

Input and Output Configuration: Configure the input and output signals of the module according to the actually connected on-site devices and control requirements. Define the parameters such as the type, range, and address of digital input, digital output, analog input, analog output and other signals. For example, if a temperature sensor is connected to the analog input channel, it is necessary to set the range of this channel to match the output range of the sensor and specify its address in the system for data collection and processing in the program.

Function Block Configuration (if applicable): If the module supports function block programming, configure the corresponding function blocks according to the specific control tasks. For example, set the parameters of function blocks used for data processing, logical operation, PID control, etc. to achieve precise control and monitoring of the production process.

Download and Debugging: After completing the above configuration, download the configured project to the controller or related devices and carry out debugging. Check whether the module can work normally, whether the communication with other devices is stable, and whether the input and output signals are accurate. If there are any problems, gradually troubleshoot and solve them according to the error prompt information or the phenomena during the debugging process, such as checking whether the cable connection and parameter settings are correct.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB

![]()