Description

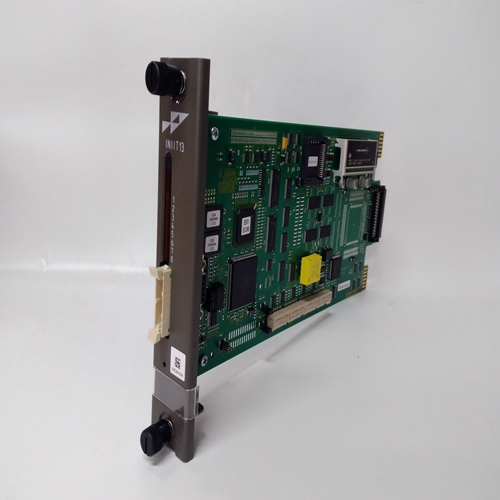

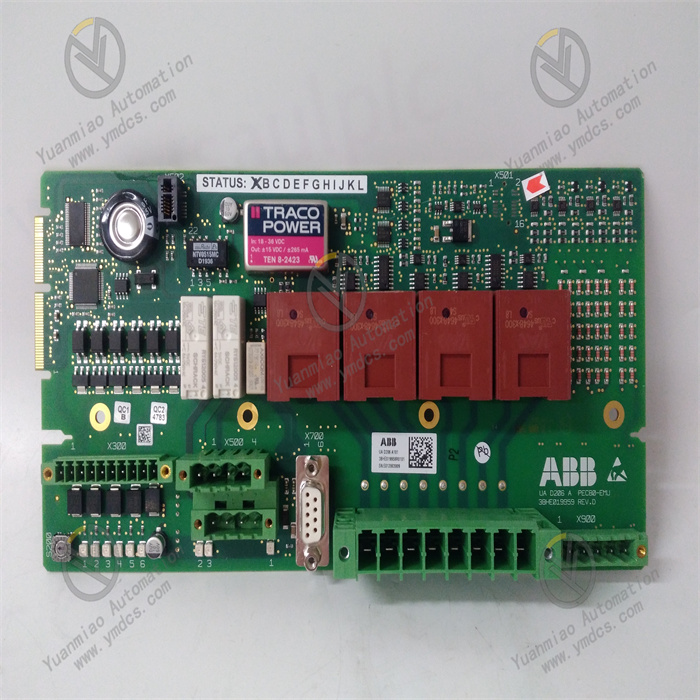

ABB PM902F 3BDH001000R0005 is a medium-sized basic CPU unit of the Freelance AC 900F controller series. Functional Features Powerful Processing Capacity: Equipped with an 800MHz CPU clock, it has 24MB of controller memory, 8MB of battery-buffered SRAM, and 16MB of DRAM. It can support up to 1,500 I/Os, quickly process a large amount of data, and meet the requirements of complex industrial control tasks. Rich Communication Interfaces: It has 4 Ethernet interfaces and also comes with 2 slots for assembling communication interface modules. It can be expanded into a variety of standard bus protocols, such as Profibus DP-V1, DeviceNet, CANopen, etc., facilitating high-speed data exchange and communication with other devices and systems. Support for Multitasking: It can handle multiple control tasks simultaneously, ensuring the orderly operation of various control functions in the industrial process and improving the overall efficiency and reliability of the system. Counting and Pulse Control Functions: It can record the number of input pulse signals, which is used to monitor the operating status of equipment or the production process. At the same time, it supports the control of pulse frequency and width, and can also generate pulse signals regularly to meet the precise control requirements of pulse signals in different industrial control scenarios. Alarm and Fault Detection: It usually has alarm and fault detection functions. It can monitor its own operating status, trigger an alarm in case of an anomaly, and record relevant fault information, making it easy for maintenance personnel to quickly locate and troubleshoot faults. Performance Parameters Power Supply Requirements: It requires an external 24VDC power supply, with an allowable range of 18 - 30VDC. Processing Speed: With a high-frequency CPU and optimized hardware design, it has a fast data processing speed, can quickly respond to changes in input signals, and promptly output control instructions. Accuracy: It has a high accuracy in the collection and processing of analog quantities, can accurately reflect the changes in actual physical quantities, and ensure the accuracy of system control. Physical Characteristics Dimensions: The net depth/length of the product is 95 millimeters, the net height is 152 millimeters, and the net width is 227 millimeters. It has a compact size and is easy to install in various industrial control cabinets or equipment. Weight: The net weight of the product is approximately 1.1 kilograms. It is light in weight, making it convenient for installation and handling. Reliability: Adopting industrial-grade design and manufacturing standards, and after strict testing and verification, it has high stability, high reliability, and a long service life, and is suitable for harsh industrial environments. Application Fields Power Industry: It can be used in the fields of power system monitoring, generator control, and power transmission and transformation automation. Metallurgical Industry: It is suitable for scenarios such as furnace temperature control, quality inspection, and sintering machine control. Chemical Industry: It can be applied to the links of chemical production process control and safety monitoring.

Debugging Methods 1. Hardware Inspection Power Supply Inspection: Ensure that the power supply of ABB PM902F 3BDH001000R0005 is normal, and the voltage is within the allowable range (usually 24VDC, with an allowable range of 18 - 30VDC). Check whether the power supply lines are firmly connected and whether there are any short circuits or open circuits. Communication Connection Inspection: Check whether the communication connections between the controller, the computer, and other devices are normal. For Ethernet connections, check whether the network cable is properly plugged in and whether the IP address settings are correct; for other communication interfaces, such as Profibus, etc., check whether the communication cables and interfaces are working properly. I/O Connection Inspection: Check whether the connections of input and output signals are correct, and whether the sensors and actuators are working properly. Tools such as a multimeter can be used to measure parameters such as the voltage and current of the input signals, and check whether the output signals can correctly drive the actuators.

2. Program Download and Monitoring Program Download: After completing the program writing in Automation Builder, download the program to the ABB PM902F 3BDH001000R0005 controller. During the download process, ensure that the controller is in a downloadable state and that the communication connection is normal. Online Monitoring: After the download is completed, enter the online monitoring mode. In Automation Builder, you can view real-time information such as the values of variables and the status of function blocks. By monitoring this information, you can determine whether the program is running normally. For example, observe whether the values of input variables are consistent with the actual measured values of the sensors, and whether the values of output variables can correctly control the actuators.

3. Functional Testing and Debugging Single-Point Testing: Conduct single-point testing on the input and output points, that is, apply signals to each input point separately and observe whether the corresponding output points have corresponding changes. Through single-point testing, you can check whether the I/O module is working properly and whether the processing of input and output signals in the program is correct. Logic Testing: Test the logic functions of the program according to the design requirements of the control logic. For example, for a sequential control program, check whether each step can be executed in the预定的 order and whether the transition conditions can be correctly triggered. Parameter Adjustment: If the control effect is not satisfactory during the testing process, it may be necessary to adjust the parameters in the program. For example, for the PID control function block, it may be necessary to adjust the proportional, integral, and derivative parameters to achieve a better control effect.

4. Fault Troubleshooting and Handling

Alarm Information Viewing: When a fault occurs in the controller, corresponding alarm information will be generated. You can view these alarm messages in Automation Builder and locate the cause of the fault according to the prompts of the alarm messages. For example, the alarm message may indicate that a certain input/output module is faulty, a communication fault occurs, etc.

Step-by-Step Troubleshooting: If the alarm information cannot clearly identify the cause of the fault, a step-by-step troubleshooting method can be adopted. For example, first check whether the hardware connection is normal, and then check whether there are any errors in the program logic. You can help troubleshoot the fault by modifying the program, adding debugging information, and other means.

Main brands include: ABB, Bailey, GE, FOXBORO, Invensys TRICONEX, Bentley BENTLY, A-B Rockwell, EMERSON EMERSON, B&R, MOTOROLA, FUANC, REXROTH, KUKA, HONEYWELL, NI, DEIF, Yokogawa, WOODWARD WOODWARD, Ryan, SCHNEIDER SCHNEIDER, Yaskawa, MOOG, EPRO, PROSOFT and other major brands

[Disclaimer]

Guizhou Yuanmiao Automation Equipment Co., LTD. We sell new products and discontinued products, independent channels to purchase such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, distributor or representative of the featured products on this website. All product names/product images, trademarks, brands and logos used on this website are the property of their respective owners. Descriptions, descriptions or sales of products bearing these names, pictures, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/ABB