Description

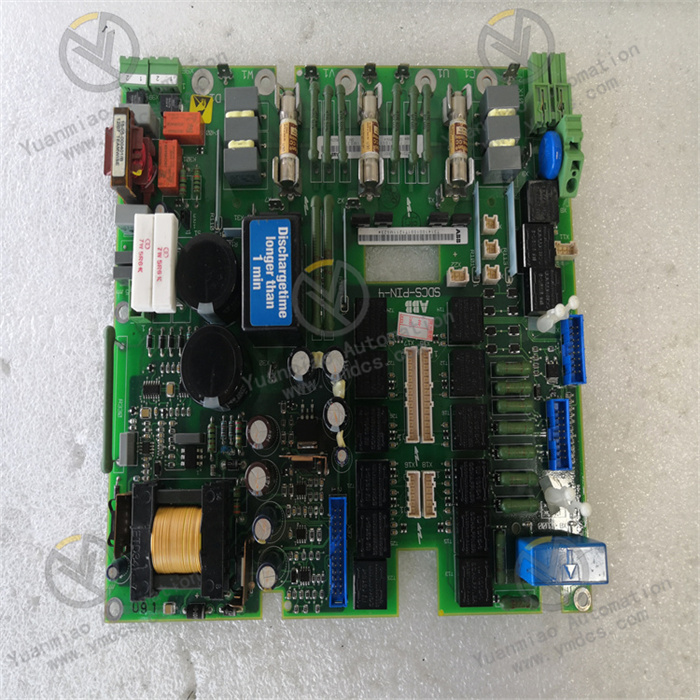

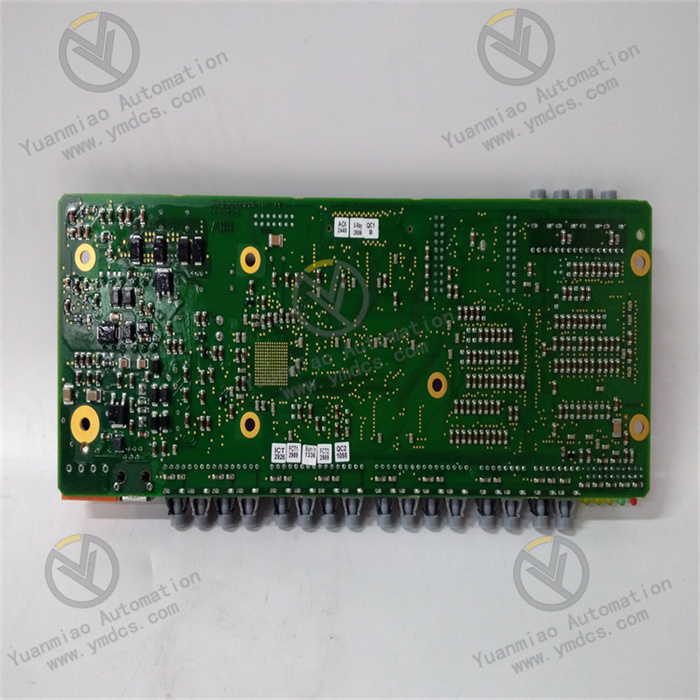

The ABB PFEA112-20 3BSE030369R0020 is a tension controller used for industrial automation. Appearance and Dimensions: The module features a compact design with dimensions of 105mm×98mm×35mm and weighs approximately 200g, making it easy to install in industrial environments with limited space. Power Requirements: The operating voltage is 24V DC. This stable DC power input can ensure stable power support for the device in different industrial scenarios and guarantee its reliable operation. Functional Features: Precise Tension Control: By adopting advanced control algorithms and technologies, it can provide precise and stable tension control during the industrial production process, ensuring that the materials maintain an appropriate tension during the transportation, processing, and other processes, reducing the stretching, deformation, or loosening of the materials, and improving the product quality. Multiple Signal Processing: It is equipped with four analog input channels, which can accurately measure environmental conditions or process variables, such as the signals from tension sensors, to achieve real-time monitoring and feedback control of the tension. At the same time, it has high-speed digital outputs, which can accurately handle fast switching tasks and ensure the accurate transmission of control signals. Communication Capability: It supports multiple communication protocols, such as Modbus RTU, RS-485, CANopen, etc., which facilitates seamless integration with other industrial control systems, enables information interaction and collaborative work between devices, and is convenient for centralized monitoring and management across the entire production line. Protection Level: The protection level is IP20, which can prevent the intrusion of objects larger than 12.5mm. It is suitable for general industrial environments but is not suitable for places with harsh conditions such as dust and water droplets. Application Fields: It is widely applied in industries such as manufacturing, printing, packaging, and textiles, and plays an important role in the process steps that require tension control of materials, such as the production processes of paper, films, cables, and other materials.

Operation Guide for ABB PFEA112-20 3BSE030369R0020:

Basic Operations

Navigation and Confirmation: Navigate through the menus and confirm parameters via the buttons on the panel. For example, use specific buttons to move between different menu options, and press the confirmation button to enter sub-menus or save the settings.

Changing Numerical Values and Parameters: Use the relevant buttons to change numerical values and parameters. For instance, press the up and down arrow buttons to adjust the numerical values, and press the confirmation button to save the changes after selecting the parameters.

Menu Operations

Menu Overview: It includes multiple functional menus, such as Basic Settings, Quick Settings, Service Menu, etc.

Basic Settings: Parameters such as language, unit, coil width, decimal places, and target can be set. For example, select the required operation language in the language settings; set the unit according to the actual measurement requirements, such as N, kN, etc.; set the coil width to match the actual application scenario; control the display accuracy of the measured values by adjusting the decimal places; set target parameters, such as the rated load, etc.

Quick Settings: There are two quick setting methods: using hanging weights and winding gain. When using hanging weights, hang the weights of known weights at the relevant positions according to the operation steps, and the system will automatically calibrate the parameters according to the weight of the weights; when using the winding gain method, appropriate winding gain parameters need to be set according to the winding characteristics of the material and the actual tension requirements to quickly achieve the preliminary setting of the tension control. You can also check the signal polarity and functionality of the load cell here to ensure that the sensor is correctly connected and working properly.

Service Menu: It contains options such as Maximum Load/Current Offset, Reset A/B, Simulation Function, etc. The Maximum Load/Current Offset function is used to view and set the maximum load value and the current offset of each load cell; Reset A/B can set "Maximum Load A" or "Maximum Load B" to zero, which is convenient for use when replacing the load cell or performing calibration operations; the simulation function can be set to on or off. When it is turned on, it can simulate the measured values of the load cell, which is used for system debugging and troubleshooting. For example, set the simulated percentage value to replace the actual measured value of the load cell, which is convenient for checking the running status of the system under different tension conditions.

Operation during Running

Startup and Shutdown: According to the device connection and installation requirements, after turning on the power supply, start the device by pressing the start button on the operation panel. The device will perform self-check and initialization operations, and then enter the normal running state; when shutting down the device, stop the relevant production process first, and then press the shutdown button on the operation panel to cut off the power supply.

Normal Operation: During the operation, the display will show the measured values, such as the sum, individual A and B values, and the differential signal, etc. You can view the corresponding tension values in different measurement modes. For example, in the standard coil (two load cells) measurement mode, the overall tension situation of the coil is displayed, and in the single-side A or single-side B measurement mode (one load cell), the tension situation of a single side of the coil can be viewed respectively. At the same time, according to the actual application requirements, you can switch between different menu interfaces by using the function keys on the operation panel to view and set various parameters to ensure that the tension control meets the production process requirements.

Fault Handling

Error and Warning Messages: During the operation of the device, if there are any faults or abnormal situations, error and warning messages will be displayed on the display. According to the message prompts, the type of fault and the possible causes can be quickly located. For example, if "Flash Memory Error" is displayed, there may be a problem with the flash memory of the device; if "Load Cell Excitation Error" is displayed, it is necessary to check whether the power supply and connection of the load cell are normal. For different error and warning messages, you can refer to the troubleshooting guide in the device manual and take corresponding solutions, such as checking the device connection, replacing the faulty components, etc.

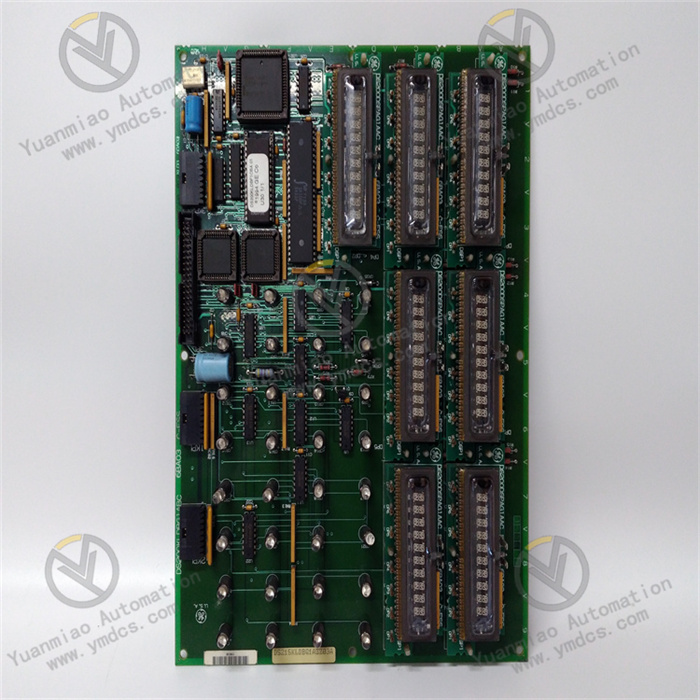

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB