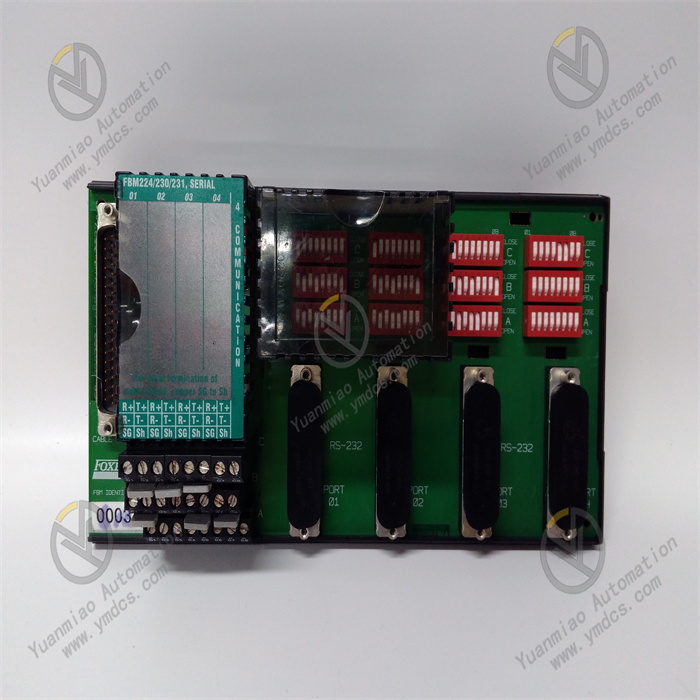

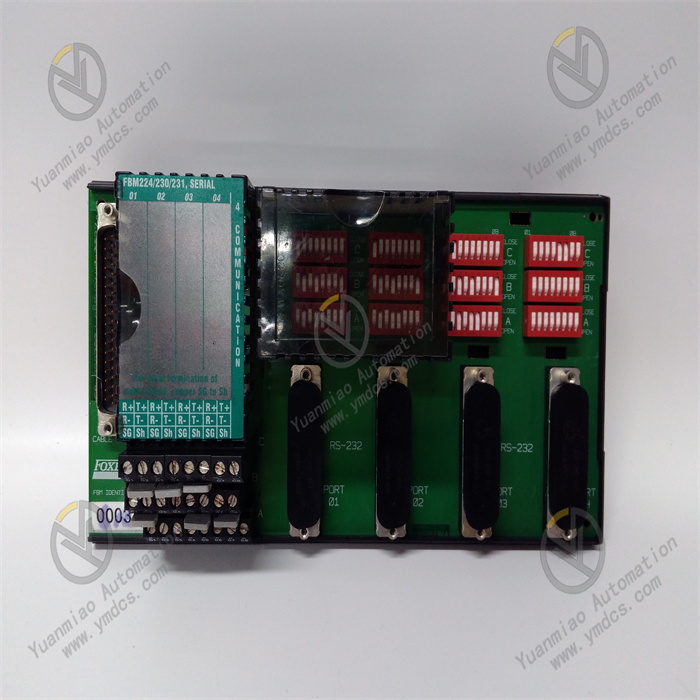

Description

In terms of functions: It may be used in a certain link of the industrial automation control system, such as data collection, signal processing, execution of control logic, etc. For example, the FBM232 P0926GW is a field device system integration module, which is used to integrate the data of field devices into the Foxboro Evocontrol database. The P0926GL - 0C may also have similar data processing and transmission functions. It may be responsible for collecting specific types of data in the industrial process and transmitting it to the central control system or other relevant devices.

In terms of electrical characteristics: The input and output signals may have specific voltage and current ranges to meet the requirements of different industrial field signals. For instance, some FOXBORO cards support discrete input and output with multiple voltage levels. For example, the P0926CC supports discrete output signals at voltages of 15 to 60Vdc, 120Vac/125Vdc, and 240Vac. The P0926GL - 0C may also have a similar wide voltage support range to facilitate connection with various external devices.

In terms of environmental adaptability: Considering the diversity and complexity of industrial environments, it may have good environmental adaptability, be able to operate stably within a certain temperature and humidity range, and have anti-interference capabilities. Just as the FBM232 P0926GW can be used in GG3-level (harsh) environments, the P0926GL - 0C may also be able to operate reliably in relatively harsh industrial environments.

- Check the appearance of the module for any damage, deformation, or missing components. If there are any issues, contact the supplier immediately for replacement.

- Confirm the interface type and connection method of the module, and prepare the corresponding connection cables and interface accessories according to actual requirements.

- Insert the module smoothly into the corresponding slot or mounting bracket, ensuring good contact and a firm connection between the module and the slot or bracket. If the module needs to be fixed with screws, use appropriate tools to tighten the screws, but be careful not to apply excessive force to avoid damaging the module or the mounting bracket.

- Connect the input and output signal lines according to the module's instruction manual, ensuring correct wiring and avoiding short - circuits, open - circuits, or incorrect connections. After wiring is completed, check again whether the line connections are secure to prevent unstable signal transmission due to loose connections.

- Connect the power supply line, ensuring that the voltage and frequency of the input power supply meet the requirements of the module. Generally, the input voltage range for FOXBORO cards is 24 volts DC ±5%, - 10%. After the connection is completed, check the power supply line for any leakage or poor contact.

- Regularly check the operating status of the module by observing whether the indicator lights on the module are lit normally to determine if the module is working properly. If any abnormal indicator lights are found, refer to the instruction manual in time or contact the technical support staff for troubleshooting.

- Check the connection lines of the module for any looseness, damage, or aging. If any issues are found, tighten or replace the lines promptly.

- Clean the dust and dirt on the surface of the module by gently wiping it with a clean, soft cloth. Avoid using cleaners containing corrosive components.

- Conduct a comprehensive inspection and test of the module at regular intervals (e.g., every six months or one year). Use professional test equipment to detect the input and output signals of the module to ensure that its performance indicators meet the requirements.

- Check the heat dissipation situation of the module to ensure that the heat dissipation channels are unobstructed and to avoid overheating of the module due to poor heat dissipation. If the module temperature is found to be too high, promptly find the cause and take corresponding measures, such as cleaning the cooling fan or improving the ventilation conditions of the installation environment.

- Check the parameter settings of the module to ensure that they are consistent with the actual application requirements. If necessary, adjust the parameters according to changes in the production process, but back up the original parameter settings before adjustment so that they can be restored if needed.

【 Disclaimer 】

We sell new products and discontinued products, independent channels to buy such special products. Guizhou Yuanmiao Automation Equipment Co., Ltd. is not an authorized distributor, dealer or representative of the products featured on this website. All product names/product images, trademarks, brands and microlabels used on this Website are the property of their respective owners. Descriptions, depictions or sales of products with such names/images, trademarks, brands and logos are for identification purposes only and do not imply any association or authorization with any rights holder.

This article is from the official website of Guizhou Yuanmiao Automation Equipment Co., LTD. Please attach this link: http://www.ymdcs.com/Foxboro/

![]()